| Apr 07, 2022 |

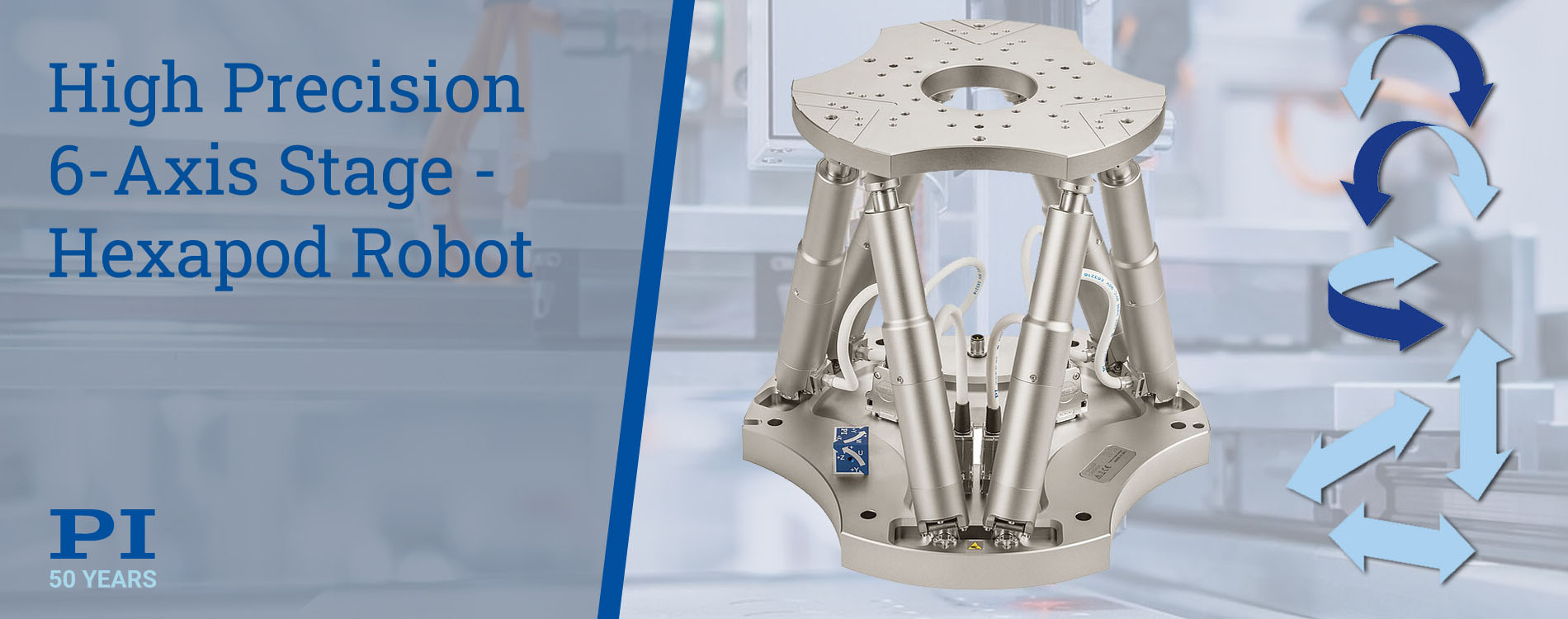

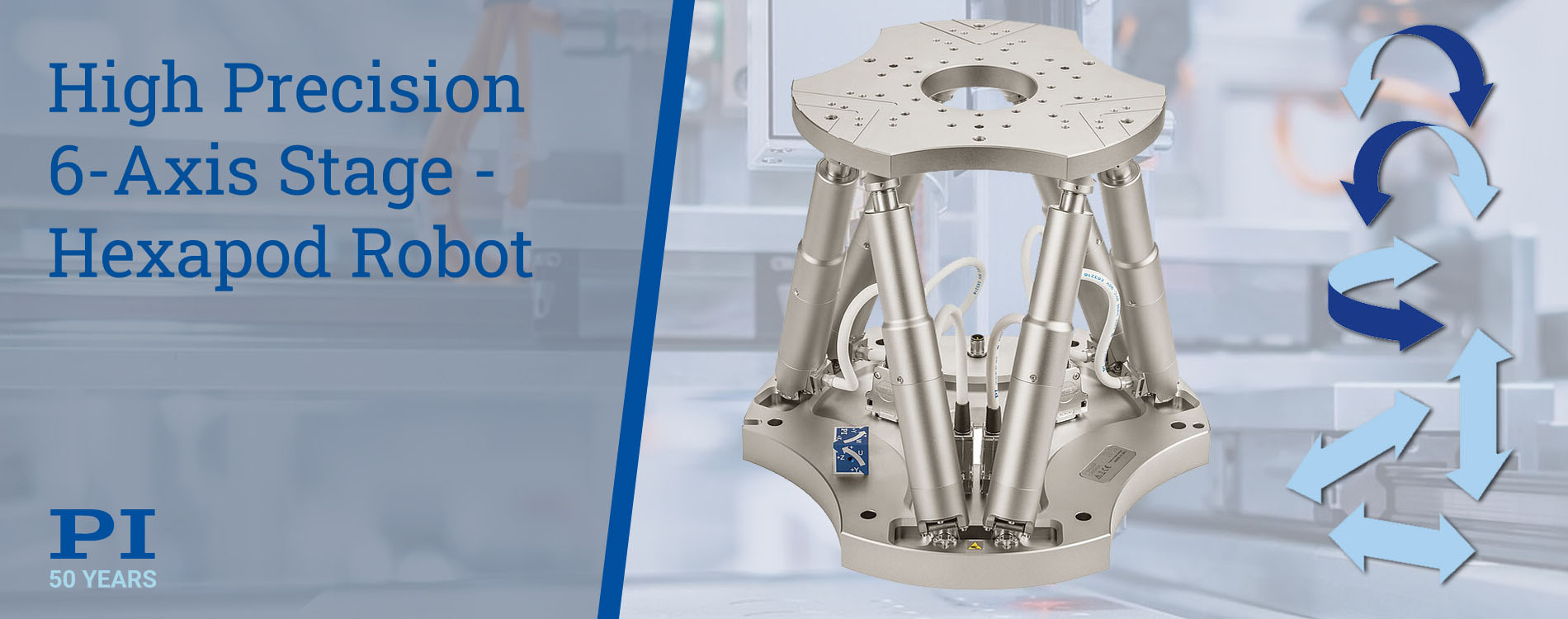

6-Axis Stage based on Precision Hexapod Micro-Robot is Designed for New Nano-Positioning Applications

(Nanowerk News) PI has added to its family of compact hexapod 6-axis stages based on the Stewart Platform principle. The H-840.G2IHP micropositioning robot is equipped with brushless precision motors for high performance and high duty cycle applications.

|

|

Designed for multi-axis alignment and positioning applications in fields such as optics, photonics, aero-space, and bio-medical engineering, the hexapod micro-robotic stage provides 6 degrees of freedom, step resolution of 20 nanometers, repeatability to ±0.1 micrometers, 40kg load capacity, and travel ranges to 100mm (linear) and 60° (rotation).

|

|

Addressing all six degrees of freedom means that this compact micropositioning robot can provide linear motion in X, Y, Z as well as rotations in Theta-X, Theta-Y, and Theta-Z (pitch, yaw, roll).

|

|

| High performance, cost-effective, 6-axis stage based on a Hexapod micropositioning robot for industrial high precision multi-axis motion control and automation applications. (Image: PI)

|

Hexapod Stage Applications

|

|

Examples of hexapod 6-axis stage applications can be found in in optics and tool inspection, bio-medical and life sciences, micromanufacturing & micromanipulation, and industrial alignment of precision components.

|

Advantages of the Hexapod Stewart Platform Design Principle

|

|

The advantage of the Stewart Platform parallel kinematic design over traditional 5-axis and 6-axis stages is the fact that there is only one moving platform, supported by six closed-loop actuators. This parallel operation also provides identical dynamics for all 6 axes, in contrast to traditional multi-axis stacked-stages, where each stage sees a different load, and the motor on the bottom stage has to move the mass of its own motion platform as well as up to 5 additional stages stacked on top.

