| Aug 04, 2021 |

Incorporating graphene in polymer nanolaminates paves the way for the development of effective electromagnetic interference shields

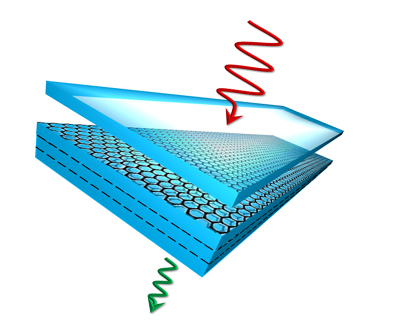

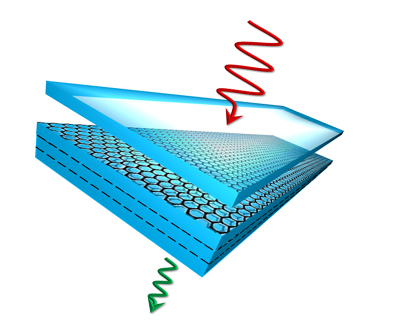

(Nanowerk News) The incorporation of centimetre-size monolayer graphene in polymer nanolaminates, paving the way for the development of effective electromagnetic interference (EMI) shields, has been published in Nature Communications ("Effective EMI shielding behaviour of thin graphene/PMMA nanolaminates in the THz range").

|

|

Since its isolation in 2004 by Geim and Novoselov from the University of Manchester (Nobel Prize in Physics in 2010), graphene has been termed as a ‘wonder material’ due to its exceptional properties that have already been exploited in many applications and products. However, the use of graphene in a form of tiny flakes in polymer composites limits the full exploitation of the excellent properties of graphene, thus requiring high filler loadings for achieving satisfactory electrical and mechanical properties.

|

|

A team of researchers from the Institute of Chemical Engineering Sciences of Foundation for Research and Technology-Hellas (FORTH/ ICE-HT), the Department of Chemical Engineering of the University of Patras, and the Department of Physics of the University of Napoli Federico II, led by Professor Costas Galiotis, had the innovative ideato use centimetre-size graphene sheets as reinforcement in polymer composites with a nanolaminate architecture.

|

|

This has been demonstrated to be a smart strategy to overcome the typical drawbacks of nanoparticle fillers, thanks to the large lateral size which ensures efficient stress transfer, and uniform and controllable dispersion through the alternation of the polymer and graphene layers. Large-size monolayer graphene was produced by the technique of chemical vapor deposition (CVD): it has a monoatomic thickness and, unlike small flakes, there are no size limitations in the other dimensions (length and width).

|

|

| Sketch of the CVD graphene/polymer nanolaminates for EMI shielding. (Image: FORTH)

|

|

The centimetre-scale CVD graphene/ polymer nanolaminates were then produced with a semi-automatic process that allows for the manipulation of ultra-thin film, and have been found to outperform, for the same graphene content, state-of-the-art flake-based graphene polymer composites in terms of mechanical reinforcement and electrical properties.

|

|

Most importantly these thin laminate materials show a very high electromagnetic interference (EMI) shielding effectiveness in the Terahertz range, reaching 60 dB for a small thickness of 33 µm, and an absolute EMI shielding effectiveness per unit weight and thickness which is amongst the highest values for synthetic, non-metallic materials produced to date.

|

|

Prof. Galiotis has stated: “In this paper we have tried to exploit the excellent mechanical and electrical properties of monolayer graphene when used as a reinforcement of engineering polymers. So far by the use of short graphene flakes this was not possible due to the small size of the inclusions. Recent developments in the production of continuous (large size) monolayer graphene membranes allowed us to fabricate nanolaminates that incorporated tens and even hundreds of graphene layers embedded into commercial polymers. This has led to graphene nanolaminates with stiffnesses approaching those of perfect graphene per volume fraction and effective EMI shielding performance. This work paves the way for the development of nanolaminates with exceptional properties for aerospace, automotive but also a number of electronic applications.”

|