Plastic Electronics: Flexible and Lightweight Solutions for the Future

What are Plastic Electronics?

Plastic electronics, also known as organic electronics or printed electronics, is a field that utilizes conductive polymers or small organic molecules to create electronic devices and circuits. Unlike traditional electronics that rely on rigid, inorganic semiconductors like silicon, plastic electronics leverage the unique properties of organic materials to develop flexible, lightweight, and cost-effective electronic components.

Key Concepts in Plastic Electronics

Plastic electronics revolves around several key concepts that distinguish it from conventional electronics:

- Organic Semiconductors: Plastic electronics relies on organic semiconductors, which are carbon-based materials that exhibit electrical conductivity and semiconducting properties. These materials include conductive polymers, such as polyaniline and polythiophene, and small organic molecules, like pentacene and rubrene.

- Solution Processability: One of the main advantages of plastic electronics is the ability to process organic materials using solution-based techniques. This allows for the fabrication of electronic devices using methods like printing, coating, and roll-to-roll processing, which are more cost-effective and scalable compared to traditional semiconductor manufacturing.

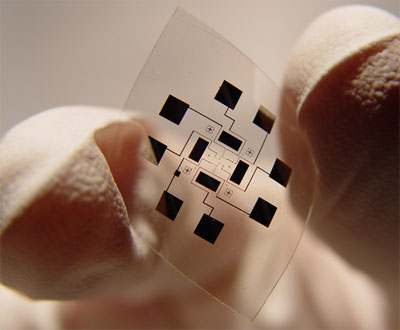

- Flexibility and Stretchability: Organic semiconductors can be deposited on flexible substrates, such as plastic films or even paper, enabling the development of bendable, stretchable, and conformable electronic devices. This flexibility opens up new possibilities for applications in wearable technology, flexible displays, and smart packaging.

Types of Plastic Electronic Devices

Plastic electronics encompasses a wide range of devices and applications, including:

Organic Light-Emitting Diodes (OLEDs)

OLEDs are a type of display technology that uses organic semiconductors to emit light. They offer several advantages over traditional liquid crystal displays (LCDs), such as wider viewing angles, higher contrast ratios, and faster response times. OLEDs are widely used in smartphones, televisions, and digital signage.

Organic Photovoltaics (OPVs)

OPVs are solar cells that use organic semiconductors to convert sunlight into electricity. While their power conversion efficiencies are currently lower than those of inorganic solar cells, OPVs offer the benefits of flexibility, lightweight, and low-cost manufacturing. They have potential applications in building-integrated photovoltaics, portable power sources, and smart textiles.

Organic Field-Effect Transistors (OFETs)

OFETs are transistors that use organic semiconductors as the active layer. They are the building blocks of organic integrated circuits and can be used to create logic gates, memory devices, and sensors. OFETs have the advantage of being compatible with flexible substrates and can be fabricated using solution-based processing techniques.

Advantages of Plastic Electronics

Plastic electronics offers several advantages over conventional electronics:

- Flexibility and Stretchability: Plastic electronic devices can be bent, rolled, and stretched without losing their functionality, enabling the development of flexible displays, wearable sensors, and conformable electronic skin.

- Lightweight and Thin: Organic materials used in plastic electronics are typically lighter and thinner than their inorganic counterparts, making them suitable for applications where weight and form factor are critical, such as in aerospace and automotive industries.

- Cost-Effective Manufacturing: Solution-based processing techniques used in plastic electronics, such as printing and coating, are generally more cost-effective and scalable compared to traditional semiconductor manufacturing methods. This can lead to lower production costs and faster time-to-market for plastic electronic devices.

- Tunable Properties: The properties of organic semiconductors can be tuned through chemical synthesis and molecular engineering, allowing for the optimization of device performance and the development of new functionalities.

Challenges and Future Perspectives

Despite the numerous advantages of plastic electronics, there are still challenges that need to be addressed for their widespread adoption. One of the main challenges is the relatively lower performance of organic semiconductors compared to their inorganic counterparts. Organic materials typically have lower charge carrier mobilities and stability, which can limit their use in high-performance applications.

Future research in plastic electronics will focus on developing new organic materials with improved electrical properties, stability, and processability. The integration of plastic electronics with other emerging technologies, such as the Internet of Things (IoT) and 5G networks, will create new opportunities for smart and connected devices. Additionally, the exploration of hybrid systems that combine organic and inorganic materials can lead to the development of high-performance, flexible electronic devices with the best of both worlds.

Further Reading

Nao Convergence, High-performance printed electronics based on inorganic semiconducting nano to chip scale structures

Progress in Materials Science, 3D printed electronics: Processes, materials and future trends