| Posted: Jan 20, 2016 |

Sub-5 nanometer gaps provide a golden opportunity

(Nanowerk News) Lining up gold nanoparticles in narrow trenches carved into a gold substrate has enabled A*STAR researchers to greatly enhance an optical effect that doubles the frequency of impinging light ("Second-Harmonic Generation from Sub-5 nm Gaps by Directed Self-Assembly of Nanoparticles onto Template-Stripped Gold Substrates"). This approach could help produce miniature ‘on-chip’ devices that convert the frequency of light.

|

|

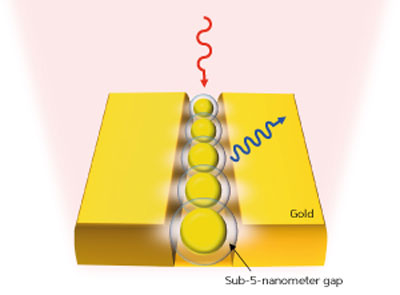

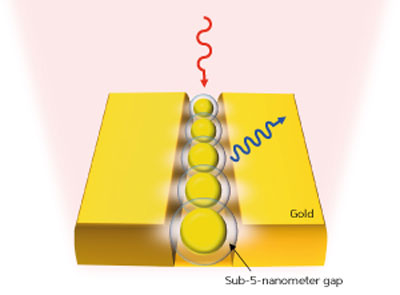

| Tiny gaps between gold nanoparticles in a trench and the gold substrate greatly enhance frequency doubling of incident light.

|

|

Nanoparticles of metals, such as gold, act as miniature antennas for light, concentrating the electromagnetic field of incident light. This field intensification could be exploited to boost nonlinear optical effects, which occur only in very strong fields.

|

|

One such nonlinear effect is second-harmonic generation (SHG), in which two incoming photons with the same frequency combine to form one photon with twice the frequency. Symmetry considerations, however, preclude SHG from occurring inside a gold structure; it can only occur on a gold surface. This limitation has previously hindered the use of gold nanoparticles for SHG.

|

|

Now, Joel Yang and Zhaogang Dong of the A*STAR Institute of Materials Research and Engineering and co-workers have solved this problem by producing gold structures in which approximately 8-nanometer-diameter gold nanoparticles coated with an organic compound are squeezed into 12-nanometer-wide trenches. This creates gaps about two nanometers wide on either side of the nanoparticles (see image). These tiny gaps have a dual function — both boosting the field enhancement of the nanoparticles and increasing the interaction of light with the gold surface.

|

|

The enhancement is stunning. The combination of these two effects augments SHG by more than 4,000 times compared to when the same gold nanoparticles are packed on to a flat gold substrate. “This enhancement in SHG is one of the highest ever reported,” notes Yang.

|

|

The team produce the structures in two stages; they used a ‘top-down’ lithography process to create the trenches and then ‘bottom-up’ self-assembly to drop the nanoparticles into the trenches. Importantly, both processes are scalable, so that the structures could potentially be manufactured on a commercially viable scale.

|

|

While conventional nonlinear crystals that perform SHG in their interiors still have higher conversion efficiencies, the tiny size of the nanostructures makes them very attractive for realizing SHG on very small scales, including devices that can be integrated into chips. Yang notes that there is much scope for optimization. “There’s plenty of room for improvement, especially for achieving SHG in a miniaturized format,” he says.

|

|

The researchers are exploring the use of other materials to achieve even higher SHG enhancements. They are also liaising with a Singapore-based company with a view to commercializing the technique in the future.

|