| Aug 04, 2020 | |

Machine learning probes 3D microstructures(Nanowerk News) Materials science explores how materials behave, including at the atomic and molecular scales. Researchers are constantly looking for improved ways to gather and analyze data on these scales. |

|

| Scientists at the Center for Nanoscale Materials have developed a machine learning technique for materials research (Nature Computational Materials, "Machine learning enabled autonomous microstructural characterization in 3D samples"). | |

| Machine learning is a form of artificial intelligence in which an algorithm improves itself as it works with more and more data. The technique visualizes and quantifies the atomic and molecular structures in three-dimensional samples in real time. | |

| This machine learning technique can quickly identify, track, and quantify complex structures in materials. These atomic- and molecular-scale “microstructures” include features such as grain size and pores. These features affect how materials perform. | |

| The new technique should be especially useful for analyzing data in real time. Researchers obtain these data from large materials characterization facilities such as electron microscopes and synchrotrons. The technique will also help researchers analyze 3D data on how atoms in materials are arranged. | |

|

|

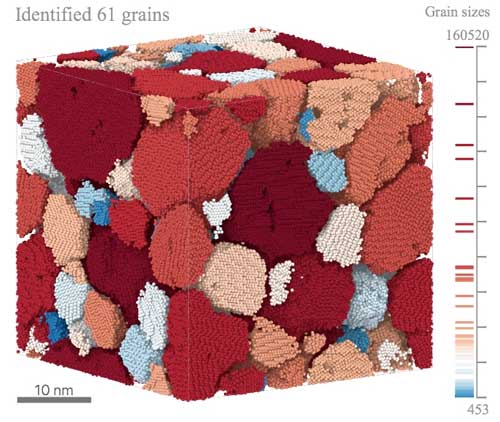

| Machine-learning enabled characterization of a 3D microstructure. This snapshot is from a 2-million molecule simulation of polycrystalline ice. The image shows ice grains and their boundaries. (Image: Argonne National Laboratory) | |

| The ability to characterize the microstructural and nanoscale features in 3D samples of materials is important for many applications. These features include grain size distributions in metals, the voids and porosity in solid porous materials, and the structures that appear during self- and directed-assembly of soft matter. | |

| Scientists at the Center for Nanoscale Materials, a Department of Energy (DOE) Office of Science user facility, have developed an unsupervised machine learning-based technique for identifying and characterizing microstructures in 3D samples. | |

| This technique also combines topology (or shape) classification, image processing, and clustering algorithms. When coupled with methods to reduce sample size, the technique requires only seconds to process large 3D samples and obtain precise microstructure information. It is not sensitive to the presence of structures that stymie standard classification methods. | |

| The team successfully tested the technique by comparing data obtained from analyses of several different metals (aluminum, iron, silicon, and titanium) and soft materials (polymers and micelles). These data came from earlier published experiments as well as computer simulations run at two DOE Office of Science user facilities, the Argonne Leadership Computing Facility and the National Energy Research Scientific Computing Center. | |

| The machine-learning technique is not restricted to solids. The team has extended it to include characterization of the distribution of molecular clusters in fluids with important energy, chemical, and biological applications. |

| Source: Center for Nanoscale Materials, Argonne National Laboratory | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |