| Posted: Aug 28, 2014 |

World-first demonstration of pilot-scale boron nitride nanotube production

|

|

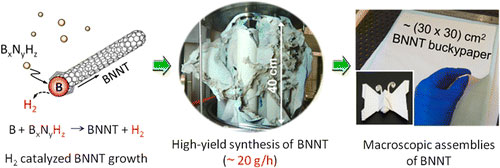

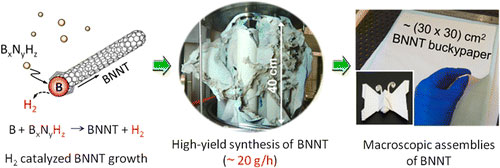

(Nanowerk News) With the breakthrough demonstration of the world’s first pilot-scale production of boron nitride nanotubes, the National Research Council of Canada (NRC) has unlocked an advanced material to drive high-value manufacturing in Canada ("Hydrogen-Catalyzed, Pilot-Scale Production of Small-Diameter Boron Nitride Nanotubes and Their Macroscopic Assemblies").

|

|

The National Research Council’s first target for boron nitride nanotubes (BNNT) is to integrate them into advanced engineered materials for defence and security applications such as light-weight ceramic and transparent armour for vehicles and personal protection. Boron nitride nanotubes have unique structural, electronic and optical properties. When integrated into composite materials and systems, these nanotubes enable entirely new classes of material performance across many industrial applications.

|

|

With this major advance, Canada now has the largest boron nitride nanotube production capacity in the world, and a production rate 100 times faster than any earlier technologies. Applications and product development previously limited by low production volumes can now be expected to grow rapidly.

|

|

|

Quick Facts

|

|

Other applications may include: transparent materials and ceramic parts for the aerospace sector; metallic and polymer composites for the automotive sector; sensors and other structural or multifunctional applications for the aerospace and energy sectors; fire retardant materials for the construction sector; and cancer and cellular regeneration therapies for the health sector.

|

|

Boron nitride nanotubes have a structure very similar to carbon nanotubes. They share the extraordinary mechanical properties and thermal conductivity of carbon nanotubes, but have the added advantages of optical and infrared transparency, greater thermal and chemical stability, neutron shielding, electrical insulation, and the ability to generate electrical current when subjected to mechanical stress.

|

|

NRC’s new process uses specialized equipment manufactured by Tekna Plasma Systems Inc., a Canadian company and a world leader in the development, design and construction of integrated plasma systems for nanoparticle synthesis and in the supply of high quality micropowders and nanopowders.

|

|

This nanotube work is part of NRC’s Security Materials Technology program, a joint initiative between NRC, Canadian defence industry partners, and Defence R&D Canada (DRDC). The program will strengthen the global competitiveness of the Canadian armour industry while simultaneously providing world-class built-in-Canada gear to the Canadian Forces, police and first responders.

|