3.7 The effects of materials' hierarchical structure

In their exploration of smart materials with tunable friction, scientists have made interesting observations regarding the structure of materials. In experiments they found that friction forces are the result of various types of complex multi-scale interactions between sliding surfaces.

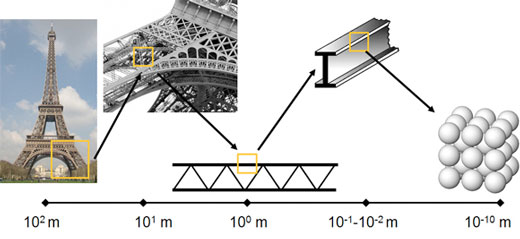

Many natural and man-made materials exhibit structures on more than one length scale; in some materials, the structural elements themselves have structure. This structural hierarchy can play a major part in determining the bulk material properties.

Hierarchical structures are very common in nature; but only recently have they been systematically studied in materials science, in order to understand the specific effects they can have on the mechanical properties of various systems.

Take animals that cling to walls and walk on ceilings. As we have seen before, they owe this ability to micro- and nanoscale attachment elements.

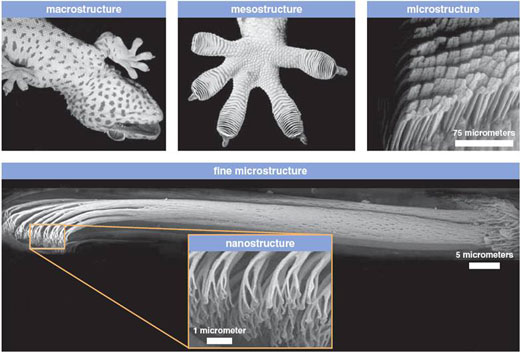

The highest adhesion forces in the animal kingdom are encountered in geckos; they have evolved one of the most versatile and effective dry adhesives known to man. A gecko is the heaviest animal that can ëstandí on a ceiling, with its feet over its head. This is why scientists are intensely researching the adhesive system of the tiny hairs on its feet.

The gecko paw's hierarchical structure – its branches become increasingly smaller over three levels – has attracted much research interest.

Nevertheless, to illustrate how ingenious Nature's design is, researchers haven't yet managed to come up with a simple recipe for fabricating synthetic gecko adhesives.

In 2000, scientists discovered (PNAS, "Evidence for van der Waals adhesion in gecko setae") that van der Waalsí interactions were the main contributors to gecko adhesion force: the nanostructures at the end of the gecko's hairs interact at the atomic level with molecules on the surface the gecko is trying to grip. This interaction, powered by van der Waals forces, causes the geckoís toes to easily attach and detach as needed.

Since then, many research groups around the world have spent considerable effort in trying to fabricate synthetic gecko adhesives, i.e. artificial materials that reproduce its peculiar properties of adhesion and friction.

Understanding the effects of hierarchical structure and how they influence macroscopic mechanical properties (such as friction) can guide the synthesis of new materials with physical properties, which are tailored for specific applications.

This means that structural hierarchy can provide a way to tune and optimize the tribological properties of a surface. Experimental results by U.S. scientists indicate that by exploiting hierarchical structure, the global friction properties of a surface can be tuned arbitrarily. To achieve this, it is essential to provide structuring at various different length scales (see: Static and dynamic friction of hierarchical surfaces).

Science notes: Smart materials with tunable friction

Key takeaways

• Researchers are working on a new class of 'smart' materials with the ability to modulate the friction of a surface.

• There are several approaches, quite different from each other, to fabricate these smart materials.

• The hierarchical structure of materials affects their mechanical properties. Understanding how they influence macroscopic mechanical properties (such as friction) can guide the synthesis of new materials with physical properties, which are tailored for specific applications.

Vocabulary

• Smart material: A functional material that can reversibly respond to changes in its environment via external stimuli such as temperature, light, pressure or electricity.

• Photochromic molecules: Molecules whose properties can be changed reversibly under the action of light as an external stimulus.

• Hydrogels: Swollen polymer networks, class of materials closely resembling biological tissues in their physical and chemical properties.

• Hierarchical materials: Materials that exhibit structures on more than one length scale.

– End –

Posted: November 2019.

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC