| Sep 23, 2021 |

Nano-precision metrology of X-ray mirrors

(Nanowerk News) A new laser speckle angular measurement (SAM) technique detailed in a paper in Light: Science and Applications, published today demonstrates how slope error measurements can be reduced dramatically. This is important because X-ray mirrors are widely used for synchrotron radiation facilities, X-ray free-electron lasers and astronomical X-ray telescopes. However, short wavelength and grazing incidence impose strict limits on the permissible slope errors.

|

|

Although, advanced polishing techniques have produced mirrors with slope errors (below 50nrad root mean square (rms)), many existing metrology techniques struggle to measure them. Additionally, SAM is compact, low-cost and integrates with most existing X-ray mirror metrology instruments.

|

|

The paper "Nano-precision metrology of X-ray mirrors with laser speckle angular measurement" by Dr. Hongchang Wang, Simone Moriconi and Prof. Kawal Sawhney from the Optics and Metrology Group at Diamond Light Source, describes a new metrology instrument and techniques their team has developed. Based on speckle angular measurement (SAM), it can surpass current metrology techniques and provide unprecedented accuracy for characterizing strongly curved high-quality X-ray mirrors.

|

|

Modern synchrotron radiation facilities and X-ray free electron lasers provide high-brilliance X-rays for cutting-edge scientific and industrial research. The successful exploitation and efficient utilization of X-ray beams depends on the quality of the optics used.

|

|

X-ray mirrors are critical optical components and widely used for their exceptional characteristics of high efficiency and inherent achromaticity. The height error (surface deviations from the ideal profile) of X-ray mirrors inevitably deteriorates the wavefront and focal performance. For the most demanding X-ray applications such as extreme energy resolution or nano-focusing, the required height error is often below 1 nm rms. The manufacturing and metrology of X- ray mirrors thus pose major challenges.

|

|

Dr Hongchang Wang, Senior Optics Scientist and lead author of the study, explains the advantages of the new technique: “The speckle-based metrology instrument, SAM, we have developed is a compact, low-cost instrument that is easy to integrate with most other existing X-ray mirror metrology instruments. Importantly, it allows accurate measurement of strongly curved mirrors in two dimensions with a precision of nanometers. This is a feature that most existing metrology instruments lack and bridges the gap faced in their capabilities by the X-ray mirror metrology community. The quote, ‘If you can’t measure it, you can’t improve it’, is especially true in the fabrication and characterization of super-polished X-ray mirrors.”

|

|

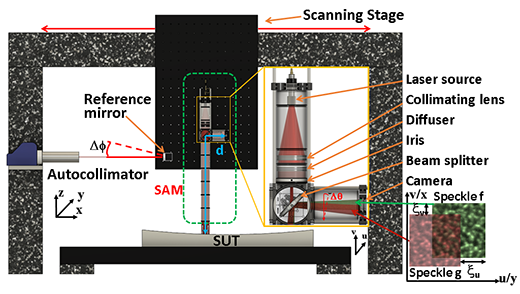

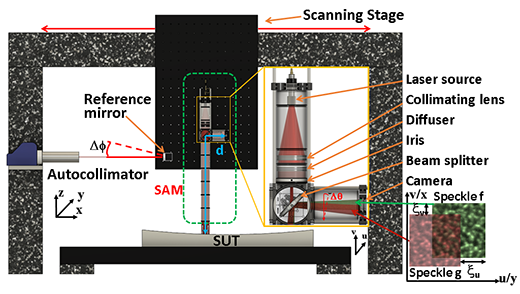

| Schematic representation of the experimental setup for speckle angular measurement (SAM). The SAM instrument is attached to the air bearing scan stage, and the speckle pattern from the reflected mirror surface shifts when the speckle is projected onto different parts of the surface under test (SUT). The angle change can be calculated from the speckle displacement between two speckle subset images (f and g) by employing the sub-pixel tracking algorithm. The carriage slide’s pitch error is measured with an autocollimator, and the change of the SUT’s slope is derived from the SAM and the autocollimator (AC) angle. (click on image to enlarge)

|

|

In the paper the team demonstrate that the angular precision of slope error measurements can be pushed down to 20nrad rms by utilizing an advanced sub-pixel tracking algorithm. The team say that this new nano metrology method can potentially open new possibilities to develop next-generation super-polished X-ray mirrors which will also advance the development of synchrotron radiation, free electron lasers, X-ray nanoprobes, coherence preservation, astronomical physics and telescopes.

|

|

Co-author of the paper on this new metrology technique, Prof. Kawal Sawhney, Principal Beamline Scientist and Optics and Metrology group leader at Diamond, adds: “This novel instrument will enhance the capabilities of our state-of-the-art metrology laboratory at Diamond and enable us to metrology test the extremely high-quality X-ray mirrors required for use with the planned upgrade of Diamond to a low-emittance Diamond-II source. Vendors of X-ray mirrors will also find this new instrument attractive as it will enable them to fabricate even better-quality optics than at present.”

|

|

High-precision X-ray mirrors are continuously improved and developed to keep pace with the worldwide upgrades of synchrotrons to diffraction-limited storage ring. To overcome the limitations of present metrology techniques, the team developed this new SAM optical scanning head and approach, recognizing that more accurate measurements of mirror figures will be essential for next-generation X-ray mirrors to enable them to take advantage of improved light sources and meet new demands.

|

|

The SAM setup is deceptively simple (Fig.). 2D random intensity patterns (speckle) are generated by shining a laser through a diffuser and they can be treated as multiple pencil beams with different features. Because each speckle pattern has unique features, the speckle may be treated as a set of multiple wavefront markers. Variations of mirror slope over the measured area of the mirror shift the speckle pattern. The slope variation of the surface under test (SUT) can then be measured at the nanoradian level in two dimensions by precisely tracking the speckle displacement with an advanced sub-pixel algorithm.

|

|

The SAM can be easily installed on an existing ex-situ metrology gantry. It can generate 2D surface profiles, providing rich information about the surface profile of X-ray mirrors. In addition to the larger scanning angle range and excellent repeatability, high precision is achieved. The SAM instrument can also be potentially used to measure toroidal, ellipsoidal and paraboloidal mirrors by performing 2D raster scans of SAM across the entire mirror surface. Finally, the SAM instrument is not confined to synchrotron X-ray mirrors but can also be applied to freeform optics and to high-quality mirrors in other fields, such as extreme ultra-violet lithography and laser ignition.

|

|

It becomes more and more challenging for currently available metrology techniques to guide the latest efforts to improve the manufacturing quality of X-ray mirrors. The new technique and instrument based on SAM uses very large number of speckles and provides better statistics and less random noise even in a single image. This remarkable feature will potentially enable the proposed SAM metrology technique to be widely used for super-precision metrology and advancement of the next generation of X-ray mirrors.

|

|

Laurent Chapon, Physical Sciences Director at Diamond comments; “This exciting new technique of speckle angular measurement intensively developed by members of Diamond’s Optics and Metrology Group, will be able to expand the capabilities of current metrology instruments. For the next generation of X-ray mirrors, required to keep up with new X-ray sources and the ever-increasing demand for greater coherence and tighter focusing, SAM will be a timely source of aid.”

|

|

Diamond’s Optics and Metrology Group used its Test Beamline (B16) to develop this advanced X-ray imaging and metrology approach. Recently, a speckle-based omnidirectional differential phase and dark-field imaging has been demonstrated and published in the Proceedings of the National Academy of Sciences ("Hard X-ray omnidirectional differential phase and dark-field imaging"). The team has now successfully transferred, this speckle technique from X-ray to visible light region.

|