| Oct 23, 2023 | |

Digital 3D printing advance enables on-demand custom microfluidics |

|

| (Nanowerk Spotlight) Microfluidics, the science of manipulating tiny amounts of fluid in micro-scale devices, has long held promise for revolutionizing fields like medical diagnostics, chemistry, and biology research. But the specialized manufacturing techniques traditionally required to produce microfluidic chips have limited their widespread use. | |

| Now, researchers at McGill University in Canada have leveraged recent advances in 3D printing to develop an integrated method to rapidly design and print fully functional microfluidic chips in under 30 minutes. | |

| Their advancements, reported in the journal Advanced Materials ("Digital Manufacturing of Functional Ready-to-Use Microfluidic Systems"), pave the way for on-demand, low-cost production of application-specific microfluidic devices even by those with no specialized manufacturing skills. | |

|

|

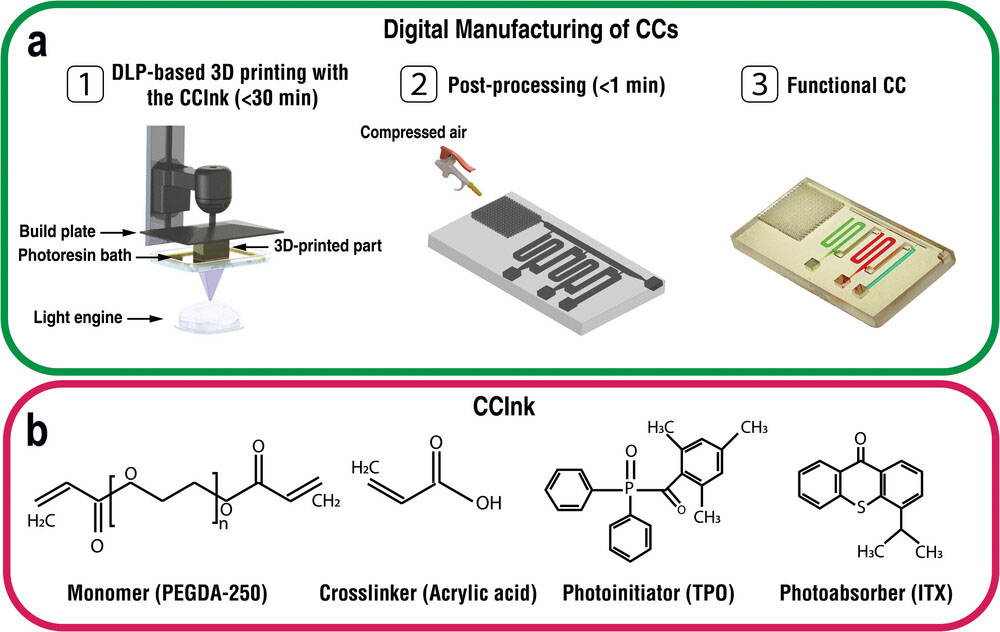

| Digital manufacturing (DM) of functional capillaric circuits (CCs) using an intrinsically hydrophilic ink (CCInk). a) 1) Additive manufacturing of CCs from a digital design file using a light engine and layer-by-layer vat photopolymerization. 2) Removal of uncured CCInk under a stream of compressed air (<1 min). 3) Functional CC loaded with reagents and primed to execute the structurally encoded (i.e., pre-programmed) capillary flow events following the addition of the triggering solution. b) CCInk composition including polyethyleneglycol diacrylate (PEGDA-250) monomer, acrylic acid (AA) additive to tune hydrophilicity, a photinitiator (TPO), and a photoadsorber (ITX). (Reprinted with permission by Wiley-VCH Verlag) | |

| Microfluidic chips, sometimes called lab-on-a-chip devices, miniaturize and automate complex laboratory workflows onto small plastic chips about the size of a USB stick. By shrinking experiments down, they use tiny sample and reagent volumes, speed up testing, and enable portability. But fabricating the microscopic channels and components that control fluids in these chips requires cleanroom microfabrication techniques not widely accessible to researchers and clinicians. | |

| In particular, application-specific microfluidic chips would benefit enormously from on-demand and on-the-fly design and manufacturing. This would allow researchers to optimize chips for specialized experiments and clinicians to develop customized point-of-care diagnostic devices. But the specialized facilities and skills traditionally needed to produce custom microfluidic chips have severely limited this potential. | |

| More recently, 3D printing has allowed simplified production of microfluidic chips. But existing 3D printable chip designs still depend on external control systems, limiting their plug-and-play functionality. And the insufficient resolution of common 3D printers restricts the tiny conduits and valves needed for handling fluids at the microscale. | |

| To overcome these limitations, the researchers developed an integrated 3D printing method using a custom ink formulation and design techniques to produce fully autonomous, monolithic microfluidic chips requiring no external control systems or assembly. | |

| The key was formulating a photocurable ink using an acrylic acid additive to permanently tune the ink’s hydrophilicity—its attraction to water. This allowed the material to spontaneously fill microscopic channels via capillary action while enabling flow control structures like valves. The researchers also optimized 3D printable valve geometries to reliably control fluids within fully enclosed channels. | |

| Leveraging these material and design advancements, the team 3D printed complex, multilayer microfluidic chips with networks of tiny circular conduits and integrated capillary pump structures. They demonstrated the capabilities of their printed chips by performing an automated three-step immunoassay to detect COVID-19 antibodies. | |

| The integrated method allows functional microfluidic chips to be 3D printed in under 30 minutes on widely accessible, commercial 3D printers costing just a few thousand dollars. According to the researchers, this could enable on-demand, distributed manufacturing of application-specific microfluidic devices by those without specialized skills and expands experimental possibilities for fields relying on microfluidics. | |

| With further development, the approach may allow researchers to simply download and print custom microfluidic chip designs from online repositories, facilitating sharing of experimental workflows. The technology could also expand access to diagnostic testing by enabling fast, on-site production of microfluidic chips even in resource limited settings. But realizing this potential will likely require further work on integrated sample handling and readout methods. | |

| By demonstrating a pathway to rapidly prototype and manufacture highly integrated microfluidic chips in ordinary lab settings, this advance brings the long-standing vision of democratized, application-specific microfluidics closer to reality. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|