| Jan 12, 2022 |

Recycling already considered in the development of new battery materials

|

|

(Nanowerk News) Enormous ecological and economic potential consists in the circular value chain of batteries: The use of recycled materials not only reduces the costs of raw materials, but also enables energy savings in battery production.

|

|

A review article on battery recycling published in the scientific journal Advanced Energy Materials ("Recycling of Lithium-Ion Batteries—Current State of the Art, Circular Economy, and Next Generation Recycling") provides an overview of the challenges of new material concepts for battery recycling, “Design for Recycling” as a promising approach of a sustainable battery economy as well as regulations and new battery directive demands in the United States, the European Union (EU) and China.

|

|

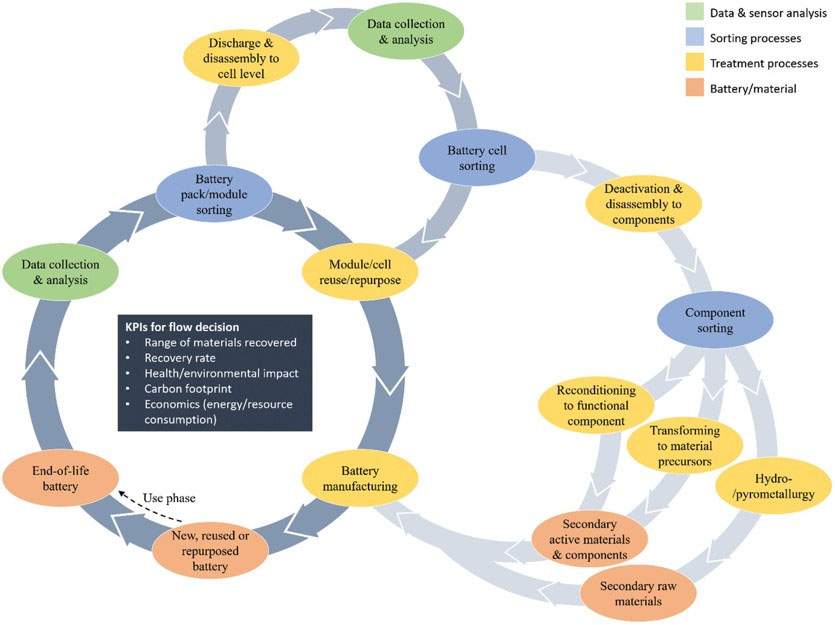

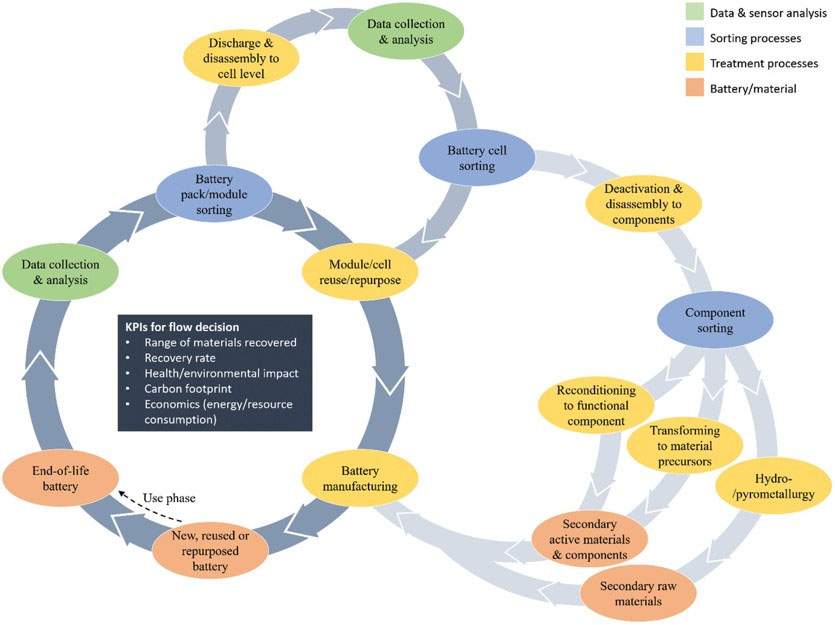

| Proposed framework for the development of future recycling infrastructures. (Image: University of Münster)

|

|

“The dynamic development of the battery market is also reflected in the materials used. A mix of materials is often used as active materials, which complicates achieving high recycling efficiencies and purities of the different raw materials”, explains Dr Sascha Nowak, Head of Analytics and Environment Division at MEET Battery Research Center of the University of Münster.

|

|

In addition, certain active materials such as lithium iron phosphate (LFP) have a lower intrinsic material value compared to lithium nickel cobalt manganese oxide (NCM). The profitability of recycling such materials is therefore reduced.

|

|

According to the research team, one approach to overcome existing and new challenges is the concept “Design for Recycling”. It aims to standardise screw connections and conjunctions between modules or cells in order to facilitate an automated disassembly of the cells.

|

|

Moreover, the approach includes the design of materials. For example, water-based binder systems for electrode materials are to be developed to reduce expensive, potentially toxic solvents during recycling. Another possibility is direct recycling.

|

|

“In this process, active materials, mainly from the cathode, are reactivated after use by relithiation for direct assembly in new cells – without a complete resynthesis of the materials having to take place”, Jonas Neumann, PhD student at MEET Battery Research Center, explains.

|

|

These and other processes are regulated by laws for battery recycling in some parts of the world. In the EU and China, battery producers are financially and physically responsible for the recycling of their batteries pursuant the “Extended Producer Responsibility (EPR)”. In addition, there are regulations for collection rates of used batteries, material recovery targets and labelling standards. The regulations in the United States are particularly focused on the recycling of nickel-cadmium and lead-acid batteries. More comprehensive requirements including the recycling of lithium ion batteries are only valid in four states so far.

|