| Nov 27, 2023 | |

Ultrasensitive multifunctional electronic skin mimics spider skin to enable resilient robotics |

|

| (Nanowerk Spotlight) Developing electronic sensor skins that can mimic the remarkable sensory capabilities of natural skin has proven extremely challenging. Past electronic skin attempts focused mainly on human-centered wearables, lacking the hardy resilience for applications in emerging fields like robotics and bio-integrated devices where exposure to extreme environments is inevitable. | |

| Significant barriers remain, including effectively patterning sensitive nanomaterials on durable substrates and minimizing signal interference from environmental factors like temperature fluctuations. Without solutions to these lingering technical roadblocks, truly adaptable multi-modal electronic skins suitable for robotics and biointegration remain out of reach. | |

| Recent materials science breakthroughs in conductive nanomaterials and stretchable substrates have brought the long-standing goal of versatile artificial sensor skins tantalizingly within reach. But substantial barriers remain, including effectively patterning sensitive nanomaterials on durable substrates and minimizing cross-sensitivity to simplify signal processing. Without solutions to these lingering technical roadblocks, truly adaptable multi-modal electronic skins suitable for robotics and biointegration remain out of reach. | |

| Drawing creative bio-inspiration from the crack-shaped sensory organs of spiders, an interdisciplinary research team spanning multiple Chinese institutions developed an innovative approach for manufacturing highly environmentally robust electronic skins with both extreme strain sensitivity and thermal sensing capability. | |

| The team reports their findings in Small ("Bioinspired Environment-Adaptable and Ultrasensitive Multifunctional Electronic Skin for Human Healthcare and Robotic Sensations"). | |

|

|

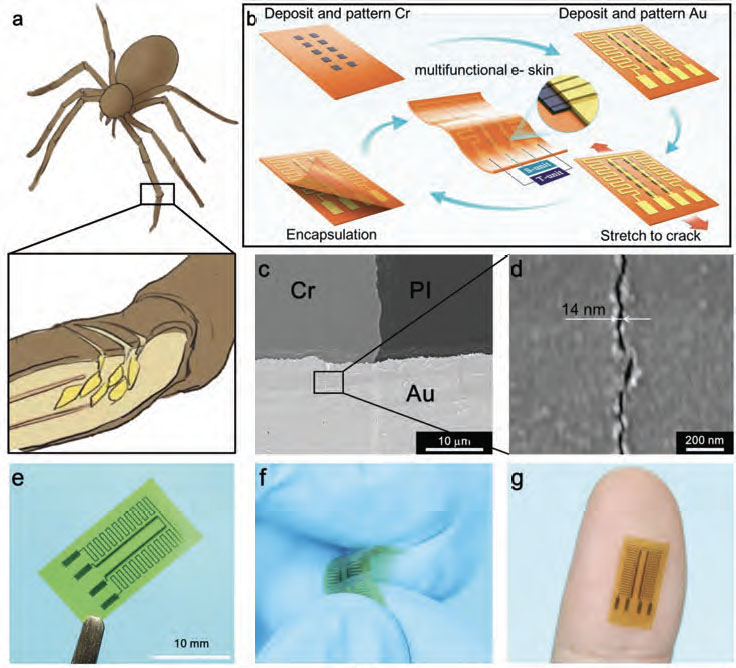

| The multifunctional e-skin manufactured by crack localized metal pattern. a) Schematic illustration of crack-shaped sensor organ of a spider. b) Schematic illustration of the fabrication process of the proposed multifunctional e-skin, in which, non-cracked serpentine-shaped Au film is used for temperature sensing (T-unit) and cracked strain Au electrode is used for strain sensing (S-unit), respectively. c) The SEM photos of the localized nanocrack pattern induced by the Cr layer. d) The width of the crack gap is 14 nm. e–g)The photo of e) the e-skin, f) under bending, and g) attached on a finger. (Reprinted with permission by Wiley-VCH Verlag) | |

| Leveraging recent advances in flexible circuit nanofabrication, the researchers devised an ingenious technique to induce nanoscale cracks in precise locations on metal films bonded to durable polyimide substrates. Mimicking the crack-based mechanoreceptors that enable spiders to sense faint vibrations on their webs, these intentional conductive cracks serve as ultrasensitive strain gauges. Meanwhile, the surrounding non-cracked gold film regions are designed in a serpentine layout optimized for thermal measurements only. | |

| This breakthrough technique enabled the researchers to integrate both modalities using the same robust polyimide substrate and conductive gold nanomaterial. With both sensing regions made of identical constituents, the thermal response from the non-cracked serpentine gold films can be cleanly subtracted from the strain sensing unit’s signal. By effectively decoupling temperature effects in this way, the strain sensory readings can maintain accuracy even when exposed to drastic environmental temperature swings from -20 °C to 250 °C. | |

| Leveraging polyimide’s intrinsic resilience to high temperatures and caustic solutions, the team’s electronic skins maintained full functionality when submerged in settings as harsh as boiling acids. And despite the extreme durability, the strain sensing modules preserved acute precision with gauge factors over 80 times greater than natural skin. This extraordinary combination of hardiness and sensitivity surpasses all existing electronic skins and opens up applications far beyond fragile human-centric wearables. | |

| To validate performance for both emerging application domains of wearable wellness monitors and resilient robotics, the researchers conducted proof-of-concept demonstrations spanning muscle activity tracking, soft grasping enhancement, and underwater maneuvering. Measurements remained accurate across diverse thermal environments from frigid sub-zero icy seawater to scorching hot plates. | |

| By effectively addressing the core challenges of maximizing ruggedness and stretchability while minimizing thermal signal interference, this breakthrough research provides the foundational building blocks for the next generation of bio-integrated devices and adaptable robotics. Although significant work remains to integrate further sensory modules like humidity and pressure mapping, the team’s transformative approach overcomes long-standing barriers holding back multifunctional e-skins. | |

| Their creative crack localization technique also promises widespread benefits beyond novel sensors. Current and emergent flexible electronics fields ranging from displays to batteries to photovoltaics could all potentially capitalize on the methodology’s facility crisply inducing desired nanoscale conductive features onto durable substrates. And looking farther ahead, large-scale manufacturing scalability seems attainable by adapting advanced metallization production techniques like roll-to-roll printing. | |

| With increasing momentum around augmented and virtual reality interfaces plus radical shifts in the transportation landscape driven by electrification and automation trends strongly shaping the coming decades, the researchers believe the contributions of ultra-resilient and perceptive sensor skins will only continue growing in significance. This breakthrough work ushers in exciting new eras in wearable health tech, human-computer interaction, and responsive robotics – delivering durable multi-modal electronic skins unmatched in their environmental adaptability. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|