| Jul 21, 2021 |

Printing strategies for scaling up perovskite solar cells

(Nanowerk News) To reach the target of carbon neutrality, a transition from fossil energy to renewable energy generation is indispensable. Photovoltaic technology is considered as one of the most prominent sources of renewable energy.

|

|

For decades, about 90% of global solar cell market has been dominated by silicon solar cells. Although the price of silicon solar panels decreases year by year, it is a big challenge to significantly reduce its manufacturing cost further. Hence, next-generation photovoltaic technologies are in urgent need of new materials and novel techniques.

|

|

Recently, metal halide perovskite solar cells (PSCs) have attracted extensive attention from both academia and industry, due to their excellent photoelectric conversion efficiency and great commercial potential.

|

|

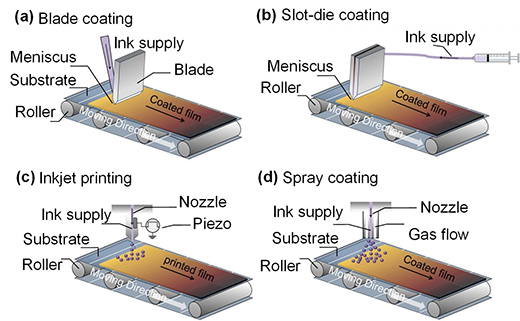

| Scalable methods for PSCs deposition: (a) blade-coating, (b) slot-die-coating, (c) inkjet printing, and (d) spray-coating. (Image: Science China Press)

|

|

Metal halide perovskite materials can be easily synthesized in solution at low-temperature and deposited into thin-film through a variety of printing methods.

|

|

Recently, many reviews have been published on the topic of perovskite film deposition techniques and mechanisms, such as solvent engineering and additives-engineering, whereas discussions about ink engineering for printing high-quality perovskite films as well as other function layers are few.

|

|

In this article (National Science Review, "Printing strategies for scaling-up perovskite solar cells"), the authors provide a systematical overview of applicable printing technologies that can be possibly used for scaling-up PSCs.

|

|

The authors consider that ink engineering is the key issue to achieve high quality thin-films for efficient solar cells. Therefore, they mainly focus on the perspective of perovskite precursor ink formula and additives on controlling the film formation process. They analyze the potential physical and chemical mechanisms of the nucleation and crystallization process during the printing. For the additives in the printing of PSCs, the authors discuss the effect of additives for the film formation process, the microstructure and defect population.

|

![Schematic illustration of in-line R2R processing of all perovskite solar cells layers]() |

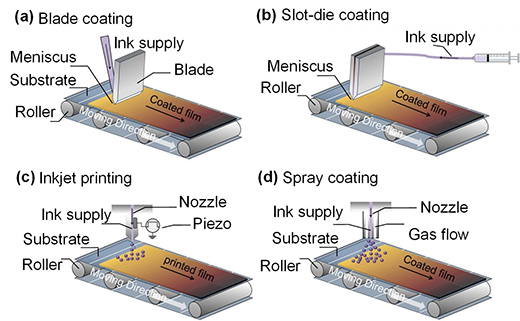

| Schematic illustration of in-line R2R processing of all PSC layers. (Image: Science China Press)

|

|

Moreover, they also present the technical feasibility of printing the other layers besides perovskite layers, including hole transporting layers (HTL) and electron transporting layers (ETL), which might enable a rapid and mass production of PSCs.

|

|

Finally, they introduce the recent progress of roll-to-roll (R2R) printing and the stability issues of perovskite modules, and give a prospect of mass production of perovskite solar modules in the near future.

|