| Posted: Jan 28, 2013 | |

Nanotechnology sensors for the detection of trace explosives |

|

| (Nanowerk Spotlight) In recent years, spread of terrorism has assumed an alarming proportion across the globe, emphasizing the need for sensitive and reliable detection of concealed explosives, leading to research on new, advanced technologies to protect the human life and property. Trace detection of explosives generally involves the collection of vapour or particulate samples and analyzing them using a sensitive sensor system. | |

| Various factors, such as wide variety of compounds that can be used as explosives, the vast number of deployment means and the lack of inexpensive sensors providing both high sensitivity and selectivity have made trace detection a very complex and costly task. High sensitivity and selectivity, along with the availability of low-cost sensors, is essential to combat explosives-based terrorism. | |

| Nanosensors have the potential to satisfy all the requirements for an effective platform for the trace detection of explosives. | |

| Detection of Explosives | |

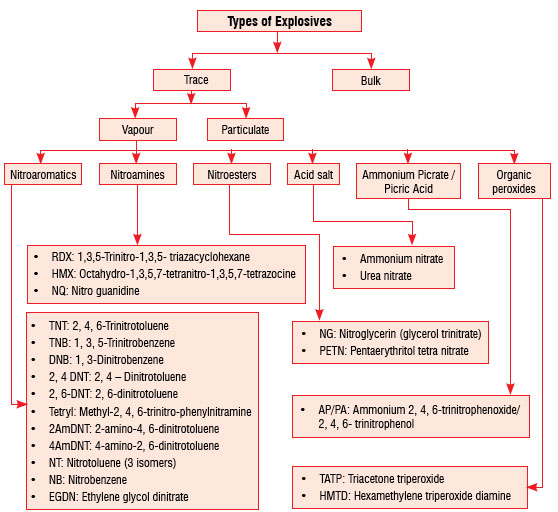

| Explosives are chemical-based compounds, which, on being initiated to undergo self-propagating decay, result in a sudden release of heat and pressure. Based on the burn rates, they are classified as low or high intensity explosives. Figure 1 shows the most commonly used explosives, classified into six broad classes. | |

|

|

| Fig. 1: List of commonly used explosives1. | |

| Nitroaromatic compounds comprise an important class of explosive compounds for detection due to their widespread use. Due to the low volatility of explosives, absorptive materials such as polymers have been employed as explosive vapour sensors, with a variety of transduction schemes. While monitoring these vapours, they accumulate over the sensing element of the detectors through either condensation or trapping of the analyte inside the pores. Once a certain mass threshold of vapours has been achieved, depending on the type of analyte present, detection occurs. | |

| Sensing of these volatile components depends heavily on the ambient temperature and humidity. These common explosives have extremely low vapour pressures at ambient temperature, which makes the molecules extremely sticky and get adsorbed very easily to the surfaces. An explosive with low vapour pressure has low volatility, or likelihood to exist in vapour form. Figure 2 shows the vapour pressures of explosives that tend to increase rapidly with temperature. Metals and their oxides have high surface energy and hence tend to have higher adsorption on their surfaces. At room temperature, condensation due to the stickiness of molecules, along with low vapour pressure in the sensor system, makes tracing difficult. The low volatility of explosives, coupled with their tendency to adhere to surfaces, makes direct trace particle detection an attractive alternative to vapour detection. | |

| Nanotechnology-enabled Technologies for Explosives Detection | |

| Nanotechnology-enabled sensors offer significant advantages over conventional sensors. This may be in terms of better sensitivity and selectivity, lower production costs, reduced power consumption as well as improved stability. The unique properties of nanoscale materials, such as increased surface area, confinement effects, etc., make them ideal for sensing. Nanomaterials can be integrated into existing sensing technologies or can be used to develop new devices. Various types of sensors, such as physical sensors, electro-sensors, chemical sensors and biosensors, have greatly benefitted from nanotechnology. | |

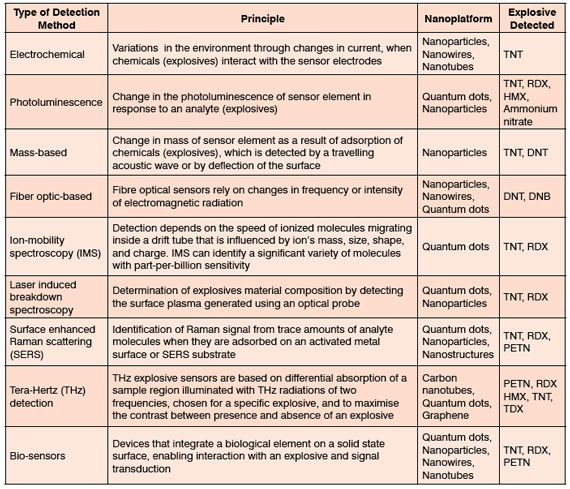

| Explosives sensors are broadly categorised into electrochemical, mass, optical and biosensors depending on the type of measurement. Spectrophotometric methods that are used for detecting explosives include photoluminescence, fluorescence, laser-induced breakdown spectroscopy and Tera-Hertz spectroscopy. | |

