| Posted: Apr 30, 2018 | |

Nanopatterning holograms onto commercial contact lenses |

|

| (Nanowerk Spotlight) The humble contact lens, widely used to correct common vision problems, is on its way to become a 'smart' diagnostic tool that brings self-powered wearable electronics right to your eyeball. | |

| Tears contain diagnostic information regarding ocular diseases, and they can be used as a surrogate medium for analyzing blood chemistry. One recent example is a graphene-based contact lens sensor for glaucoma diagnosis, another demonstration has been a glucose-sensing contact lens for diabetics to monitor their blood sugar levels. | |

| In new work, researchers from the University of Birmingham report in ACS Nano ("Direct Laser Writing of Nanophotonic Structures on Contact Lenses") a method to produce optical nanostructures onto contact lenses. | |

| This method aids in functionalizing and nanotexturing an off-the-shelf, commercial contact lens. | |

|

|

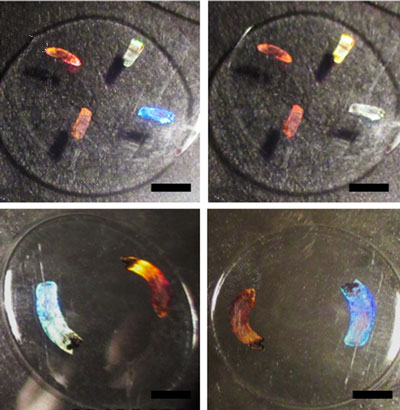

| Different designs of holographic nanostructures fabricated on contact lenses. Each image demonstrates the diffraction colors observed at various angles (scale bar = 5 mm). (Reprinted with permission by American Chemical Society) | |

| "Integrating nanoscale features into commercial contact lenses for application in low-cost biosensors has been a challenge so far," Dr. Haider Butt, Senior Lecturer of Micro Engineering and Nanotechnology at the School of Engineering, University of Birmingham, tells Nanowerk. "With our new method we have been able to print holograms on contact lenses in a single step by using lasers. The method is very simple, inexpensive, does not require clean room environment and can be used for printing nanostructures (surface holograms) on any commercially available contact lens. In effect we are making wearable holograms." | |

| "Already, various nanostructures have been fabricated within hydrogels that act as optical transducers," he adds. "However, integrating nanoscale features into hydrogel structures represents a fundamental challenge for producing functional contact lenses. Most nanofabrication approaches to form optical structures in polymers are costly and time-consuming." | |

| Previously used methods such as nanoimprinting (via UV exposure) involve multiple process steps and are not compatible with all commercial silicon-hydrogel contact lenses. | |

| In contrast, the method of producing nanostructures on a soft, fragile and thin hydrogel based surface demonstrated by Butt and his team is fast and requires only a single step. | |

| "Other groups doing similar research use in-house produced contact lenses, with materials and geometries different from the ones commercially sold," notes Butt. "In our work, we used commercial contact lenses and functionalized their surface to covert them into a sensing device." | |

| The researchers developed a holographic laser ablation method to produce optical nanostructures. They used a black dye on the contact lens to facilitate the interaction between the interfering laser beams and the lens material. | |

| "With our method, we can rapidly create low-cost optical nanostructures by direct laser interference patterning (DLIP) in holographic Denisyuk reflection mode to create ablative interference fringes on the contact lens surfaces," explains Butt. "The holographic DLIP system enables us to produce different types of nanopatterns on the soft and fragile surfaces of the lens." | |

| He notes that the contact lens material (silicon-hydrogel), which is not purely solid at ambient humidity conditions, withstood up to three laser pulses without significant damage to its relatively thin matrix. | |

| The team fabricated the optical nanostructures at the edge of the contact lens in order to prevent any sight obstruction or interference of vision. | |

| The nanopatterns can be designed in various shapes and could be used for sensing as well as cosmetic purposes. However, the primary use for this kind of nanotextured lenses will be in sensing and monitoring eye-related disorders like glaucoma and dry eyes. | |

| For instance, tears contain a lot of biomarkers that provide information regarding the workings of the body; with these contact lens holograms, various eye related disorders can be monitored. The team is also working towards using the holograms for monitoring eye pressure for glaucoma patients. | |

| Going forward, the scientists are interested in producing more sophisticated nanopatterns on the contact lenses. At the moment, they create two-dimensional nanopatterns, which display a rainbow like hologram effect. In future, they want to pattern 3D nanostructures on commercial contact lenses for more sophisticated functionalities. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|