|

|

The design symmetry of the hexapod Stewart Platform also enables a large central aperture and eliminates the need for dragged cables – there are only 2 stationary external connections for power and data going to the fixed bottom platform.

|

High Duty Cycle – Design for Precision Industrial Alignment and Automation Applications

|

|

The above advantages and the design with its long-life brushless motors, low friction ball-screw actuators and ultra-stiff cardanic joints, make the H-840 six-axis stage ideal for automated industrial precision alignment applications. A powerful 6-axis motion controller with built-in multi-axis alignment routines and a host of software examples and drivers reduces the startup time and facilitates integration into existing control structures.

|

Hexapod Motion Controller / Motion Software

|

|

PI’s hexapod 6-axis motion controllers and hexapod software are based on decades of experience with parallel kinematic motion systems. They are easy to program, allow the user to change the center of rotation with one command, and come with high level alignment functions built in. PI’s hexapod motion simulator software calculates the limits of workspace and load capacity, thereby ensuring the hexapod you choose will handle the loads, forces, and torques in your application.

|

|

Datasheet: H-840.G2IHP Hexapod 6-Axis Robotic Stage

|

About PI

|

|

PI is a privately held company that designs and manufactures world-class precision motion and automation systems including air bearings, hexapods and piezo drives at locations in North America, Europe, and Asia. The company was founded 5 decades ago and today employs more than 1400 people worldwide. PI’s customers are leaders in high-tech industries and research institutes in fields such as photonics, life-sciences, semiconductors, and aerospace.

|