| Nov 20, 2018 | |

Layer-exchange growth of graphene directly on insulating material(Nanowerk News) Graphene on arbitrary substrates is a key to combine advanced electronic devices with carbon materials. For devices meant to withstand large currents or heat, thick multilayer graphene (MLG) is preferred over few-layer graphene. |

|

| For example, low-resistance wiring requires a thickness of tens of nanometers to replace copper wiring in large-scale integrated circuits, whereas a heat spreader requires a thickness of more than several micrometers, depending on the type of the device. | |

| However, current vapor deposition techniques, including chemical vapor deposition and plasma-assisted vapor deposition, have difficulty forming thick, uniform MLG on insulating materials. | |

| On the other hand, metal-induced solid-phase crystallization of amorphous carbon (a-C) or polymers has attracted increased attention for the direct synthesis of MLG on insulators. | |

| Some of these techniques have allowed the synthesis of thick (>5 nm) MLG by controlling the initial thickness of amorphous carbon. However, further investigations were necessary to achieve a high-quality uniform MLG on insulators. | |

|

|

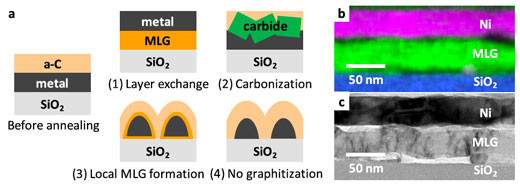

| Overview of the study. (a) Schematic sample structure and interactions between metals and a-C classified into four groups. Representative results showing layer exchange: cross-sectional (b) elemental mapping and (c) transmission electron microscopy (TEM) image of the sample grown by Ni-induced layer exchange. (Reprinted with permission by American Chemical Society) | |

| Reporting their findings in ACS Applied Materials & Interfaces ("Metal Catalysts for Layer-Exchange Growth of Multilayer Graphene"), researchers in Japan have developed a technique that uses 'layer exchange' to grow high-quality uniform crystals of MLG directly on an insulating material. | |

| In this study, the scientists examine the potential of 15 kinds of transition metals (Ni, Co, Fe, Cr, Mn, Ru, Ir, Pt, Ti, Mo, W, Pd, Cu, Ag, and Au) to be used as catalysts for the metal-induced layer-exchange growth of MLG. The interaction between metal and carbon is summarized from the perspective of the periodic table. | |

| All the team's samples started with a stacked structure of an a-C/metal/SiO2 substrate and were then annealed at 600-1000°C for 1 hour in ambient Ar. From the experimental results, the interactions between the metals and a-C were classified into four groups: layer exchange; carbonization; local multilayer graphene formation; and no graphitization. | |

| This classification was related to the arrangement of each element in the periodic table. In particular, layer exchange was achieved for the metals Co, Ni, Cr, Mn, Fe, Ru, Ir, and Pt. | |

| The metals that allowed for layer exchange demonstrated the following tendency: metals with high C solid solubility induced low-temperature MLG synthesis, whereas metals with low C solid solubility produced high-quality MLG. | |

| "The guidelines constructed in this study will play an important role in developing the research of growing MLG on substrates that could be used in advanced electronic devices," the authors conclude. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |