| Jul 05, 2018 |

Solar Fuels could become competitive in the 2030s

|

|

(Nanowerk News) The industrial synthesis of renewable hydrogen, syngas, methanol and diesel could become competitive with respect to their fossil counterparts within the next two decades. This follows from a techno-economic analysis by researchers from the University of Amsterdam's (UvA) research priority area Sustainable Chemistry and TNO.

|

|

They will publish their findings shortly in the journal Energy & Environmental Sciences ("The future of solar fuels: when could they become competitive?").

|

|

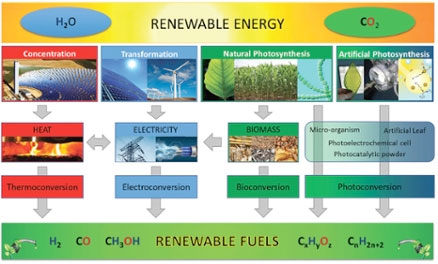

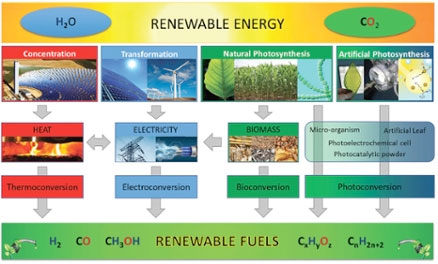

| Overview of the production of renewable fuels by means of solar energy driven processes with H2O and CO2 as basic feedstocks.

|

|

Solar energy driven processes with H2O and CO2 as basic feedstocks can produce 'solar fuels', replacing their fossil-based counterparts. These 'renewable fuels' are key to sustainable future energy systems, not only as an energy carrier in, for example, transportation, but also as a potential storage medium in the power sector. They can also provide fundamental 'green' building blocks for the chemical industry.

|

|

Remko Detz, Joost Reek and Bob van der Zwaan analysed multiple technologies required to produce renewable hydrogen, syngas, methanol, and diesel. By applying ‘learning curves’ associated with individual system components, they project decreases in investment costs and reductions in fuel production costs.

|

Rapid cost reductions and a high efficiency

|

|

Following an optimistic scenario the three researchers conclude that all four renewable fuels can out-compete their fossil-based counterparts between 2025 and 2050.

|

|

For hydrogen production through electrolysis and diesel production by Fischer–Tropsch synthesis, even a more conservative scenario may result in break-even costs before 2040. Both processes use solid oxide electrolysis, which according to the researchers will profit from rapid cost reductions and a high efficiency. First author Remko Detz: ‘We consider solid oxide electrolysis an early winner. But to achieve its potential, current systems with a typical size of 150 kW must be scaled up to the MW level.’

|

Investing in learning-by-doing

|

|

In general, Detz says, the study reveals that the selected renewable fuels can become a valuable option for replacing current fossil fuel-based products. ‘Whether they will truly become competitive depends on many factors, such as installed capacity, taxes, subsidies, other policies, and the price of CO2. Our results show, however, that the costs to produce renewable fuels can drop significantly over the coming decades.’ Detz adds that it is of prime importance to invest in research in these technologies as well as in approaches to stimulate learning-by-doing: ‘Efforts to improve the scalability, efficiency, integration, and affordability of the necessary components are all important aspects for successful large-scale deployment.’

|

Four common fuels

|

|

The study focused on four common fuels – hydrogen, syngas, methanol, and diesel – because these can be generated relatively easily through renewable energy pathways. In total, seven renewable fuels production routes were studied – four for hydrogen and one for each of the other three fuels. These show high technology readiness levels, or – in particular in the case of novel artificial photosynthesis - hold the promise for straightforward renewable fuel production.

|

|

According to Detz, ‘novel artificial photosynthesis approaches should definitely be pursued, since their novelty implies that they could learn rapidly and thereby yield fast cost reductions.’ As an example, he mentions the manufacturing of a fully integrated conversion device in which light harvesting, charge separation, and catalysis produce the desired renewable fuel in a single step. This has the potential to substantially reduce investment costs, which can be deduced from analogous integrated systems such as PV cells producing electricity.

|