| Posted: Mar 20, 2018 | |

Nanoengineered bioinks for 3D printing |

|

| (Nanowerk Spotlight) Imagine being able to print out healthy tissue with just a sample of a patient's own cells. While printed replacement human body parts might seem like science fiction, the use of 3D printing technologies for medical applications is a relatively new but rapidly expanding research field, although still quite a way from clinical application for treating patients. | |

| Currently, two of the biggest problems facing three-dimensional (3D) bioprinting are that bioinks – a jelly-like substance consisting mostly of water – don't print with anywhere near the performance of other 3D printed materials; and they aren't strong enough at cell-friendly concentrations. In other words, currently available bioinks cannot 3D print self-sustaining anatomic-size structures containing live cells. | |

| Another major challenge that bioinks present is their complexity. It's clear that simple polymer solutions that were initially tried are not meeting all of the requirements of bioinks, so more and more researchers are looking into state-of-the-art material science techniques to give bioinks a boost. | |

| It looks like 3D bioprinting is developing into a very multidisciplinary field that is going to require scientists to become knowledgeable outside their main field, including biology as well as materials science and chemistry, in order to develop advances. | |

| However, not all tissue engineering labs have the necessary chemistry and materials science expertise and support to replicate the more complex designs that are coming out, which is part of the reason why researchers at Texas A&M University stuck to inexpensive and widely available ingredients to create a novel bioink. | |

| To overcome the limitations of existing bioinks, they report the development of a highly printable bioink for fabricating large scale, cell-laden, bioactive scaffolds. | |

| "We have achieved these improvements through a novel bioink strengthening strategy that combines nanocomposite reinforcement with ionic-covalent entanglement (ICE) to create a bioactive nanoengineered ionic-covalent entanglement (NICE) bioink with excellent printability, mechanical properties, and shape fidelity," Akhilesh K. Gaharwar, an Assistant Professor at Texas A&M University, tells Nanowerk. | |

| The team, led by Gaharwar, has published their findings in ACS Applied Materials & Interfaces ("Nanoengineered Ionic-Covalent Entanglement (NICE) Bioinks for 3D Bioprinting") | |

|

|

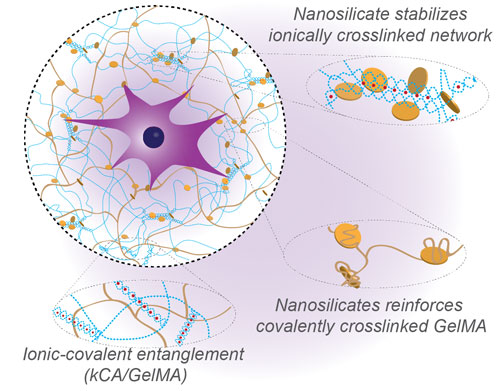

| Nanoengineered ionic-covalent entanglement (NICE) bioink. The NICE bioinks use nanosilicates to reinforce an ionic-covalent entanglement hydrogel made from GelMA and κCA, creating a dually reinforced hydrogel network. These interactions allow the NICE bioink to behave as a solid at low shear stresses and improve shear thinning characteristics during bioprinting. After cross-linking, ICE and nanosilicate reinforcement synergistically improve mechanical strength. (Image: Inspired Nanomaterials and Tissue Engineering (iNanoTE) Lab, Texas A&M University) (click on image to enlarge) | |

| The core finding of this work is that it is possible to combine two very different hydrogel reinforcement techniques to obtain synergistic reinforcement and improved printability without sacrificing the cell-friendly nature of the hydrogel. | |

| While nanocomposite reinforcements and dual crosslinked polymer blends (ICEs) have both been investigated separately for improving mechanical properties of hydrogels, they have never been applied simultaneously to a bioink for tissue engineering or bioprinting applications. | |

| And it turns out that the combination (NICE) is even more effective than the sum of its individual parts. From a mechanical perspective, this is notable because conventional bioinks had to increase crosslinking density to gain mechanical strength, to a point that that was damaging to cell in the ink. | |

