Nanoporous Materials: Unlocking New Possibilities in Diverse Applications

What are Nanoporous Materials?

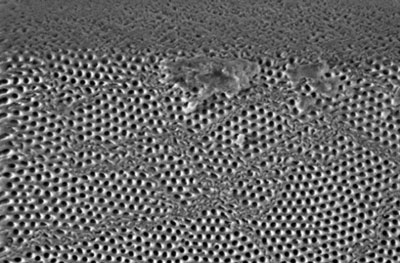

Nanoporous materials are a class of materials characterized by the presence of pores or cavities with sizes in the nanometer range, typically less than 100 nm. These materials have an exceptionally high surface area to volume ratio and exhibit unique properties that make them attractive for a wide range of applications, from energy storage and conversion to drug delivery and environmental remediation.

Classification of Nanoporous Materials

Nanoporous materials can be classified based on their pore size, pore geometry, and chemical composition. The International Union of Pure and Applied Chemistry (IUPAC) defines three categories of nanoporous materials:

- Microporous Materials: Pore sizes less than 2 nm

- Mesoporous Materials: Pore sizes between 2 nm and 50 nm

- Macroporous Materials: Pore sizes greater than 50 nm

In terms of pore geometry, nanoporous materials can have various structures, such as ordered or disordered pore arrangements, interconnected or isolated pores, and uniform or hierarchical pore size distributions. The chemical composition of nanoporous materials can also vary widely, including inorganic, organic, and hybrid materials.

Synthesis of Nanoporous Materials

Several methods have been developed for the synthesis of nanoporous materials, each with its own advantages and limitations. Some common synthesis techniques include:

Template-Based Synthesis

Template-based synthesis involves the use of a sacrificial template, such as surfactants, block copolymers, or nanoparticles, to guide the formation of the nanoporous structure. The template is removed after the synthesis, leaving behind a well-defined porous network. This method allows for precise control over pore size, shape, and ordering.

Sol-Gel Processing

Sol-gel processing is a versatile method for synthesizing nanoporous materials, particularly oxide-based materials. It involves the hydrolysis and condensation of precursor molecules to form a sol, which then undergoes gelation and drying to yield a nanoporous solid. The pore size and structure can be tuned by adjusting the processing conditions and precursor chemistry.

Electrochemical Etching

Electrochemical etching is a top-down approach for creating nanoporous structures in semiconductors and metals. It involves the selective dissolution of the material in an electrolyte solution under an applied potential. By controlling the etching conditions, such as the electrolyte composition, applied potential, and etching time, nanoporous structures with desired pore sizes and morphologies can be obtained.

Properties and Applications of Nanoporous Materials

Nanoporous materials exhibit a range of unique properties that make them attractive for various applications:

High Surface Area

The presence of nanopores leads to an exceptionally high surface area to volume ratio in nanoporous materials. This high surface area is beneficial for applications that involve surface-driven processes, such as catalysis, adsorption, and sensing. The increased surface area provides more active sites for chemical reactions, enhanced adsorption capacity for molecules, and improved sensitivity for detecting target analytes.

Tunable Pore Size and Chemistry

The ability to control the pore size and surface chemistry of nanoporous materials allows for the tailoring of their properties for specific applications. By adjusting the pore size, nanoporous materials can be designed to selectively adsorb or filter molecules based on their size, enabling applications in separation and purification processes. The surface chemistry can also be modified to introduce specific functional groups or to enhance the interaction with target molecules.

Confinement Effects

The nanoscale confinement of molecules within the pores of nanoporous materials can lead to unique properties and behavior. Confinement effects can alter the thermodynamics and kinetics of chemical reactions, leading to enhanced reactivity, selectivity, and stability. These effects are exploited in applications such as catalysis, energy storage, and drug delivery, where the confinement of molecules within nanopores can improve the performance and efficiency of the materials.

Some specific applications of nanoporous materials include:

- Energy Storage and Conversion: Nanoporous materials are used in batteries, supercapacitors, and fuel cells as electrode materials and electrolyte scaffolds. The high surface area and nanoscale confinement effects enhance the charge storage capacity and ion transport properties.

- Catalysis: Nanoporous materials are employed as catalysts and catalyst supports due to their high surface area, tunable pore size, and ability to confine reactants. They can improve catalytic activity, selectivity, and stability in various chemical reactions.

- Environmental Remediation: Nanoporous materials are used for the adsorption and removal of pollutants, such as heavy metals, organic contaminants, and greenhouse gases, from water and air. Their high adsorption capacity and selectivity make them effective for environmental cleanup.

- Drug Delivery: Nanoporous materials can serve as carriers for controlled drug delivery. The porous structure allows for the loading and release of drug molecules, while the pore size and surface chemistry can be tailored to achieve targeted delivery and controlled release kinetics.

Challenges and Future Perspectives

Despite the significant progress in the development and application of nanoporous materials, several challenges remain. One of the main challenges is the scalability and cost-effective production of high-quality nanoporous materials. Many synthesis methods are currently limited to small-scale production, and the development of large-scale manufacturing processes is crucial for their widespread adoption.

Another challenge is the long-term stability and durability of nanoporous materials under operating conditions. The high surface area and nanoscale features can make these materials susceptible to degradation, fouling, and structural changes over time. Strategies for improving the stability and lifetime of nanoporous materials are actively being investigated.

Future research in nanoporous materials will focus on the development of novel synthesis techniques, the exploration of new material compositions, and the integration of nanoporous materials with other functional materials and devices. The combination of experimental and computational approaches will aid in the rational design and optimization of nanoporous materials for specific applications. Additionally, the investigation of nanoporous materials for emerging applications, such as energy harvesting, sensing, and biomedical devices, will open up new opportunities and drive further advancements in this field.

Further Reading

Annual Review of Chemical and Biomolecular Engineering, Characterization of Nanoporous Materials