| Jun 12, 2013 |

New additive offers near-perfect results as nucleating agent for organic semiconductors

|

|

(Nanowerk News) Pixie dust may be the stuff of fanciful fiction, but for scientists at UC Santa Barbara’s Department of Materials, a commonly used sugar-based additive has been found to have properties that are near magical. By adding minute amounts of it during the fabrication of organic semiconductors, they have been able to dramatically increase yield and control crystallization, which could, in the near future, make the technology not only cheaper and more accessible, but also enhance its performance. Results of their study are published in the recent issue of the journal Nature Materials ("Microstructure formation in molecular and polymer semiconductors assisted by nucleation agents").

|

|

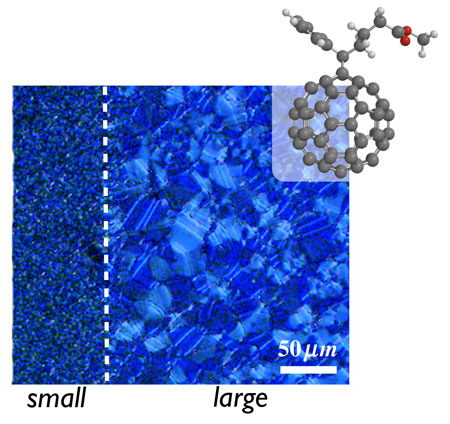

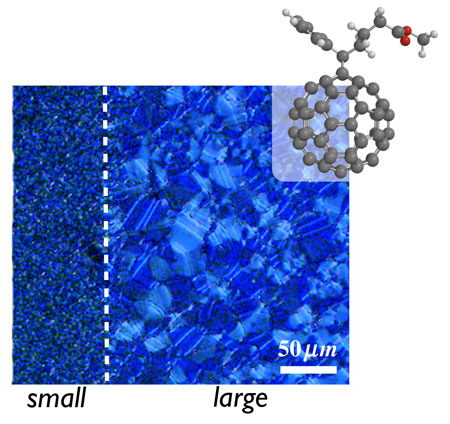

| Optical microscopy image of a layer of PCBM, a fullerene used in solar cells first synthesized at UC Santa Barbara by Fred Wudl, with (small) and without (large) the nucleating agent. The small domains form in the presence of the nucleating agent, demonstrating the new ability to control the size of crystallites of PCBM.

|

|

“We have developed a new method to utilize low-cost, environmentally friendly materials from the commodity chemical industry to control the performance of organic semiconductors,” said Michael Chabinyc, associate professor of materials.

|

|

Organic semiconductors are electronic materials with conductive properties similar to the familiar silicon-based material used in devices such as photovoltaics and computer chips, but with carbon-based structures. Pioneered at UCSB by Nobel laureate Alan Heeger, professor of physics and materials, and Fred Wudl, professor of chemistry and biochemistry and of materials, these semiconductors are useful for printable thin film electronics, such as light-emitting diodes, transistors, and solar cells.

|

|

Several challenges still exist in the emerging field of organic electronics, due in large part to their microstructure and crystallinity, the qualities of which can change with the method of their fabrication. The variations in these properties, in turn, can affect the materials’ electrical performance. While solution-based processes such as inkjet printing and blade coating can allow for inexpensive manufacturing, control over the microstructure must be maintained and at times the result is substantial variation in performance.

|

|

“The electrical properties of organic semiconductors depend critically on the way in which molecules pack together—the crystallinity. Gaining ways to control the crystallinity simply broadens the range of options for manufacturing,” Chabinyc said.

|

|

With the addition of minute amounts of nucleating agents, additives more commonly used in items like clear plastic drinking cups to maintain flexibility and to enhance their transparency, the researchers were able to demonstrate a method that offers more control over the formation of the organic semiconductors’ microstructures while at the same time increasing yield without sacrificing their performance. In addition to the sugar-based additive, the researchers tested another organic nucleating agent with a more complex structure.

|

|

“In one case we showed how the nucleating agents can improve the yield of printed transistors from essentially zero percent without the agents, to nearly 100 percent with those agents,” said Chabinyc. By adding these nucleating agents to triisopropyl-silylethynyl (TIPS) pentacene — a molecular semiconductor used to make printable transistors for flexible flat panel displays — the transistors could be produced successfully in high yields by inkjet printing. Without the agent, according to the study, it is difficult to form continuous films.

|

|

The research has significant implications for the future of organic semiconductors.

|

|

“Our work provides a pathway to aid in the further commercialization of these important materials,” said Chabinyc.

|