| Sep 19, 2018 |

Surfaces a key element in robotic fingers

|

|

(Nanowerk News) Picking up a pen off a desk and writing with it might seem easy to you, but it’s no small feat to a robot.

|

|

For one thing, once you pick up the pen, you then have to shift it in your hand to get it in the writing position. “You move the pen from an initial grasp to something more stable, but to do that, you’re gripping it with certain surfaces of the fingers and sliding it against other surfaces of the fingers,” said Adam Spiers, a former associate research scientist in Aaron Dollar’s lab. “It’s really quite complicated as far as all the force and frictional interactions go, but we all take it for granted as a very simple thing to do.”

|

|

So Dollar’s lab tried a simpler tack that focuses on the variation in friction of finger surfaces. Their results were recently published in IEEE Robotics and Automation Letters ("Variable-Friction Finger Surfaces to Enable Within-Hand Manipulation via Gripping and Sliding") and will also be presented at the International Conference on Intelligent Robots and Systems (IROS 2018).

|

|

|

“I think one of the key features of human hands that’s often overlooked is the surface properties of our fingers and what that allows us to do as far as moving objects within the hand,” Spiers said. “For example, when you make a light touch with your finger pads they are able to slide over objects, while using a bit more force deforms the soft internal tissue and causes them to grip.”

|

|

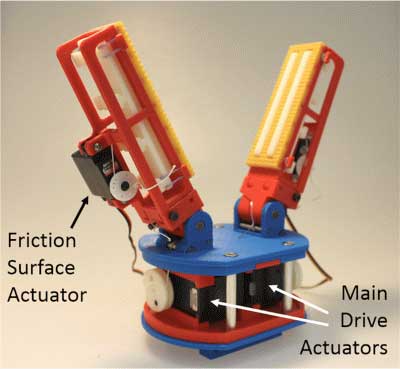

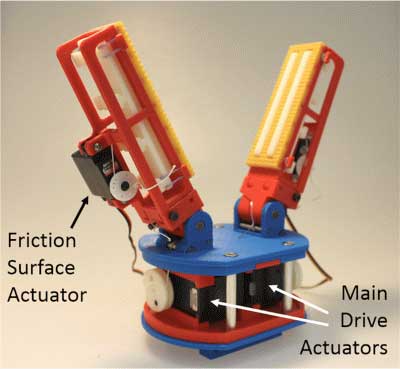

The newly developed ‘Variable Friction’ robot fingers combine a surface made of soft urethane (high-surface friction), a surface made of hard 3D-printed plastic (low-surface friction) and some rubber bands to suspend one surface behind the other. Two of these mechanical fingers face each other to form a robot hand, each with pivot joints at the bottom moved by electrical motors that allow the fingers to be controlled in multiple ways. At low-grip forces, the urethane acts as the finger pad, but switches to the hard surface made from Acrylonitrile Butadiene Styrene (ABS) at higher forces.

|

|

“We can get some pretty interesting behaviors where we can move objects within the hand, while they are being grasped,” said Spiers, now a research scientist at the Max Planck Institute for Intelligent Systems. “The object can be made to slide up and down the fingers, or we can make objects roll between the fingers. Then, we can actually combine those motions to reposition objects anywhere within the workspace of the hand.”

|

|

It’s kind of like a human hand, but not entirely.

|

|

“There’s a lot to be said for taking inspiration from nature, but not copying it too much,” he said. “With a human finger, you’re getting very good behaviors out of it, but it’s also attached to a really powerful brain.”

|

|

The origins of the intuitive way that humans can effortlessly perform complicated tasks is unclear, Spiers said. Is it because we have sophisticated brains that allow us to control our bodies with complex maneuvers, or because our fingers have a structure that includes the ability to vary surface friction?

|

|

In either case, he said, he sought to replicate the end results with the robotic device. It’s a proof-of-concept, so it still doesn’t perform some of the more subtle tasks that a human hand does, but they’ve made the design open-source so that other researchers could expand on it, and increase its dexterity.

|

|

“This is a new platform that other people can now build on and maybe implement those more difficult but common behaviors that humans do effortlessly but robots struggle with,” he said.

|