| Jul 31, 2019 | |

How to turn every piece of clothing into an e-textile |

|

| (Nanowerk Spotlight) By embedding ultrathin, flexible and (ideally transparent) sensors, actuators, electronics and nanogenerators into textiles it becomes possible to develop a new generation of self-powered e-textiles where the electronic components are all but invisible (for more, read our collection of Nanowerk Spotlights on various aspects of wearable electronics). The resulting smart clothing, smart medical attachments, data gloves and other human-machine interfaces will herald a new era of wearable electronics. | |

| However, the electronic components in e-textiles are prone to short-circuits, rust, and mechanical degradation due to the natural flexibility and tendency of natural fibers (such as cotton of wool) to absorb moisture from the environment or the user. This moisture not only damages textile-based electronics but contributes to bacterial proliferation, making the textile smelly and uncomfortable to wear. Not to mention the problems caused by putting e-textiles into washing machines... | |

| Thanks to new work coming out of Purdue University, it is now possible to fabricate textiles that can protect you from rain, stains, and bacteria, while they harvest the biomechanical energy of the user to power textile-based electronics. | |

| These self-powered e-textiles also constitute an important advancement in the development of wearable machine-human interfaces, which now can be washed many times in a conventional washing machine without apparent degradation. | |

| The research team, led by Ramses Martinez, an Assistant Professor leading the FlexiLab at Purdue's Weldon School of Biomedical Engineering, has published their findings in Advanced Functional Materials ("Waterproof, Breathable, and Antibacterial Self-Powered e-Textiles Based on Omniphobic Triboelectric Nanogenerators"). | |

|

|

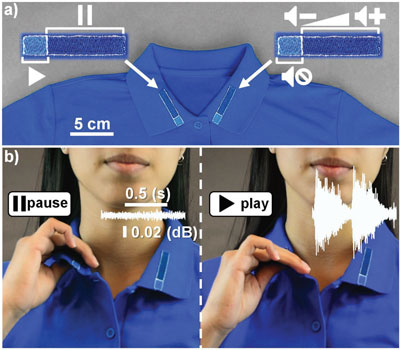

| Self-powered audio control interface based on triboelectric nanogenerators embroidered on the neck of a polo shirt. (Image: FlexiLab, Purdue University) | |

| "We render textiles omniphobic – repellent to oils, water, and dust – using fluorinated molecules that do not change the mechanical properties or 'touch' of the textile," Martinez explains to Nanowerk. "By combining embroidery with the spray-based deposition of fluoroalkylated organosilanes and highly networked nanoflakes, we create omniphobic triboelectric nanogenerators that can be incorporated into any fiber-based textile and be used to power wearable devices using energy harvested from human motion." | |

| Triboelectric nanogenerators (TENGs) are capable of harvesting electrostatic energy from a variety of human body motions in order to power wearable electronic devices. The omniphobic nanogenerators (RF-TENGs) fabricated by the Purdue team are breathable, flexible, and resistant to bending, stretching, and washing, making them ideal candidates to power e-textiles and to serve as human-machine interfaces for the wearer. | |

| They also designed their nanogenerators with large-scale fabrication runs in mind, using embroidery as a technique compatible with conventional textile manufacturing techniques. | |

| "Thanks to this invention, textile companies can embed flexible circuits in the clothes they manufacture and avoid including heavy rigid batteries to power them, making the textiles compatible with standard machine washing," Martinez points out. "Our RF-TENGs are thin, flexible, breathable, inexpensive to fabricate (less than $0.04 cm-2), and capable of producing a high power density (600 µW cm-2). E-textiles based on RF-TENGs repel water, stains, and bacterial growth, and show excellent stability under mechanical deformations and remarkable washing durability under standard machine-washing tests." | |

|

|

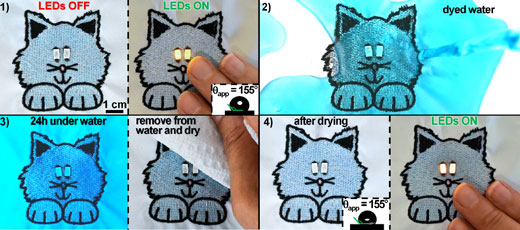

| Stability of RF-TENGs to prolonged immersion in water. 1) Energy harvesting by an RF-TENG before immersion in water. Inset shows an apparent static contact angle of ∼155° with water. 2) RF-TENG being submerged in blue-dyed water. 3) RF-TENG is kept immersed in water for 24 hours, and then removed from the water and quickly dried with a paper towel. 4) After drying the RF-TENG, there is no significant change in its static contact angle or its energy-harvesting performance. (Reprinted with permission by Wiley-VCH Verlag) (click on image to enlarge) | |

| To fabricate and integrate the RF-TENGs into textiles, the researchers used commercially available cotton, spandex, and wool fabrics. These were spray-coated with conductive silver nanoflakes, a layer of polytetrafluoroethylene (PTFE) to encapsulate this electrode, and silanizing agents (fluoroalkylated organosilanes) in order to make them oliophobic and conductive. They then embroidered designs on top of this bottom electrode layer with conductive sewing thread to integrate the RF-TENGs into the textile, securing the embedded electronics. In a final step, the embroidered designs were also rendered omniphobic by spray-coating them as well. | |

| The RF-TENGs operate in vertical contact? separation mode, generating energy when the motion of the wearer induces the compression, bending, or rubbing of the device. The repetitive separation and recontact of the textile layer of the top electrode and the PTFE coating of the bottom electrode generates charges on their surfaces due to the triboelectric effect. | |

| Tapping – i.e. applying pressure to – the nanogenerator embroidery generates an electric charge that can be stored in a capacitor. The team demonstrated various design using different RF-TENG sizes and capacitors with different capacitances, for example an audio control strip as shown in the video below. | |

| Triboelectric textile interfaces. RF TENG audio control interface embroidered on an omniphobic polo shirt. The audio player, embedded in the textile, is powered using the biomechanical energy harvested from the wearer using the RF TENGs on the sides of the polo shirt. (Video: FlexiLab, Purdue University) | |

| The researchers have filed a provisional patent application and they are engaged in active conversations about how to integrate this technology to hospital gowns in order to provide better care for the patients. | |

| "One thing that strikes me is the fact that, while fashion has evolved significantly during the last centuries and has easily adopted recently developed high-performance materials, there are very few examples of clothing on the market that interact with the user," Martinez concludes. "Having a battery-free, e-textile interface controlled by the wearer sounds like the most convenient approach for seamless communication with machines and the Internet of Things; that is why my team wanted to explore the possibility of augmenting the capability of any type of clothing item using RF-TENGs." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|