| In contrast, the unique characteristics of the NICE bioink is its ability to 3D print larger, taller tissue structures that are tough and resilient, while keeping the embedded cells alive during the printing process. | |

| The high structural fidelity and mechanical stiffness of the bioprinted structures using NICE bioinks could be used as custom implants. In addition, 3D bioprinted structures from NICE bioink can be used to understand cancer progression as well as drug testing. | |

|

|

| Top left: The NICE bioinks print freestanding hydrogel structures with a high aspect-ratios and high print fidelity. Top right: The cross-linked structures are stiff and elastomeric, and can support more than 50-times their own weight. Bottom left: The 3D printed structures from NICE bioink have high structural fidelity (as demonstrated with this 3D printed ear). Bottom right: The encapsulated cells aligning parallel to 3D printed NICE scaffold structures after 30 days in culture and show high survival rates. (Image: Inspired Nanomaterials and Tissue Engineering (iNanoTE) Lab, Texas A&M University) | |

| "As a nanomaterials lab, we were already working with nanoengineered hydrogels, so we asked ourselves if there was anything more we could do to improve strength even further," notes Gaharwar. "That was when we started experimenting with combining nanoparticles reinforcement into ionic-covalent entanglement hydrogels." | |

| The group's earlier work has already shown that nanosilicates can improve hydrogel printing because they are shear-thinning, which makes inks flow more smoothly (ACS Nano, "Bioactive Nanoengineered Hydrogels for Bone Tissue Engineering: A Growth-Factor-Free Approach" and "Shear-Thinning and Thermo-Reversible Nanoengineered Inks for 3D Bioprinting"). These nanosilicates are disc-shaped, mineral nanoparticles 30-50 nm in diameter and about 1 nm thick. | |

| "Nanosilicate interactions can improve stiffness, elasticity, adhesiveness viscoelastic modulus, and cell adhesion in some hydrogels, and imbue hydrogel solutions with complex fluid behavior that can improve bioprintability," explains David Chimene, a graduate student in Gaharwar's group and the paper's first author. "Furthermore, Laponite® nanosilicates have shown broad biocompatibility in vivo and in vitro, and are used extensively in cosmetics and toothpastes as well as in drug delivery and tissue engineering." The group had previously reported their work on synthesizing colloidal bioinks composed of Laponite® (Langmuir, Nanoengineered Colloidal Inks for 3D Bioprinting). | |

| The team is now moving on to testing their bioink in animals to obtain a much clearer picture of how NICE bioinks interact with living tissue. | |

| "We will be able answer questions on how quickly cells from adjoining tissue can infiltrate within the bioprinted structure," notes Chimene. "While all of the materials in this NICE formulation are biocompatible, we need to evaluate how this specific formulation interacts with the body to be able to fine-tune degradation rate in order to maximize tissue regeneration." | |

| As the scientists gain data from animal experiments they will be able to create specific compositions for regenerating different tissue types. This will include customizing the amounts of different components in order to match target mechanical properties and incorporating drug and biomarker delivery into the structures to better control cell behavior. | |

| There are some challenges, though. For one, covalent crosslinking in bioinks is most often done using photoinitiators and UV light. This setup has been streamlined to require only a small application of UV-A (365nm) light, and most reported research has not shown any obvious effects on cells. Nevertheless, it is a concern that UV light might still be damaging cells in minor ways, so there is certainly a need to find safer photoinitiators for bioinks. | |

| For the ink itself, its thermosensitivity, which is crucial to its printability, can be a challenge to work with as the ink must be kept slightly above room temperature during printing. It took the team some doing to find a way to reliably keep the ink from gelling in the printer tip and causing clogs. They are currently designing new printer tips that make this much simpler to manage. | |

| "We are hoping that our work can be used as a springboard for researchers who want to develop their own accurate 3D reconstructions of human tissue parts," concludes Gaharwar. "Accurate and cell-friendly structures can be used in a wide range of biomedical research, including tissue engineering as well as drug design, disease progression, and cancer therapy." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|