| Posted: Oct 03, 2013 | |

On demand nanofin heat sinks for computer chips (w/video) |

|

| (Nanowerk Spotlight) Heat has become one of the most critical issues in computer and semiconductor design: The ever increasing number of transistors in computer chips requires more efficient cooling approaches for the hot spots which are generated as a result of the operation of the transistors. | |

| To reduce high temperatures, today's microchips are fitted with heat sinks – finned devices made of conductive metal such as aluminum or copper – that are attached to the back of the chips to pull thermal energy away from the microprocessor and transfer it into the surrounding air. However, the ever-increasing transistor packing density in microchips, which is associated with more hot spots, is pushing the limits of such traditional cooling systems and researchers therefore have been experimenting with alternative cooling concepts (see for instance our previous Nanowerk Spotlight: "Cooling computer chips with interface-enhanced carbon nanotubes"). | |

| Researchers at RMIT University in Australia have now demonstrated a microfluidic technique of using thermally conductive and magnetic nanoparticles that can form low-dimensional fins in the vicinity of hot spots. They report their findings in the September 23, 2013, online edition of Advanced Energy Materials ("Dynamic Nanofin Heat Sinks"). This work is the first ever report on using nanoparticles for making nanofins on demand in microfluidics. | |

|

|

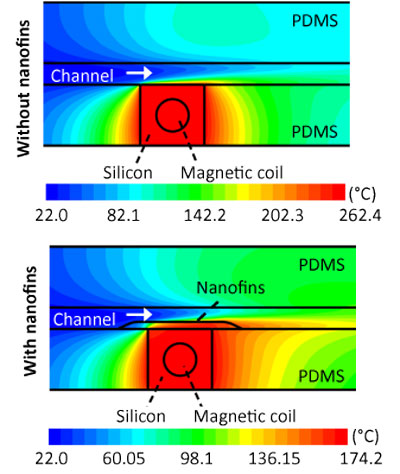

| The microfluidic platform without and with nanofins. (Image: Prof. Kalantar-zadeh, RMIT University) | |

| "People have used nanoparticles in microfluidics to increase the thermal conductivity of liquid," Kourosh Kalantar-zadeh, a professor in the School of Electrical and Computer Engineering at RMIT University, tells Nanowerk. "However, there are limitations. The concentration of nanoparticles cannot exceed 2-3% of the total weight of the liquid/particle mixture or else it clogs the channel. Using our method, we increase the concentration of nanoparticles only near the hot spots and form the desired nanofins, while the overall concentration of nanoparticles in the microfluidic can be as small as 0.01%." | |

| Basically, what the team did was create "nanofins on demand". They used ferromagnetic chromium oxide (CrO2) nanoparticles and moved and placed them around hot spots by exerting a magnetic force. | |

| "We disperse these nanoparticles in microfluidics that are formed around the IC chips and we can establish nanofins from them on demand," explains Pyshar Yi, a PhD candidate in Kalantar-zadeh 's group and first author of the paper. "These nanofin structures are thermally conductive, and absorb the generated heat from the hot spots. They do two things in their operation: They release heat efficiently into the flow of liquid around them; and they can also be released on demand to take the heat with them and release them somewhere else." | |

| The nanoparticles were needle-shaped with a length of 100-400 nm and a diameter of 20-50 nm. They form spire shape bundles of nanoparticles – the nanofins – perpendicular to the side wall surface near the magnetic coil. After exposure to a magnetic field, the nanoparticles grew to a length of about 320 µm during the first 5 minutes. When the magnetic field is switched off, the thickness of the layer reduces to just less than 100 µm in less than 1.5 minutes. | |

| This video shows the formation of nanofins from CrO2 magnetic nanoparticles in 10 min, compressed into 19 seconds. (Video: Prof. Kalantar-zadeh, RMIT University) | |

| "Our work is a proof of concept and the performance of the systems should be improved," says Dr. Khashayar Khoshmanesh, who co-first-authored the paper with Yi. "Higher flow rates, while maintaining the high aspect ratio nanofin structure, is the key to increase the efficiency and with more advanced designs this can be achieved." | |

| The researchers note that, while the most important application of nanofins can be cooling IC chips, they can be used for other applications as well. "They are compatible with microelectronic industry processes and are small in size. So they can be implemented in many household cooling systems ranging from mobile handsets to even large cooling apparatus. They can be used in many domestic and military applications and even for cooling wearable jackets." | |

| She also points out that other types of forces, such as electric and mechanical, can also be used in forming nanofin structures. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|