| Currently, different nanotechnology-enabled techniques exist for detecting trace explosives using these methods. A large number of nanosensor platforms such as micro- and nanofabricated structures, quantum dots, nanowires, nanotubes, nanobelts, etc. are being used for sensing explosives. Various approaches for trace explosives detection and platforms to function as nanosensors for chemical and biological compounds including explosives have been experimentally demonstrated by various R&D studies in the area of nanomaterials as listed in Table 1. | |

|

|

| Table 1: Different Techniques for the Detection of Various Explosives using Nanotechnology2. | |

| Challenges in Moving Towards Practical Application | |

| The first part of the challenge is to develop a sensor that is both sensitive and selective. The second part, which is more difficult, is to bring explosives near the sensor element. Trace explosives detection by nanosensors practically requires integrating the nanosensor elements into a system that includes vapour collection and pre-concentration abilities. Extremely low vapour pressures limit the number of explosives molecules to be collected in a reasonable detection time. In addition, the concentration of explosives decreases exponentially as a function of distance from the source. Very low concentrations of explosive molecules increase false positives and hence effective techniques are much needed for sample collection and pre-concentration in developing practical sensor systems. | |

| Recent R&D Activities and Breakthroughs in Nano-based Sensors for Trace Explosives Detection | |

| In view of tremendous potential for nano-enabled sensors for trace detection of explosives, intense R&D activities have been undertaken throughout the world in various establishments. A few recent R&D activities on nanotechnology-enabled detection of explosives are listed below: | |

| Receptor-based Trace Explosives Detection | |

| Receptor-based sensing achieves selectivity by the specific interaction between the receptor molecule and the explosive analyte, which leads to change in a measurable property such as mass, conductivity or absorbance, which is then used to compute the interaction. A number of coatings can be used for imparting partial selectivity, including self-assembled monolayers (SAMs), polymers, metal oxides, single-stranded DNA, etc. | |

| The SAM of 4-mercaptobenzoic acid (4-MBA), commonly known as thiosalicylic acid, has been demonstrated as a partially selective coating for explosives3. Thiosalicylic acid provides carboxyl end groups for acid?base reactions with the explosive molecules. These groups immobilized on silver (Au) coated nanosensor surfaces strongly bind with the basic groups of nitro-substituted molecules of explosive vapours. | |

| Zuo et al.4 recently reported the use of 6-mercaptonicotinic acid (6-MNA) monolayers for increasing the sensitivity of TNT detection. The obtained data shows that the sensor has well defined response to TNT vapour concentration as low as 0.1 ppb (100 ppt). McCluskey and co-researchers from the University of Newcastle, Australia, have demonstrated the use of molecularly imprinted polymers (MIPs) for obtaining chemical speciation.5 | |

| Interaction of functional monomers, explosive molecule templates and a cross-linking agent is responsible for the generation of MIPs for explosives. MIPs that is very specific for TNT have been developed and demonstrated by the above team. | |

| Nanomechanical Sensor Platform | |

| Nanomechanical effects induced by molecular adsorption offer exceptional opportunities for trace explosive detection. Nanomechanical sensors such as cantilever beams operate on the change in resonance frequency of a cantilever beam due to mass adsorption. In other words, the binding of explosive molecules with the detection molecules on the cantilever made of nano-structured silicon will induce a surface stress. | |

| Cantilevers with very low resonance frequency showed high sensitivity of mass sensing at the zeptogram scale (1x 10-16g) for bending-mode operation7. | |

| Electronic Nose Approach | |

| The reversible receptors for explosives are not very selective and hence can be used in an array format for creating a response pattern. This approach is similar to an artificial olfaction system. Ultrasmall devices such as electronic noses with high sensing capabilities form viable technological platforms for trace explosive detection6. | |

| Electronic nose devices are usually composed of 1) a chemical sensing system comprising an array of sensors with each senor containing nanostructures of carbon nanotube, nanowires, etc. for high-sensitivity detection of a particular target vapour or molecular adsorption, 2) a sampling system and 3) a pattern recognition system, such as an artificial neural network. The response from the arrays is generally analyzed using pattern recognition algorithms for identifying a single chemical with certainty. The outputs from the sensor array are thus combined to form a fingerprint or signature, which is unique for a particular explosive. | |

| Bio-inspired Nanostructured Sensor for the Detection of Ultra-low Concentrations of Explosives | |

