| Jun 07, 2018 |

Engineered proteins could improve biomanufacturing production of medicines, fuels

|

|

(Nanowerk News) Purdue University researchers have developed a series of engineered proteins that could improve biomanufacturing processes for the production of biofuels, pharmaceuticals and commodity chemicals.

|

|

The buildup of toxic materials during the production process can damage cell health and typically lowers the overall amount of product that is made. Few tools are available to broadly address this issue.

|

|

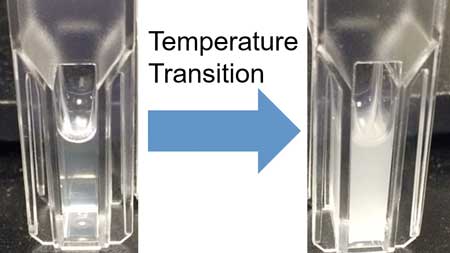

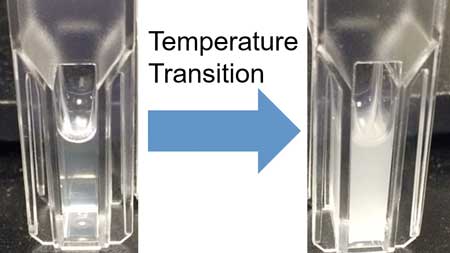

| Purdue designer proteins reversibly aggregate (become a white solid) under conditions of cellular stress to increase biomanufacturing efficiency by reducing transcription factor availability and decreasing stressful gene expression. (Image: Purdue University)

|

|

Kevin Solomon, an assistant professor in the Purdue Department of Agricultural and Biological Engineering, and his team developed a series of engineered proteins derived from elastin-like polypeptides, or single linear chains of amino acids. ELPs have an inverse phase change property of aggregating in response to specific environmental triggers such as temperature and pH. The researchers fused these ELPs to transcription factors, proteins that bind to DNA, to control gene expression and regulate the buildup of toxic materials.

|

|

“Our transcriptional regulators recognize generic signals of toxicity and, thus, can be applied to pathways for the production of many compounds,” Solomon said. “These regulators are tunable, by controlling the ELP structure, to create feedback that only triggers at preprogrammed setpoints.”

|

|

The regulators are easily tailored to different biomanufacturing processes by selecting an appropriate transition setpoint for a given production pathway. They provide a generic tunable platform with clear design rules that can be developed for any process. Current approaches are product-specific and difficult to adapt.

|

|

“Our system is programmable, meaning that we can make specific changes in the ELP sequence that allow us to tailor its transition property, therefore, allowing us to create a library of ELPs that transition under various conditions,” said Logan Readnour, a graduate student in agricultural and biological engineering and a member of Solomon’s research team. “We are able to target specific genes for regulation and because we use a transcription factor that is not native to the cell, it does not interfere with the native processes already present within the cell.”

|

|

By improving cell health during the biomanufacturing process, the researchers hope to optimize yields of valuable products such as medicines and fuels.

|

|

“This technology will help us move to more sustainable bioproduction that replaces or complements products from dwindling petroleum reserves, while using less harsh and dangerous chemicals,” Solomon said.

|

|

A patent application has been filed by the Purdue Office of Technology Commercialization and the technology is available for licensing.

|