| Mar 09, 2022 |

Graphene-coated gold electrodes for anticorrosion in wearables

(Nanowerk News) Gold has been widely adopted in biosensors for its biocompatibility and in flexible electronics for its ductility. Despite the common perception that gold is chemically inert for use as electrochemical electrodes, it is still prone to surface oxidation or corrosion

|

|

Ultra-thin graphene coatings have already been demonstrated as corrosion-resistant surface coatings for metals (read more: "Graphene beats polymer coatings in preventing microbially induced corrosion").

|

|

In addition, adding a few graphene layers onto conventional gold-film surface plasmon resonance (SPR) biosensor will boost up its sensitivity dramatically. The improved sensitivity comes from the graphene layers' increased adsorption of biomolecules (read more: "Highly sensitive graphene biosensors based on surface plasmon resonance").

|

|

Avoiding complicated preprocessing steps of CVD graphene growth and the required high temperatures of plasma-enhanced CVD (PECVD), researchers have now demonstrated the feasibility of direct growth of graphene on gold thin films by PECVD at low temperature.

|

|

The researchers from California Institute of Technology report their findings in ACS Applied Nano Materials ("Graphene on Nanoscale-Thick Au Films: Implications for

Anti-corrosion in Smart Wearable Electronics").

|

|

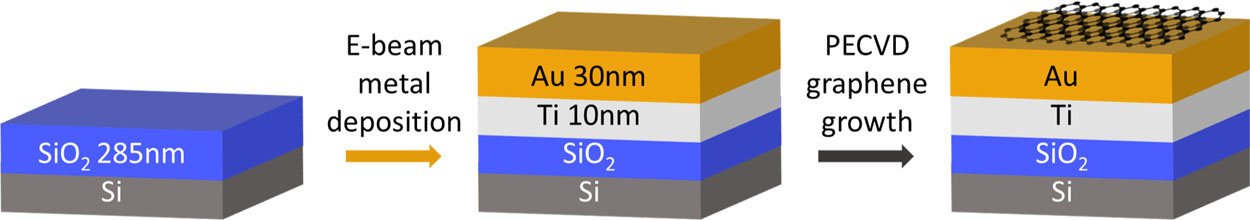

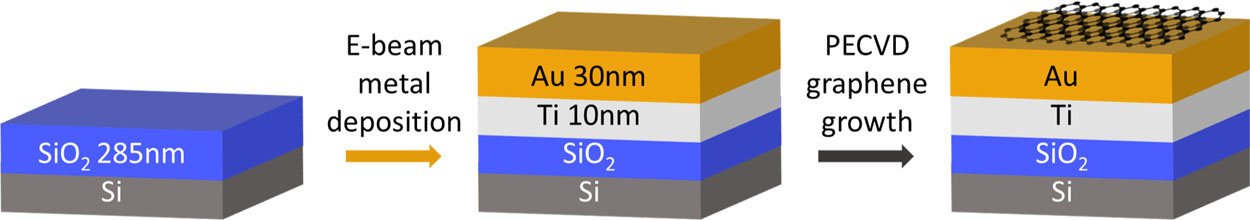

| Schematic of the substrate structure along with the subsequent PECVD graphene growth. (Reprinted with permission by American Chemical Society)

|

|

As illustrated above, the substrate in this work consists of a gold thin film of 30 nm thickness above a Ti layer of 10 nm thickness, both deposited on a SiO2/Si substrate with a SiO2 thickness of 285 nm via an electron-beam evaporator.

|

|

Through plasma heating, the temperature during graphene growth was about 120 °C. To transfer the graphene grown on Au/Ti/SiO2/Si to a SiO2/Si substrate, polymethyl methacrylate (PMMA) was spin-coated on the graphene-covered Au/Ti/SiO2/Si substrates followed by gold etching. Subsequently, the transferred graphene on SiO2/Si was soaked in acetone for PMMA removal.

