| Apr 03, 2020 | |

Capturing 3D microstructures in real time(Nanowerk News) Modern scientific research on materials relies heavily on exploring their behavior at the atomic and molecular scales. For that reason, scientists are constantly on the hunt for new and improved methods for data gathering and analysis of materials at those scales. |

|

| Researchers at the Center for Nanoscale Materials (CNM), a U.S. Department of Energy (DOE) Office of Science User Facility located at the DOE’s Argonne National Laboratory, have invented a machine-learning based algorithm for quantitatively characterizing, in three dimensions, materials with features as small as nanometers. Researchers can apply this pivotal discovery to the analysis of most structural materials of interest to industry. | |

| “What makes our algorithm unique is that if you start with a material for which you know essentially nothing about the microstructure, it will, within seconds, tell the user the exact microstructure in all three dimensions,” said Subramanian Sankaranarayanan, group leader of the CNM theory and modeling group and an associate professor in the Department of Mechanical and Industrial Engineering at the University of Illinois at Chicago. | |

| “For example, with data analyzed by our 3D tool,” said Henry Chan, CNM postdoctoral researcher and lead author of the study (npj Computational Materials, "Machine learning enabled autonomous microstructural characterization in 3D samples"), “users can detect faults and cracks and potentially predict the lifetimes under different stresses and strains for all kinds of structural materials.” | |

|

|

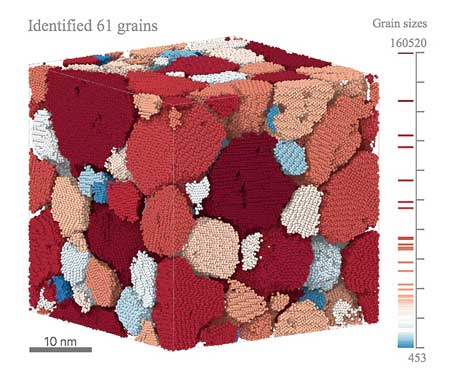

| Machine-learning enabled characterization of 3D microstructure showing grains of different sizes and their boundaries. (Image: Argonne National Laboratory) | |

| Most structural materials are polycrystalline, meaning a sample used for purposes of analysis can contain millions of grains. The size and distribution of those grains and the voids within a sample are critical microstructural features that affect important physical, mechanical, optical, chemical and thermal properties. Such knowledge is important, for example, to the discovery of new materials with desired properties, such as stronger and harder machine components that last longer. | |

| In the past, scientists have visualized 3D microstructural features within a material by taking snapshots at the microscale of many 2D slices, processing the individual slices, and then pasting them together to form a 3D picture. Such is the case, for example, with the computerized tomography scanning routine done in hospitals. That process, however, is inefficient and leads to the loss of information. Researchers have thus been searching for better methods for 3D analyses. | |

| “At first,” said Mathew Cherukara, an assistant scientist at CNM, “we thought of designing an intercept-based algorithm to search for all the boundaries among the numerous grains in the sample until mapping the entire microstructure in all three dimensions, but as you can imagine, with millions of grains, that is extraordinarily time-consuming and inefficient.” | |

| “The beauty of our machine learning algorithm is that it uses an unsupervised algorithm to handle the boundary problem and produce highly accurate results with high efficiency,” said Chan. “Coupled with down-sampling techniques, it only takes seconds to process large 3D samples and obtain precise microstructural information that is robust and resilient to noise.” | |

| The team successfully tested the algorithm by comparison with data obtained from analyses of several different metals (aluminum, iron, silicon and titanium) and soft materials (polymers and micelles). These data came from earlier published experiments as well as computer simulations run at two DOE Office of Science User Facilities, the Argonne Leadership Computing Facility and the National Energy Research Scientific Computing Center. Also used in this research were the Laboratory Computing Resource Center at Argonne and the Carbon Cluster in CNM. | |

| “For researchers using our tool, the main advantage is not just the impressive 3D image generated but, more importantly, the detailed characterization data,” said Sankaranarayanan. “They can even quantitatively and visually track the evolution of a microstructure as it changes in real time.” | |

| The machine-learning algorithm is not restricted to solids. The team has extended it to include characterization of the distribution of molecular clusters in fluids with important energy, chemical and biological applications. | |

| This machine-learning tool should prove especially impactful for future real-time analysis of data obtained from large materials characterization facilities, such as the Advanced Photon Source, another DOE Office of Science User Facility at Argonne, and other synchrotrons around the world. |

| Source: Argonne National Laboratory | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |