| Posted: June 29, 2009 |

New method vastly improves nanotechnology coatings for implants |

|

(Nanowerk News) Tel Aviv University researcher Prof. Noam Eliaz of the TAU School of Mechanical Engineering has developed an electrochemical process for coating metal implants which vastly improves their functionality, longevity and integration into the body.

|

|

The new process could vastly improve the lives of people who have undergone complicated total joint replacement surgeries so they can better walk, run and ultimately avoid rejection of the implant by their bodies.

|

|

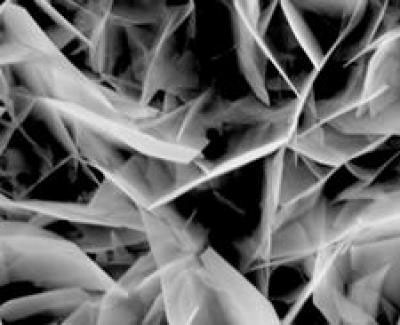

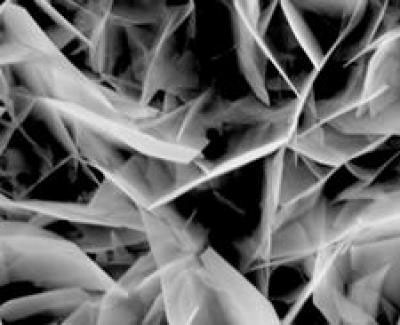

| This is an image of electrochemically-deposited crystals from a scanning electron microscope. (Image: American Friends of Tel Aviv University)

|

|

"The surface chemistry, structure and morphology of our new coatings resemble biological material," explains Prof. Eliaz. "We've been able to enhance the integration of the coating with the mineralized tissue of the body, allowing more peoples' bodies to accept implants." His new coating resulted in a 33% decrease in the level of materials failure, or delamination, in these implants.

|

|

Prof. Eliaz presented his findings to the 215th meeting of the Electrochemical Society in San Francisco in May 2009. In addition, a new 12-week implantation study, recently published in the journal Acta Biomaterialia, favorably compared the performance of the Tel Aviv University coatings to those of current commercial coatings.

|

|

Giving your joints an electrochemical bath

|

|

Today's surgeons can reconstruct joints in the human body using metal structures implanted to take the place of the natural joint. In order to better integrate the new addition to the adjacent bone, implants are often coated with synthetic hydroxyapatite, which is similar to the main inorganic constituent of enamel, dentin and vertebrate bone. The properties of this coating are crucial to the function and life of the implant in the body.

|

|

Prof. Eliaz's advance is in the application technique of the coatings rather than the elements used in the coatings themselves. Instead of the traditional plasma-spraying technique, he and his team from the Tel Aviv University Materials and Nanotechnologies Program have developed a way to electrochemically deposit synthetic hydroxyapatite. In place of plasma-spraying the coating onto the metal, the metal implant is placed into a bath of electrolyte solution and an electric current is applied.

|

|

|

|

According to Prof. Eliaz, a good coating is crucial to the stable fixation of the implant in the surrounding bone. Since human bones naturally contain apatite, covering the implant with a synthetic version allows the body to register the implant as similar to a real bone. This ensures integration and fixation of the implant, and also prevents poisonous materials from leaking from the metal of the implant into the blood stream.

|

|

Could spur new bone growth

|

|

Prof. Eliaz has discovered that his method of coating circumvents the disadvantages of plasma- spraying. The electrochemical process allows synthetic hydroxyapatite to more closely mimic the real material. Examined under a microscope, it is virtually indistinguishable from the body's own material — which helps the body accept a new implant.

|

|

The next-generation coating will include nano-particles to reinforce the coating. It will also have the potential to incorporate biological material or drugs during the process itself.

|

|

"We can incorporate biological materials" because the electrochemical process works at lower temperatures, says Prof. Eliaz. "The reinforcement of nanoparticles will improve the mechanical properties and may also improve the biological response. Drug incorporation may reduce the risk of post-surgery infection and even catalyze the growth of the bone."

|