| Jan 17, 2019 | |

Graphene researchers are inspired by spider webs |

|

| (Nanowerk Spotlight) Highly flexible and sensitive strain sensors are essential components of wearable electronic devices and graphene's piezoresistive effect, combined with its other properties such as ultra-translucency, superior mechanical flexibility and stability, high restorability, and carrier mobility, make it a very promising material for fabricating high-sensitivity strain sensors. | |

| Potential application areas for these sensors could be found in flexible display technology, robotics, smart clothing, electronic skin, body monitoring, human-machine interfaces, in vitro diagnostics, and implantable devices. | |

| Already, researchers have demonstrated examples of highly sensitive graphene strain sensors, for instance for wearable wireless musical instruments or as dual-function sensors and switches. | |

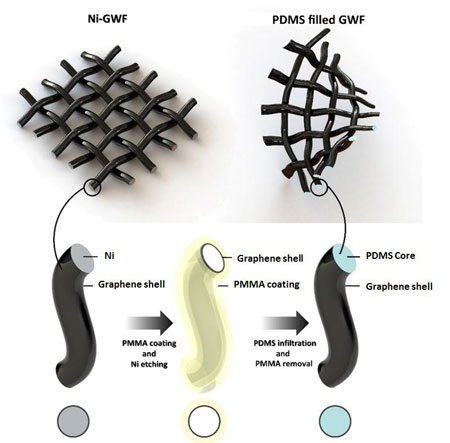

| Motivated by the high level of flexibility exhibited by spider webs, scientists in Hong Kong have developed a novel design for highly flexible and sensitive piezoresistive sensors based on an elastomer-filled graphene-woven fabric (E-GWF) structure. This technique mimics the distinct core-shell structure of spider webs. This fabrication method could also be extended to other 1D and 2D materials for many emerging practical applications. | |

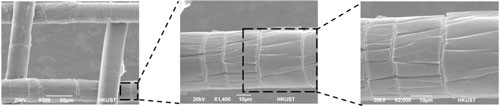

| As the team from The Hong Kong University of Science and Technology reports in ACS Applied Materials & Interfaces ("Spider-Web-Inspired Stretchable Graphene Woven Fabric for Highly Sensitive, Transparent, Wearable Strain Sensors"), in addition to excellent sensing capability, the E-GWF also shows unusual switching behavior at large strains owing to the reversible cracking and reconnection of interconnected graphene tubes. | |

|

|

| Schematic flowchart of the fabrication procedure of an E-GWF. (Reprinted with permission by American Chemical Society) | |

| "The combination of high sensitivity, flexibility, and stretchability makes the spider-web like wearable strain sensor suitable for mounting on the human skin," Qingbin Zheng, a Research Assistant Professor of Mechanical and Aerospace Engineering, tells Nanowerk. "In addition, the semitransparent strain sensor can improve user experience without any significant impact on daily activities." | |

| Furthermore, the developed spider-web-like wearable strain sensor can strengthen interactions between humans and smart systems, especially in shape-conforming systems of electronic skin, elastic displays, epidermal sensors, personalized health monitoring and human-machine interfaces. These sensors should be able to maintain good functionality when conformably in contact with human skin/muscle with curvilinear surfaces. | |

| Researchers and material scientists have long been fascinated by spider silk – ultra-strong and extensible self-assembling biopolymers that outperform the mechanical characteristics of many man-made materials, including steel. | |

| As Zheng and his co-authors describe in their paper, a spider web is built with silk whose structure consists of a bundle of silk fibrils, known as spidroin, which are encapsulated by about 100-200 nm thick outer layers made up by lipids, glyco, and skin. The core is 2-3 µm thick and dominates the tensile strength and elasticity. The molecular structure of silk consists of regions of protein crystals separated by less-organized protein chains. The primary structural modules give rise to diverse secondary structures that, in turn, determine the functions of different silks. | |

| Inspired by this unique architecture, the researchers developed their design for a highly flexible and sensitive piezoresistive sensor, which mimics the geometric and functional characteristics of a spider web. | |

|

|

| Magnified SEM images of the freestanding E-GWF sensor taken at 20% tensile strain. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| "It was proposed previously that there are three critical components that need to be considered when designing new functional materials, including the chemical composition, nano/microstructure, and architecture," Zheng explains. "The design of our E-GWF involves using graphene/PDMS as the main constituent to ensure high flexibility; nanoscale graphene/PDMS microfibers as the nano- and microstructural framework to provide high sensitivity; and woven fabric as the assembled architecture to guarantee structural integrity." | |

| "These three components make E-GWFs an ideal bio-inspired hierarchical material for strain sensors arising from the multiscale structures spanning from woven fabric, PDMS microfiber to nanoscale graphene," he adds. | |

| Although the working range of the sensor has been increased up to 20% durable strain, a much higher stretchability is required for full-range human motion monitoring, such as at the joints of the human body. The team expects that additional structural engineering such pre-straining, wrinkling and patterning will enable them to increase the sensors' stretchability significantly. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|