| May 08, 2013 |

Metallic glass: How nanoscale islands react under strain

|

|

(Nanowerk News) Quick-cooling molten atoms give metal alloys a glassy, or random, atomic structure that generates higher elasticity and better wear- and corrosion-resistance than their crystalline alloy counterparts. However, these ‘metallic glasses’ also suffer from brittleness that makes them shatter. Findings from Yong Wei Zhang of the A*STAR Institute of High Performance Computing in Singapore and co-workers may now make it easier to use metallic glass in practical engineering applications ("On the characteristic length scales associated with plastic deformation in metallic glasses"). They have discovered that a fundamental relationship between material plasticity and atomic ‘islands’, known as ‘shear transition zones’ (STZs), enables precise measurement and prediction of fracturing in these materials.

|

|

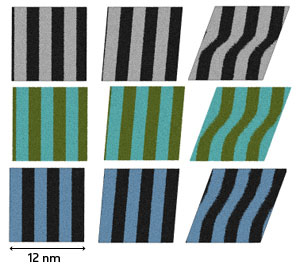

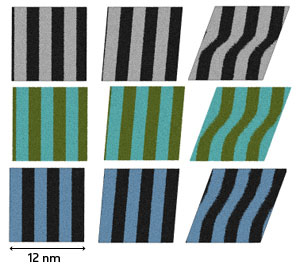

| Snapshots of atomic movements captured during simulations of FeP (top), MgAl (middle) and CuZr (bottom) metallic glasses undergoing increasing mechanical strain (left to right).

|

|

When an external force strains a metallic glass, most of its atoms respond elastically and try to return to their original positions. Researchers believe that shattering occurs when STZs appear and begin to deform irreversibly. If present in high enough numbers, the STZs will generate shear bands that propagate through a cascade-like process and make the glass fracture.

|

|

Despite their importance, defining the extent of STZs remains a point of controversy among researchers. Zhang and co-workers used atomic calculations to explore the development of STZs within three metallic glasses — iron–phosphorous (FeP), magnesium–aluminum (MgAl) and copper–zirconium (CuZr). They selected these materials because of their increasingly different ‘Poisson’s ratios’, a mechanical constant that describes how a material ‘pinches in’, like a rubber band, when pulled lengthwise. Zhang and co-workers suspected that this ratio could be related to STZ formation.

|

|

They first simulated mechanical strain in each of the three types of metallic glass (see image) and observed whether the atomic movements were plastic or irreversible. Then, they correlated the plastic movements with a mathematical function based on interatomic distances. Intriguingly, they discovered that they could extract a constant ‘characteristic length’ parameter to measure the size of STZ islands that developed during deformation.

|

|

Zhang explains that the nanoscale lengths of STZs are reminiscent of ‘defects’ seen in crystalline metals, and their positive correlation with the Poisson’s ratio of a material can help predict fracture problems. Their calculations showed that bigger STZ islands had more resistance to pinching in, and shattered only when relatively large shear bands formed.

|

|

By connecting basic materials physics to atomic deformation zones, the team hopes to lay the groundwork for a new generation of metallic glasses with greater resistance to brittle fracture. “Understanding the connection between Poisson's ratio, STZ size and fracture toughness is very important for the development of metallic glasses with good mechanical properties,” says Zhang.

|