| Micromechanical sensors based on micro-cantilevers with piezoresistive or optical signal detection have recently opened new perspectives for the detection of different chemicals. Inspired by the structure of the sensing system of silk moth, researchers from French?German Research Institute of Saint-Louis, have developed a method using a silica microcantiliver9 modified with ordered three-dimensional vertically aligned titania nanotube (TiO2-NT) for ultra-low detection of TNT. | |

| The possibility of using these nanostructured micro-cantilevers to detect explosives was tested by generating pulses of TNT vapour in a controlled manner by placing TNT microcrystals on a nanocalorimeter chip below a microcantiliver and heating to 47°C. The detection threshold of the sensor was found to be below 1 ppt. The excellent reversibility and repeatability of the adsorption-desorption process observed prove that TNT strongly interacts with the surface of the TiO2 NTs. | |

| Nanosensor for TNT Detection Based on Molecularly Imprinted Polymers and Surface-Enhanced Raman Scattering | |

| A new strategy has been developed by researchers at United States Army Research Laboratory, (RDRL) for detecting 2, 4, 6-trinitrotoluene (TNT) that integrates molecularly imprinted polymers (MIPs) with surface enhanced Raman scattering (SERS)10. Thin films of sol gel-derived xerogels of micron thickness were deposited on a SERS-active surface as the sensing layer. Xerogels were then molecularly imprinted for TNT using non-covalent interactions with the polymer matrix. When TNT binds with the polymer matrix, it results in unique SERS bands that allow for detection and identification of the molecule in the MIP. | |

| Hybrid Nanosensor for TNT Vapour Detection | |

| Real-time detection of trace explosives in a complex environment containing various interferents has been a difficult challenge. | |

| Researchers from Arizona State Univ., USA have described a hybrid nanosensor based on the electrochemical reduction of TNT and the interaction of the reduction products with conducting polymer nanojunctions in an ionic liquid11. | |

| The change in electrochemical current resulting from the reduction of TNT and the conductance change of the polymer nanojunctions are simultaneously measured by the sensor. This hybrid detection mechanism with unique selective preconcentration capability of the ionic liquid provides a selective, fast, and sensitive detection of ∼6 ppt level of TNT. | |

| New Sensor Developed By MIT can Detect Tiny Traces of Explosives with Single Molecule Resolution | |

| MIT researchers have created a new sensitive detector capable of detecting a single molecule of TNT12. They have coated carbon nanotubes (SWNTs) with protein fragments called bombolitins found in bee venom. Each nanotube-peptide combination reacts differently to different nitro-aromatic compounds. By using different nanotubes coated with different bombolitins, the researchers were able to identify unique "fingerprints" for the detection of different explosives. Variants of bombolitins class of amphipathic bee-venom derived peptides undergo a unique sequence-dependent conformational change upon binding, resulting in a specific analyte response involving wavelength shifting of the single-wall nanotubes fluorescence emission. | |

| The induced wavelength shift permits fingerprinting of the analyte via analysis of the response of different SWNT species. Further encapsulation of SWNTs with single stranded DNA (ss(AT)15) enabled selective detection of TNT with single molecule resolution. | |

| R&D Prototypes and Commercialized Sensors | |

| Studies on various nanoplatforms for different types of explosives being detected have lead to prototype development, eventually leading to commercialisation of nanosensors with enhanced selectivity and sensitivity. | |

| A Cantilever-based electronic nose for explosive detection | |

| The Centre for Excellence in Nanoelectronics (CEN), IIT Bombay, Mumbai, has demonstrated a nano device for TNT and RDX explosives detection13. The device is extremely sensitive and uses a low-cost piezoresistive polymer cantilever. The sensitivity is down to levels. These nanodetection devices are meant for vapour phase detection of explosives molecules and have integrated wireless transmission capability. Chemical reaction on the surface of the cantilever generates surface stress, which in turn results in the deflection of the cantilever. The cantilever surface can be regenerated after detection for subsequent measurements. The present low-cost technology is particularly suitable for remote sensing. This technology has been exclusively licensed to Nanosniff Technologies Pvt. Ltd., a company incubated at IIT Bombay. | |

| Wireless nanotechnology sensor for explosives detection | |

| Researchers at the Georgia Institute of Technology, USA, have developed a prototype wireless sensor capable of detecting trace amounts of a key ingredient found in many explosives, particularly improvised explosive devices (IEDs)14. The device employs carbon nanotubes and is printed on paper or paper-like material using standard inkjet technology. This prototype incorporates a chemical sensor and a communications device in a small, low-cost package and represents a significant step towards producing an integrated wireless system for explosives to be operated almost anywhere. | |

| Nanotechnology-based electronic sensor for detecting explosives with performance better than sniffer dogs | |

