| Aug 13, 2014 |

How spiders fix their webs

|

|

(Nanowerk News) Spider silk is light and delicate, while incredibly resilient and tear-resistant. Understanding the structure and way of construction of these threads is a challenge taken up by a research team of Kiel University. The scientists examined five different spider species regarding the adhesion and tensile strength of a particular silk they use to fix the main thread to a surface. As shown in their new study published in the international Journal of the Royal Society Interface ("Composition and substrate-dependent strength of the silken attachment discs in spiders"), the scientists found out that the substrate has a particularly significant impact on the silk’s adhesion.

|

|

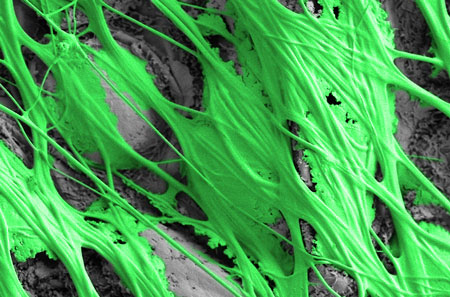

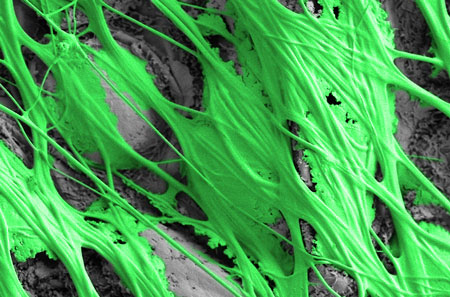

| Attachment disc (green) spun on a leaf (grey) as displayed by scanning electron microscopy. (Image: Jonas Wolff)

|

|

The research group led by Professor Stanislav Gorb (Institute of Zoology, Kiel University) has attended to the functional analysis of animal surfaces. Why do a gecko’s feet adhere to a wall? Why does a snake’s skin not fray out while the snake is moving forward? The group’s most recent study object is spider silk: spiders use the so-called safety thread to prevent them from falling, to lower themselves and to build the web’s framework. The threads are fixed to the surface and other threads by means of so-called attachment discs generated by rotating motions of the silk glands and applied in the form of a special lattice pattern.

|

|

The scientists of Stanislav Gorb’s research team investigated how attachment discs adhere to various surfaces.

|

|

“To this end, we placed the spiders on glass, Teflon and the leaf of a sycamore maple, and they produced attachment discs on each surface. Subsequently, we performed tensile tests to measure the strength necessary to detach the discs from the substrate”, says the author of the current study, Jonas Wolff.

|

|

According to Wolff, the silk adhered so tightly to the glass surface that the threads were torn apart before they came off, while the attachment discs produced on the Teflon substrate could be detached completely. However, even on the Teflon surface the discs’ adhesion was in most cases sufficient to bear a multiple of the spider’s weight.

|

|

“On the surface of the leaf, adhesion is eventually reduced to a level where the attachment discs most often come off completely”, adds Wolff.

|

|

The scientists explain this phenomenon with the fact that vegetable surfaces often contain microstructures and/or waxes which make it harder for herbivorous insects to walk on them. As a matter of course, spiders have to face this problem as well if they want to build their webs between plants.

|

|

“We assume that the competition between plants and herbivorous insects presented an evolutionary pressure for spiders to develop better adhesives”, says Wolff.

|

|

Currently, the team is examining the exact structure and functionality of the attachment discs. “Our findings might be of great value for the development of novel, highly efficient, economical and ecological adhesives”, says project supervisor Gorb with regard to the applications possibly resulting from this research.

|