| Mar 05, 2018 |

Hydrogen extraction breakthrough could be game-changer

|

|

(Nanowerk News) Researchers at KTH Royal Institute of Technology have successfully tested a new material that can be used for cheap and large-scale production of hydrogen – a promising alternative to fossil fuel.

|

|

Precious metals are the standard catalyst material used for extracting hydrogen from water. The problem is these materials - such as platinum, ruthenium and iridium - are too costly. A team from KTH Royal Institute of Technology recently announced a breakthrough that could change the economics of a hydrogen economy.

|

|

Led by Licheng Sun, professor of molecular electronics at KTH, the researchers concluded that precious metals can be replaced by a much cheaper combination of nickel, iron and copper (NiFeCu).

|

|

"The new alloy can be used to split water into hydrogen,” says researcher Peili Zhang. “This catalyst becomes more efficient than the technologies available today, and significantly cheaper.

|

|

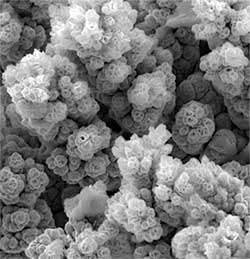

| Electron microscope image depicts the water splitting alloy. (Image: KTH The Royal Institute of Technology)

|

|

“This technology could enable a large-scale hydrogen production economy,” he says. Hydrogen can be used for example to reduce carbon dioxide from steel production or to produce diesel and aircraft fuel.

|

|

It’s not the first time a cheaper material has been proposed for water splitting, but the researchers argue that their solution is more effective than others. They published their results recently in the scientific journal Nature Communication ("Dendritic core-shell nickel-iron-copper metal/metal oxide electrode for efficient electrocatalytic water oxidation").

|

|

“The high catalytic performance of core-shell NiFeCu for water oxidation is attributed to the synergistic effect of Ni, Fe and Cu,” Zhang says.

|

|

Zhang says that copper plays an interesting role in the preparation of the electrode. In an aqueous solution, surface copper dissolves and leave a very porous structure to enhance the electrochemically active surface area. "The porous oxide shell with its high electrochemically active surface area is responsible for the catalytic activity, while the metallic cores work as facile electron transport highways," Zhang says.

|

|

Sun has previously made progress in this field of research, including the construction of artificial photosynthesis (Nature Chem. 4/2012), and a catalyst based on nickel and vanadium (Nature Com. 7/2016). His and colleagues' research was one of the reasons that US President Barack Obama went to KTH in 2013 during the second-ever state visit of an American president in Sweden.

|