Buckypaper: Nanotechnology Definition, Uses, Properties

Definition: Buckypaper is a thin sheet material made from an aggregate of carbon nanotubes (CNTs) or fullerenes. Renowned for its exceptional strength and electrical conductivity, buckypaper represents a significant advancement in the field of materials science, offering a wide range of potential applications from aerospace to electronics and beyond. This glossary article delves into the key aspects of buckypaper, including its composition, production, properties, and applications.

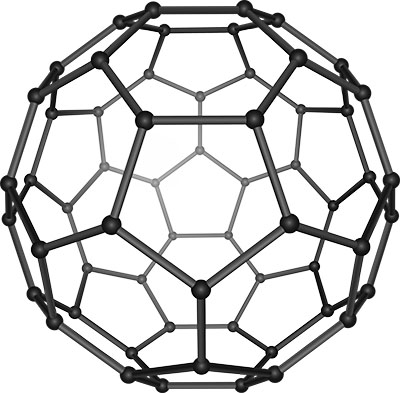

Buckypaper is named after buckminsterfullerene, a form of carbon that resembles the geodesic domes designed by architect Buckminster Fuller. These domes are characterized by their spherical shape made up of interlocking hexagonal and pentagonal facets, similar to the structure of a carbon molecule known as C60 or a "buckyball."

The term "bucky" in buckypaper directly refers to this resemblance, highlighting the material's foundational composition of carbon nanotubes or fullerenes that share the geometric patterns observed in Fuller's architectural work. The naming convention celebrates the unique molecular configuration of carbon atoms in these nanostructures, which is critical to the remarkable properties of buckypaper, such as its strength, electrical conductivity, and thermal conductivity.

Composition and Production of Buckypaper

Buckypaper is primarily composed of carbon nanotubes, which are cylindrical molecules consisting of rolled-up sheets of single-layer carbon atoms (graphene). These nanotubes can be single-walled (SWCNTs) or multi-walled (MWCNTs), depending on the application requirements.

The production of buckypaper involves dispersing carbon nanotubes in a solvent to create a uniform suspension. This suspension is then filtered through a membrane, capturing the CNTs on the surface as the solvent passes through. The resulting mat of CNTs is dried, forming a thin, flexible, and cohesive sheet known as buckypaper.

Properties of Buckypaper

- Strength: Buckypaper is noted for its remarkable strength-to-weight ratio, being significantly stronger and lighter than conventional materials such as steel.

- Electrical Conductivity: It exhibits excellent electrical conductivity, which can be tailored by adjusting the type, purity, and alignment of the carbon nanotubes within the paper.

- Thermal Conductivity: Along with its electrical properties, buckypaper also demonstrates superior thermal conductivity, making it an ideal material for heat dissipation applications.

- Flexibility: Despite its strength, buckypaper is highly flexible, allowing it to be molded into various shapes or applied to different surfaces.

Applications of Buckypaper

Buckypaper, a thin sheet made from an aggregate of carbon nanotubes or fullerenes, finds its uniqueness not just in its composition but also in its wide range of applications. Its preference over individual carbon nanotubes (CNTs) or fullerenes in certain scenarios stems from its distinct properties and form factor. Below, we explore specific applications and elucidate why buckypaper is the material of choice in these contexts.

- Aerospace Engineering: In aerospace, weight reduction without compromising strength is paramount. Buckypaper's high strength-to-weight ratio makes it an ideal candidate for manufacturing parts of aircraft and spacecraft. Unlike individual CNTs, which are challenging to incorporate into composite materials due to dispersion and alignment issues, buckypaper can be easily layered into composites, enhancing their mechanical properties while maintaining lightweight characteristics.

- Electromagnetic Interference (EMI) Shielding: Buckypaper is highly effective in EMI shielding due to its excellent electrical conductivity. When compared to fullerenes or individual CNTs, buckypaper provides a more uniform and scalable solution that can be easily integrated into electronic devices. Its thin, flexible nature allows for application in a wide range of device sizes and shapes, offering protection without significant weight or space penalties.

- Energy Storage: In energy storage devices, buckypaper serves as an excellent electrode material for batteries and supercapacitors. Its high surface area and conductive properties, derived from the densely packed CNT network, enable higher energy density and faster charge/discharge rates than what might be achieved with fullerenes or individual CNTs alone. The cohesive structure of buckypaper facilitates efficient electron transport and ion diffusion across the electrode, leading to improved performance in energy storage applications.

- Environmental Filtration: Buckypaper's porosity and chemical stability make it an outstanding material for filtering water and air pollutants. The interconnected network of carbon nanotubes in buckypaper provides a large surface area for adsorbing contaminants, surpassing the efficiency of loose fullerenes or CNTs. Additionally, buckypaper can be tailored to target specific pollutants by functionalizing the CNTs, offering a versatility that is difficult to achieve with other carbon nanostructures.

- Thermal Management: Due to its high thermal conductivity, buckypaper is used in thermal management systems to dissipate heat in electronic devices. Its ability to evenly spread heat across its surface and into the ambient environment helps prevent hotspots, ensuring the longevity and reliability of electronic components. The cohesive, flexible sheet form of buckypaper is easier to handle and integrate into devices than individual CNTs or fullerenes, providing a practical solution for manufacturers.

In summary, the preference for buckypaper over individual CNTs or fullerenes in these applications is largely due to its unique physical form, which combines the advantageous properties of carbon nanomaterials into a manageable, versatile, and highly functional material. Its ability to offer strength, conductivity, and thermal management in a lightweight, flexible form makes it an indispensable material in advancing technology and engineering fields.

Further Reading

Engineering with Computers, Unfolding the mechanical properties of buckypaper composites: nano- to macro-scale coupled atomistic-continuum simulations

Composites Part B: Engineering, Buckypaper and its composites for aeronautic applications