| Mar 25, 2020 | |

Bioprinting techniques advance from shape to function |

|

| (Nanowerk Spotlight) Biofabrication is a revolutionizing toolkit for regenerative medicine that allows cells and other biomaterials to be precisely combined and patterned into three-dimensional (3D) constructs through automated, cell-friendly fabrication methods. | |

| One of these methods is bioprinting, an additive 3D-printing method where tissue growth and the behavior of cells can be controlled and investigated by embedding them in a delicate 3D framework. | |

| 3D bioprinting is a highly-advanced manufacturing platform that allows for the printing of tissue, and eventually vital organs, from cells. This could open a new world of possibilities for the medical field, while directly benefiting patients who need replacement organs. | |

| In the early days of bioprinting, around 2013, the lack of printable materials that could serve as cell-laden bioinks, as well as the limitations of printing and assembly methods, presented major constraints for the usefulness of the technique. | |

| Things have changed since then. With rapid advanced in 3D-printing hardware on one hand and bioink materials on the other, biofabrication techniques have gained significant momentum and provide a powerful approach to tackle major hurdles in the generation of engineered living tissues. | |

| While 3D bioprinting is still in its early stages, the remarkable leap it has made in recent years points to the eventual reality of lab-grown, functional organs. | |

|

|

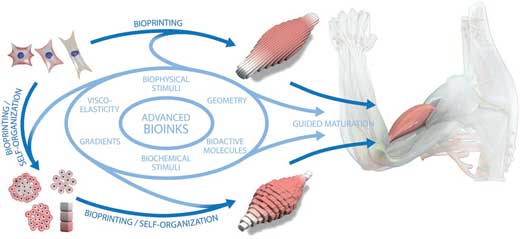

| Possible approaches toward the convergence of bioprinting and self-organization to guide the maturation of bioprinted constructs toward the generation of functional tissues. Inspired by the composition of adult, native tissues, multiple progenitor or differentiated cells can be loaded into bioinks to build tissues or organoids. In this approach, the architecture imposed by the printing process will be templating the cell-driven development of the tissue and its subsequent maturation. Alternatively, specific stem and progenitor cells that possess the ability to autonomously organize into submillimeter to millimeter organoids that exhibit salient tissue features can be used as intermediate building blocks and as bioink components. In both processes, the stimuli provided by the biomaterials, their architecture, and bioactive factors included in the bioinks play key roles for driving the acquisition of native functions. (Reprinted with permission by Wiley-VCH Verlag) (click on image to enlarge) | |

| Bioprinted structures are being designed and studied for a wide range of biomedical uses. For instance, researchers have demonstrated 3D-bioprinting of living structures with built-in chemical sensors or to create functional liver tissues. Other potential uses are transplantable grafts for tissue restoration; advanced in vitro models to aid the testing of drugs; and potential alternatives to animal experimentation. | |

| With regard to building materials in biofabrication processes, two different types of printable inks can generally be distinguished. One are biomaterial inks used to print cellular structures on which cells are seeded or that can also be used as surgical tools or implants after fabrication. Many different materials, including thermoplasts and metal powders, can be processed that way. The other types are bioinks – printable formulations that contain living cells. | |

| These two different types of inks have different,sometimes opposing printing requirements. The simultaneous need for these opposing requirements led to the conceptualization of the biofabrication window, the range of material properties suitable both for printability with high shape fidelity and for the support of cell function. | |

| In a recent review in Advanced Materials ("From Shape to Function: The Next Step in Bioprinting"), the authors summarize key strategies that have expanded the biofabrication window and that lead to improved control over shape. Building on such advances in material science, their main focus is on the current and future steps toward mimicking salient functionalities of living tissues, through the creation of hierarchically structured constructs, in particular when using bioinks as building blocks for extrusion-based bioprinting. | |

| The review discusses the impact of bioprinted constructs with preformed spatial organization to facilitate tissue morphogenesis. The authors highlight recent and upcoming developments in biofabrication that could influence the next generation of engineered tissues. | |

| They point out that the recent progress in hydrogel design together with the development of new bioprinting strategies, have introduced effective solutions to extend the biofabrication window, reducing the need to compromise on the use of materials that display satisfactory structural properties, but provide a nonoptimal environment for cells to thrive. | |

| Cell functionality is necessary both for in vitro models and to move forward toward the demonstration of applicability of bioprinted constructs as biomedical devices that can eventually be used as clinical solution to repair damaged tissues, and bring researchers a step closer toward the ambitious goal of functional bioprinting. | |

| Despite this remarkable progress, scientists are only beginning to tap into the potential of biofabrication in aiding the reconstruction of fully functional living engineered tissues. | |

| Finally, the authors urge that future strategies embrace biological (developmental) processes and integrate them with bioprinting technologies to yield constructs with biological function toward the ambitious goal of printing functional tissues or even entire organs. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|