| Researchers at Tel Aviv University (TAU), Israel, have developed a powerful electronic sensor making use of arrays of silicon nanowires coated with an electron-rich amino-silane (APTES) compound that binds to explosives to form an electronic nanotransistor and is able to detect many kinds of dangerous chemicals15. In order to further enhance the chip?s sensitivity, researchers have developed each chip with around 200 individual sensors that work in tandem to detect different kinds of explosives with high degree of reliability, efficiency and speed. This nanotechnology-based sensor is fast and highly portable and is more sensitive with detection capability for TNT down to a detection limit of ∼0.1 femtomolar (~1x10-6 ppt), which is more reliable than sniffer dogs. | |

| Nanomaterial ink that can detect and neutralize explosives | |

| Researchers at Oklahoma State University, USA, have developed and successfully tested a spray-on material that both detects and neutralizes explosives16. The material is a type of ink made of nanoparticles of a compound of molybdenum, which changes colour from dark blue to pale yellow or colourless in the presence of explosives. This feature makes the nanoparticles work as a sensor for the quick detection of vapours produced by explosives. This feature can also serve as an explosives neutralizer. Researchers claim that spraying the ink onto bombs or suspicious packages and watching the color change will indicate the level of threat from the devices. In order to neutralize the suspected devices, they can be dumped into large containers of the ink. When used as an electronic sensor, this highly sensitive material is capable of detecting triacetone triperoxide (TATP) vapours at levels as low as a 50 ppm within 30s. | |

| Product: Reference 660 Cartridge Reader | |

| Description: The R660 instrument is comprised of three major components: Detection Cartridge, Cartridge Reader and Processing Unit. | |

| Key Features: | |

|

|

|

| Company: SpectraFluidics (USA) | |

| Product: Falcon First Responder Kit | |

| Description: Falcon First Responder Kit is a field-deployable, self-contained explosives detection and evidence collection kit providing two testing methods for detecting explosive residue on any surface. Its core detection capability is powered by Raptor?s patented SAFE-T? nanotechnology. | |

| Key Features: | |

|

|

|

| Company: Wheatley SPI LLC (USA) | |

| Product: Quantum Sniffer™ QS-H150 Portable Explosives Detector | |

| Description: The Quantum Sniffer™ QS-H150 employs a patented vortex collector for simultaneous detection of explosives particulates and vapors with or without physical contact and in real-time. | |

| Key Features: | |

|

|

|

| Company: Implant Sciences Corporation (USA) | |

| Conclusions | |

| Nanotechnology can be exploited to develop sensors that satisfy the requirements for trace explosive detection. Recent advances in nanomaterials have shown the potential in developing sensors for explosive detection at single molecule level. Due to their reduced size, nano-enabled sensors can be incorporated into multiple arrays on single substrate, making it useful for detecting various threats simultaneously a paving way for their successful implementation and commercialization. The direct impact of nano-enabled sensors is clearly visible with companies taking advantage of this technology to develop sensors for the trace detection of various explosives. | |

| References | |

| 1. www.epa.gov/esd/tsc/images/fld-smpl.pdf | |

| 2. L.A. Pinnaduwage, V. Boiadjiev, J. E. Hawk et al., Appl. Phys. Lett., 83 (2003) 1471 | |

| 3. K.A. Singh, ?Nanosensors For Explosive Detection?, ObservatoryNano, Institute of Nanotechnology, U.K. (2009) | |

| 4. G. Zuo, L. Xinxin, Z. Zhixiang, et al., Nanotechnology, 18 (2007) 255501-255508 | |

| 5. A. McCluskey, I.C. Holdsworth, C.B. Michael, et al., Org. Biomol. Chem., 5 (2007) 3233-3244 | |

| 6. http://www.observatorynano.eu/project/catalogue/B/2/536ko/ | |

| 7. Y.T. Yang, C. Callegari, X.L. Feng, et al., Nano Lett., 6 (4) (2006) 583-586 | |

| 8. L. Senesac and T.G. Tundat Materials today, 11(3) 2008 28-36 | |

| 9. D. Spitzer, T. Cottineau, N. Piazzon, et al., Angew. Chem. Int. Ed., 51(2012) 5334-5338 | |

| 10. www.dtic.mil/cgi-bin/GetTRDoc?AD=ADA516676 | |

| 11. A.D. Aguilar, E.S. Forzani, M. Leright, et al., Nano Lett., 10(2) (2010) 380-384 | |

| 12. A. H.Daniel, W.P George, J. Zhang, et al., Proc. Natl. Acad. Sci, USA, 108 (2011) 8544?8549 | |

| 13. http://www.ee.iitb.ac.in/~nanoe/research.html | |

| 14. http://www.nano.gatech.edu/news/release.php?id=5562 | |

| 15. http://chemistry.tau.ac.il/patolsky/index.php?option=com_content&view=article&id=51&Itemid=51 | |

| 16. http://www.sciencedaily.com/releases/2011/03/110331191514.htm | |

| Contributed by K. Madhuri, [email protected], CKMNT, Hyderabad, India. | |

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|