|

|

The researchers investigated the surface morphology and crystallinity of gold using AFM and XRD, respectively, and they found it to be dependent on the H2/CH4 ratio used during the PECVD process.

|

|

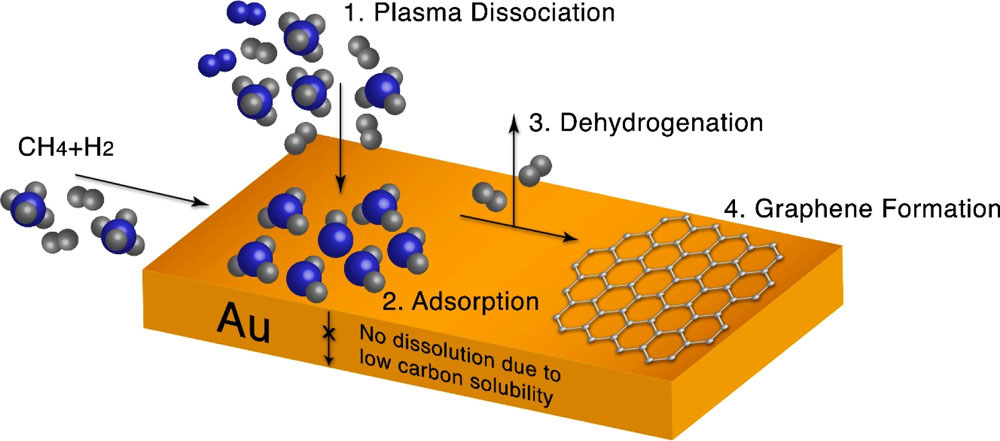

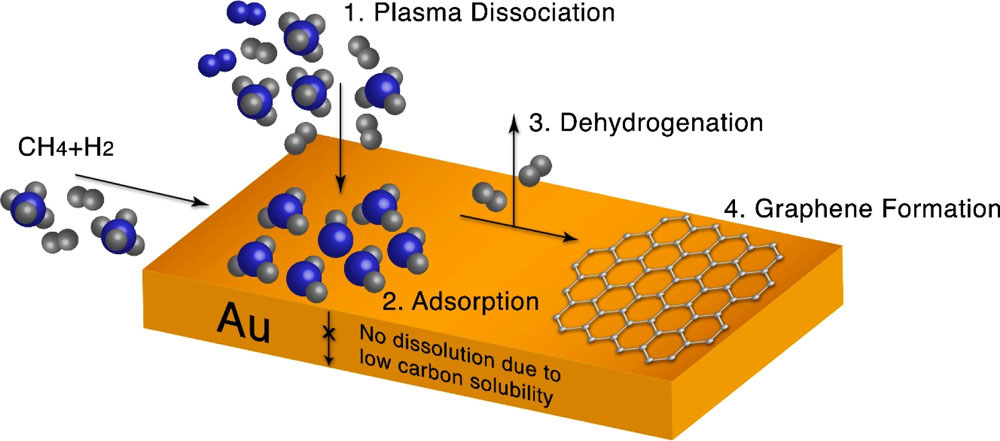

| Schematic of the growth mechanism of graphene on gold by PECVD. (Reprinted with permission by American Chemical Society)

|

|

ADF-STEM images also verified that the number of graphene layers grown on gold was related to the growth condition of the H2/CH4 ratio. For instance, for a H2/CH4 ratio of 0.2, they observed mainly monolayer graphene, while for H2/CH4 greater 1, they found primarily bilayer graphene.

|

|

By accelerated soak testing in oxygenated saline solution, the team was able to demonstrate excellent

anti-corrosion performance of their graphene-on-gold coating.

|

|

The authors conclude by noting that their work of low-temperature direct growth of graphene on gold by PECVD appears promising for anti-corrosion in smart wearable, implantable, and flexible hybrid electronics, where sweat and body fluids could have corrosive effects on common electrode materials.

|

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC