| May 17, 2019 | |

'Stitching' together ultrastrong graphene films |

|

| (Nanowerk Spotlight) Graphene's outstanding mechanical and electrical properties make it a very attractive material for applications in aerospace and flexible electronics. This, however, requires the assembly of graphene into macroscopic graphene nanocomposites. | |

| High-performance graphene films have many promising applications as lightweight structural materials for a variety of uses, from in aircraft and automobile bodies to windmill blades and sports equipment; as flexible conductive materials for increasingly popular portable and wearable electronics; and as electromagnetic (EM) interference shielding materials for eliminating the EM pollution of diverse electronic devices. | |

| Introducing graphene sheets into a polymer matrix through solution mixing, melt mixing, and in situ polymerization are common processes used to make graphene nanocomposites. However, these methods usually result in nanocomposite films with poor mechanical and electrical properties due to the low content of graphene, poor dispersion, and weak interfaces between graphene and polymer matrix. These disadvantages severely limit these nanocomposites’ practical applications. | |

| Researchers in China have reported a novel strategy to 'stitch' reduced graphene oxide (rGO) nanosheets into ultra-strong, super tough, and highly conductive graphene films using only small amounts of cross-linker. They show that the bridging of long-chain π-π bonding agent between neighboring rGO nanosheets can provide substantial improvement in multiple properties including tensile strength, toughness, electrical conductivity, EMI shielding capability, and resistance to mechanical damage. | |

| They report their findings in Matter ("Ultrastrong Graphene Films via Long-Chain π-Bridging"). | |

|

|

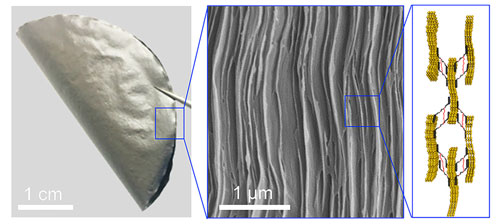

| Left: Photograph of π-bridged rGO film displaying its flexibility. Middle: High-resolution SEM image of the fracture surface of the film. Right: Illustration of the long-chain π-bridging. (© CellPress) | |

| "Our graphene films not only demonstrate a record tensile strength of almost 1.1 GPa, but exceptional abilities to absorb mechanical energy, transport charge, and shield electromagnetic interference that are comparable to or even superior to graphene films annealed at much higher temperatures," Qunfeng Cheng, a professor at Beihang University in Beijing, tells Nanowerk. "Our process uses abundant natural graphite as a raw material at room temperature. This novel strategy can provide an inspiration for converting low-priced graphite powders into much higher performance macroscopic graphene films for diverse commercial uses in the future." | |

| For this work, the researchers were inspired by the layered structure, sophisticated interface architecture, and growth at ambient temperature of nacre (mother-of-pearl), the pearly internal layer of many mollusc shells. Nacre is one of the best examples of an exceptionally tough natural material that exhibits structural robustness, despite the brittle nature of their ceramic constituents. | |

| Cheng notes that numerous high-performance graphene-based nanocomposites have been demonstrated through various interface design strategies in the past. "However, these graphene-based nanocomposites usually show only moderately enhanced mechanical properties at the expense of decreased electrical conductivity due to the addition of insulating cross-linkers, impeding their practical applications," he adds. | |

| In their work, the team demonstrates that long-chain π-bridging can simultaneously enhance the tensile strength, toughness, and electrical conductivity of graphene films. They found that less than 7 wt% content of π-π bonding agent (polymerized BPDD) delivered the best performance results. The resulting films have record values compared with the previously reported graphene-based nanocomposites bridged by various interface interactions under ambient conditions. | |

| Cheng points out that, compared with other interface design strategies, long-chain π-bridging can not only provide highly efficient stress transfer and large slippage space for graphene nanosheets, but also induce alignment of graphene nanosheets, resulting in remarkable electrical conductivity comparable to that of high-temperature annealed graphene films. | |

| These integrated high-performance graphene films could find numerous applications, for instance as structural materials in place of carbon fiber composites in aerospace or for other functional materials in electromagnetic interference shielding, popular portable devices, and wearable electronics. | |

| The team's strategy of assembling ultra-strong graphene films through long-chain π-bridging could also inspire an avenue for the assembly of graphene nanosheets and other nanoscale building blocks into high-performance macroscopic nanocomposites using various cross-linkers. | |

| "In addition," says Cheng, "the strengthening and toughening mechanisms can also give us impetus to overcome the conflict of attaining strength and toughness, two properties that are often mutually exclusive, in structural materials and traditional composites." | |

| There are two key scientific problems to be solved to further improve the performance of graphene films. First, the researchers will endeavor to develop a large-scale manufacturing technique to allow the integration of this bridging strategy into commercial applications. Second, they will continue to develop higher performance graphene films incorporating interface bridging and structure optimization for uses in extreme environments, such as ultrahigh or ultralow temperature. | |

| The properties of the team's graphene films are still lower than those of the single-layer graphene nanosheet, so they will continue their search for solutions to further enhance the tensile strength, toughness, and electrical conductivity of macroscale graphene films for many applications. | |

| In addition, although these graphene films show high performance at room temperature, their performance in extreme environments, such as outer space with intense radiation, and frequent variations of high and low temperatures, needs to be investigated. | |

| "One main challenge might be how to precisely design interface interactions between adjacent microscale graphene nanosheets to achieve a tensile strength higher than current carbon fiber-reinforced nanocomposites," Cheng concludes. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|