| Posted: Dec 17, 2007 | |

Ultrathin transparent graphene films as alternative to metal oxide electrodes |

|

| (Nanowerk Spotlight) As a critical component of optoelectronic devices, transparent conductive coatings pervade modern technology. The most widely used standard coating is indium tin oxide (ITO), used in nearly all flat panel displays and microdisplays. Causing problems for manufacturers, though, Indium is expensive and scarce and demand is increasing. | |

| From the depressed levels of $60/kg in 2002, indium prices rose to over $1,000/kg during the summer of this year. Recently, prices have fallen back to between $400-$500/kg. But, geologists say the cost of indium may not matter soon, because the earth's supply of this element could be gone within just a few years. | |

| In addition to the limited availability of Indium there are other reasons that make ITO and other metal oxides such as FTO (fluorine tin oxide) increasingly problematic for electronics manufacturers: the instability of these metal oxides in the presence of acid or base; their susceptibility to ion diffusion into polymer layers; their limited transparency in the near-infrared region; and lastly, the current leakage of FTO devices caused by FTO structure defects. This has made the search for novel transparent electrode materials with good stability, high transparency and excellent conductivity a crucial goal for optoelectronic researchers. | |

| Recent work by researchers in Germany exploits ultra-thin transparent conductive graphene films as window electrodes in solar cells. | |

| There has been quite a buzz about graphene – discovered only in 2004 – a flat, one-atom thick sheet of carbon. This rising star in material science, exhibits remarkable electronic properties that qualify it for applications in future optoelectronic devices. We have written about graphene in a Nanowerk Spotlight a few months ago (Nanotechnology researchers go ballistic over graphene). | |

| "Transparent and conductive graphene-based composites have already been prepared by incorporation of graphene sheets into polystyrene or silica" Dr. Linjie Zhi explains to Nanowerk. "However, the conductivity of these transparent composites is low, which makes the composites incapable of serving as window electrodes in optoelectronic devices. In contrast, we have developed a simple approach for the fabrication of conductive, transparent, and ultrathin graphene films from exfoliated graphite oxide, followed by thermal reduction. The obtained graphene films with a thickness of ca. 10 nm exhibit a high conductivity, comparable to that of polycrystalline graphite, and a transparency of more than 70% over 1000-3000 nm." | |

| Zhi, a researcher in Prof. Klaus Müllen's Synthetic Chemistry research group at the Max Planck Institute for Polymer Research in Mainz/Germany, together with Xuan Wang and Müllen, successfully demonstrated the application of graphene films as window electrodes in solid-state dyesensitized solar cells. Their work has been reported in the December 11, 2007 online edition of Nano Letters ("Transparent, Conductive Graphene Electrodes for Dye-Sensitized Solar Cells"). | |

| The graphene films can be prepared via either top-down exfoliation of graphite oxide flakes followed by thermal reduction, or bottom-up construction of extremely large PAHs, nanographene molecules followed by thermal fusion. | |

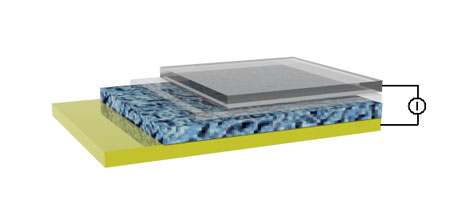

| To demonstrate how the transparent graphene films are potential window electrodes for optoelectronics the Max-Planck scientists fabricated a dyesensitized solid solar cell using the graphene film as anode and gold as cathode. | |

|

|

| Illustration and performance of solar cell based on graphene electrodes. Shown is the dye-sensitized solar cell using graphene film as electrode, the four layers from bottom to top are gold, dye-sensitized heterojunction, compact titanium dioxide, and graphene film. (Image: Dr. Zhi/Max Planck Institute for Polymer Research) | |

| Zhi notes that, in contrast to ITO, the graphene electrode shows an outstanding thermal and chemical stability besides its high transparency and good conductivity. Furthermore, simple processing enables inexpensive and large-scale industrial manufacturing. That is the reason why the concept of using graphene electrodes is emerging as a very practicable option for future optoelectronic devices. | |

| "The unique properties of the as-obtained graphene film include high conductivity, good transparency in both the visible and near infrared regions, ultra-smooth surface with tunable wettability, and high chemical and thermal stabilities, render the graphene-based window electrodes versatile for applications not only in solar cells described in our recent work, but also in fabrication of flat panel displays, organic light-emitting diodes (OLEDs), and other modern optoelectronic devices" says Zhi. | |

| Zhi points out that the concept of using transparent, conductive graphene films as window electrodes in solar cells works well, however, in a non-optimized state. | |

| "The graphene-based solar cells show a relatively lower efficiency than metal oxide coating based solar cells" he says. "There is still large room for improvement of the device performance by, for example, further increasing the conductivity of the graphene films via the use of large graphene sheets with lateral dimensions on the micrometer scale, or exploitation of a new and special structure of solar cells based on graphene window electrodes. Of course, we also face a number of challenges going forward, such as perfection of the graphene structure; a balance of conductivity and transparency of the graphene film; fabrication techniques for graphene-based optoelectronics, just to name a few. Nevertheless, we believe this is a new starting point in the direction of graphene window electrodes, which may open a door for further development of novel optoelectronics." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|