| Posted: Oct 22, 2017 |

On-demand 3D-printing of plasmonic nanostructures

(Nanowerk News) Structures built on the scale of nanometers could build new and improved light sources, sensors and computers. Scientists created a novel way to 3-D print on virtually any material or shape without costly and time-consuming masking steps (ACS Applied Materials & Interfaces, "Direct-write 3D nanoprinting of plasmonic structures").

|

|

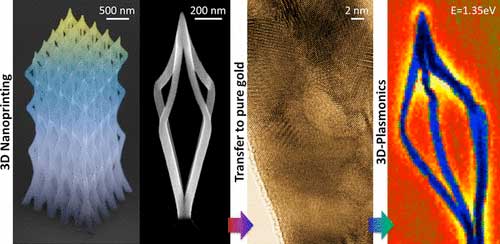

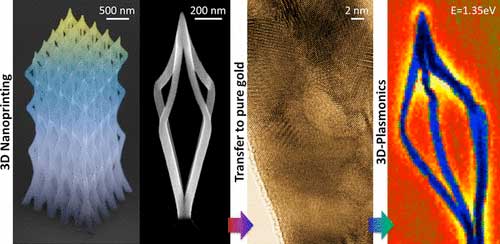

| Focused electron beams are used to convert surface-bound molecules made from gold and carbon into the gas phase and deposit them to construct precise 3-D freestanding structures of pure gold. The ultra-sharp features produce free electron oscillations, or quasiparticles called plasmons, with high efficiency. (© ACS)

|

|

In a patterned sequence, researchers used a focused electron beam to dissociate surface-bound carbon- and metal-containing molecules and deposit them with precision. The result is a 3-D gold-carbon shape (shown here in a style reminiscent of Gandalf’s staff). They purified these structures in situ (inside the growth reactor) to remove carbon. They tested the resulting freestanding pure-gold architectures for plasmonic behavior—tiny, rapid waves of electron density created when light hits metal.

|

|

The 3-D printing approach produces customized, from the bottom up, nanostructures on demand. The technology paves the way to maskless fabrication of custom 1-, 2-, and 3-D architectures on virtually any material and surface shape. The materials can have specific plasmonic behaviors. Plasmonic oscillations encode more data than possible with conventional technologies. Thus, this advance may speed the advent of novel light sources, sensor devices and ultra-dense information storage technologies.

|

|

Structures on the scale of nanometers—much smaller than wavelengths of light—may improve transmission of plasmons, or small waves of electron density created when light hits an electron conductor, such as a metal.

|

|

To 3-D print nanoscale shapes with controlled properties, researchers integrated design, simulation and experiment. They used pattern sequencing to guide focused electron beams in inducing deposition of organometallic precursor molecules on a surface. Then, they removed residual carbon via in situ purification with water vapor to produce purely metallic freestanding 3-D nanostructures—an advance over previous 2-D nanoprinting with materials that contained significant carbon in addition to the desired metal. The structure that was produced—akin to the outline of up- and down-facing pyramids connected at their bases—demonstrated high plasmonic resonance at branches and tips.

|

|

On-demand 3-D printing can take place on virtually any material and surface shape, pushing nanoscale optical, mechanical, magnetic and even multifunctional materials beyond current limits and paving the way to functional plasmonic architectures for next-generation photonic, photovoltaic and data-storage technologies.

|