| Posted: Aug 09, 2012 | |

Making graphene 'bread' - leavening technique results in freestanding graphene oxide films |

|

| (Nanowerk Spotlight) Integration of graphene sheets and its functional derivatives into three-dimensional (3D) macroscopic structures is drawing much attention since it is an essential step to explore the advanced properties of individual graphene sheets for practical applications, such as chemical filters and electrodes for energy storage devices. | |

| However, a major problem in scaling up production of graphene is the tendency of individual graphene sheets to aggregate due to strong van der Waals attraction. Restacking of sheets not only reduces their solution processability, but also compromises their properties such as accessible surface area. | |

| Researchers are therefore working on strategies that prevent aggregation of graphene sheets in macroscopic structures so that the properties of the individual graphene sheets are not compromised and a number of strategies for preventing aggregation have been developed. They include adding "spacers" – i.e. surfactants, nanoparticles, polymers – or template-assistance growth. One such strategy we reported on last year was the crumpling the graphene sheets into balls (see our Nanowerk Spotlight: "Crumpled graphene balls for high surface area applications"). | |

| Alternatively, several groups have reported the formation of free-standing 3D graphene-based macroscopic structures without the assistance of any spacers for templates. However, preparing free-standing, flexible and multifunctional graphene films without complicated processing but with large accessible surface area by overcoming the aggregation of graphene sheets remains a challenge. | |

| Another novel approach, just reported, uses a simple leavening strategy – involving hydrazine vapor – to prepare reduced graphene oxide (rGO) foams with porous and continuous cross-linked structures from freestanding compact graphene oxide layered films. The whole process is more like making graphene "bread". The rGO foams perform excellently as flexible electrode materials for supercapacitors and selective organic absorbents. | |

|

|

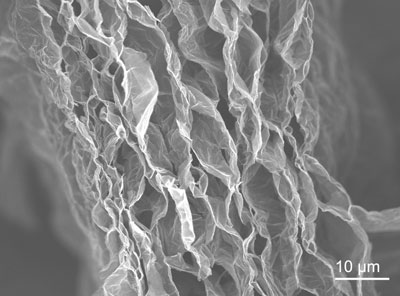

| Cross-sectional SEM images of rGO foam. (Image: Dr. Chen, Nanyang University) | |

| The research team, led by Xiaodong Chen, an assistant professor in the School of Materials Science & Engineering at Nanyang Technological University, has published their findings in the August 8, 2012 issue of Advanced Materials ("A Leavening Strategy to Prepare Reduced Graphene Oxide Foams"). | |

| "It is known that leavening is the process of adding gas to produce lighter, more easily chewable bread with the porous structures from compact dough before or during baking or steaming," Chen explains to Nanowerk. "Inspired by this, we thought that leavening could be an effective approach to transform compact graphene structures into porous structures if we could find a suitable 'leavening' procedure." | |

| In an earlier work, using vacuum filtration method, Ruoff and coworkers have successfully prepared graphene oxide (GO) compact layered films (see paper in Nature: "Preparation and characterization of graphene oxide paper") which could be regarded as "dough". | |

| "It is known that graphene oxide is rather unstable and can be chemically reduced under mild heating to yield reduced GO and gaseous species such as H2O and CO2," says Chen. "Therefore, if the gas released during chemical reduction of GO – like the leavening procedure to add gas – can be incorporated into compact GO layered films, porous graphene structures, i.e. rGO foams, just like "leavened bread" could be formed." | |

| In their experiments, the researchers prepared freestanding GO layered films which they suspended above a reservoir of hydrazine monohydrate inside an autoclave. Leavening and steaming of the graphene sheets for 10 hours at 90°C creates paper-like, lightweight, and electrically conductive rGO foams with open porous and continuously crosslinked structures. | |

| "Thermal steaming of GO layered films with hydrazine appears to be the key to the formation of rGO foams" says Chen. "The role of the hydrazine vapor here is to initiate the chemical reduction of GO to rGO with the rapid evolution of gaseous species." | |

| He notes that, compared to regular rGO layered films, rGO foams show greatly improved performance as flexible electrode materials for supercapacitors and selective organic absorbents. The rGO foams not only overcome the self-agglomeration of graphene sheets without spacer, but also achieve better contacts and lower sheet resistance. | |

| "The ease of fabrication and enhanced performance could make porous rGO foams a general and effective template for designing high performance energy storage or environmental remediation materials," says Chen. "Because of high conductivity and large accessible surface area, the free-standing and flexible rGO foams can be used for flexible supercapacitors as both the electrodes and current collectors, leading to a simplified and lightweight architecture." | |

| The calculated specific capacitance of the resulting rGO foam supercapacitor is about 110 F g-1. The hydrophobicity and superwetting behavior for organic solvents in combination with good capillary action makes rGO foam an excellent candidate for selective superabsorbance. As the research team points out, the uptake capacities of rGO foams are up to 37 times its weight for a collection of motor oil and up to about 26 times for organic solvents. These results clearly show the potential application of rGO foam in electrodes of supercapacitors and selective absorption. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|