| Oct 04, 2019 | |

Graphene transistor catches mycotoxins in food |

|

| (Nanowerk Spotlight) Among the number of foodborne diseases caused by different pathogens the toxin impurities produced by different fungi and moulds (called mycotoxin) are considered as nonavoidable contamination for any food. Thus, there has been introduced a daily tolerance level that is considered 'acceptable'. | |

| Nonetheless, these toxins can become overconcentrated (due to failure storage conditions) in the body, causing health problems including neurodegenerative diseases and cancer. Most mycotoxins are also stable even towards heat treatment and fermentation process. | |

| Currently, chromatography is the most widely accepted and most accurate method of detection of mycotoxins in food, yet the measurements are slow and require laboratory environment for proper sampling. Yet the development of portable sensors for portable point-of-use testing is still challenging. | |

| A team of researchers from Biosense Institute (Serbia), University of Texas at Austin (USA) and National Research University of Electronic Technology (Russia), has developed a method for direct, in-field detection of mycotoxins in food. | |

| The method is based on the modification of electrolyte operated graphene field effect transistors that have been specifically functionalized with aptamers by covalent binding. | |

|

|

| Image shows chip containing the array of graphene transistors in the set-up to toxins measurements. (Image: Biosense Institute) | |

| In fact, the type of construction based on graphene covalently modified with aptamers as a channel in field effect transistors is widely used in different pathogen detection techniques due to the robust and relatively simple assembly of sensing layers. Now it has been demonstrated that this method can be used for detection of such small molecules as toxins. | |

| The research team has reported their findings in Toxins ("Graphene-Based Sensing Platform for On-Chip Ochratoxin A Detection"). | |

| The scientists demonstrated the performance of this method on Ochratoxin A by specific aptamer modified graphene field effect transistors. The graphene channel area was only 20 micrometres wide. The overall size of the chip is 1 cm2 ta facilitate the array of graphene transistors and the electrode patterns for connecting to the measurement setup. | |

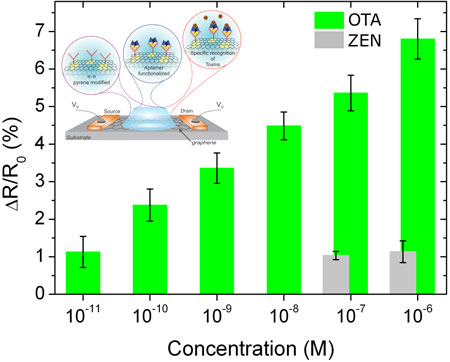

| These sensors have shown a response time of within 5 minutes with a sensitivity down to 4 pg/ml – that is about three orders of magnitude less than accepted tolerance levels of Ochratoxin A. | |

| Moreover, the team demonstrated that these sensors can be easily regenerated in urea solution within several seconds while preserving the performance. That makes these sensors highly attractive for repeated usage. They need only a single drop of the sample (about 30 microliters) to detect the toxins. | |

| This work, lead by I. Bobrinetskiy, has demonstrated real sample performance with wine spiked with Ochratoxin A, showing performance comparable to that of laboratory testing. The team made the observation that properties of the liquid matrix can effect sensor performance, perhaps due to different pH values of the liquids. Further real-life field experiments are required to identify the exact cause. | |

|

|

| The sensitivity of sensor to ochratoxin A (OTA, green) and its selectivity in comparison to zearalenone (ZEN, gray). The insert top left shows the scheme of sensor operation. (Image: Biosense Institute) (click on image to enlarge) | |

| This study takes a first step towards the development of integrated graphene-based toxin sensors produced by a conventional microelectronic technological process. The selectivity of the sensors can be tuned by changing the type of aptamer used, while the fabrication on silicon substrate provides the possibility of integrating read-out devices to transfer information, e.g. to a mobile phone. | |

| Furthermore, it is of paramount importance to demonstrate the performance for other types of toxins, e.g. cyanotoxins produced by certain bacteria and algae living in fresh water. The increasing number of observed cyanobacterial blooms in different natural freshwater lakes and manmade reservoirs makes the development of accurate sensor networks for toxin control a priority for safe freshwater supply. | |

| The main benefit of such ultra-small sensors-on-a-chip is that they can be made in arrays of transistors with different aptamer attached for multiplex sensing of variety of toxins in a single sample, paving the way for on-site development of integrated portable devices. | |

| This project was funded in part by European Union's Horizon 2020 research for development of Centre of Excellence for Advanced Technologies in Sustainable Agriculture and Food Security (ANTARES). | |

|

A Nanowerk exclusive provided by National Research University of Electronic Technologye

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|