| Jan 18, 2024 | |

Nanoengineered flexible electronic skin senses strain, pressure and temperature |

|

| (Nanowerk Spotlight) Engineering electronic skin that truly mimics human skin has remained an elusive goal in materials science and bioengineering. To effectively integrate with the human body, e-skin must match the pliability, elasticity, sensitivity and self-healing capacity of our natural dermal tissues. Yet synthetic skins have consistently fallen short on critical mechanical and sensing fronts. Without the requisite softness, conformity and dynamic responses, their functionality severely limits adoption for advanced prosthetics, medical devices or wearable health trackers. | |

| Recent collaborative work between material scientists and chemical engineers at Texas A&M University demonstrates the tide may be turning on the e-skin challenge. Combining cutting-edge advances in hydrogels, nanotechnology and 3D printing, the researchers developed an innovative “triple-crosslinked” nanoengineered electronic skin. Their e-skin exceeded the flexibility of past prototypes and for the first time replicated the multifaceted sensing capabilities of its biological counterpart. | |

| As detailed in their recent paper in Advanced Functional Materials ("3D Printed Electronic Skin for Strain, Pressure and Temperature Sensing"), this breakthrough hyperelastic e-skin can simultaneously monitor dynamic changes in mechanical strain, pressure, and temperature - no easy feat. | |

|

|

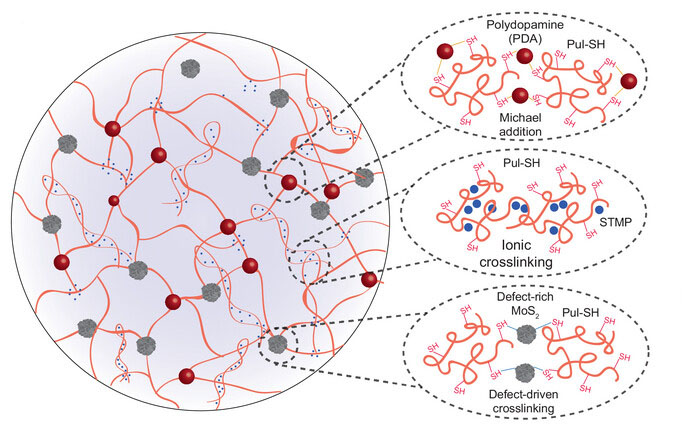

| Schematic showing the triple-crosslinking strategy involving defect-driven gelation, Michael addition, and ionic crosslinking to develop tissue adhesive, elastomeric, and conductive nanoengineered hydrogel. (© Wiley-VCH Verlag) | |

| Mimicking skin, the nanoengineered material stretches, bends and twists readily without compromising its integrity. Encased in thin, tissue-like hydrogel membranes, the e-skin’s embedded electronics also track subtle micro-motions, textures and temperatures comparable to human skin with high precision. | |

| This multimodal sensitivity could enable unprecedented advances in soft robotics, medical devices and next-generation wearables. The researchers’ holistic fabrication approach likewise overcomes major constraints that have historically obstructed viable e-skin technologies. Their synergistic blending of material components and nanoarchitecting techniques imparts unmatched mechanical compliance critical for interfacing with real human tissues. | |

| The researchers leveraged a novel thiolated derivative of pullulan, an FDA-approved polysaccharide, as the primary hydrogel backbone. They then reinforced this base gel matrix using both defect-rich MoS2 nanoassemblies and tissue-adhesive polydopamine (PDA) nanoparticles. The MoS2 nanoassemblies feature abundant sulfur vacancies that enabled covalent “defect-driven” gelation with the thiolated pullulan chains. Meanwhile, the PDA nanoparticles formed additional Michael addition crosslinks. Ionic crosslinks mediated by sodium trimetaphosphate (STMP) established a 3rd reinforcing network. Together, these three synergistic crosslinking mechanisms produced a robust, adhesive, conductive and elastic hydrogel composite optimized for 3D printing. | |

| This unique nanoengineered material displayed exceptional mechanical properties on par with human skin, stretching up to 90% strain without fracture. It could withstand repeated bending, twisting and compression - and even adhere to biological tissues - all without compromising its physical integrity. The shear-thinning characteristics facilitated smooth 3D printing of the e-skin into diverse shapes like sensors, actuators or drug delivery constructs. The printed structures also demonstrated stability and effective interlayer bonding during printing. | |

| Notably, the e-skin hydrogel also exhibited electrical conductivity stemming from the embedded MoS2 nanoassemblies. As confirmed by impedance testing, moderate MoS2 concentrations produced optimal conductivity, while higher levels precipitated a saturation effect. The conductivity enabled real-time strain and pressure sensing. | |

| Under repeated compression cycles simulating dynamic mechanical stress, the hydrogel displayed reversible, linear and reproducible changes in electrical resistance. Encased in thin protective layers, 3D printed e-skin sensors effectively tracked complex human motions like finger bending, twisting, pressing and tapping in distinctive resistance patterns. | |

| Even subtle stimuli like coughing, swallowing and blowing elicited measurable signals. The sensitivity, consistency and wide sensing range could enable applications like flexible keyboards, touchpads and wearable vocal monitors. | |

| Additionally, the nanoengineered e-skin proved its effectiveness as a flexible thermometer. Owing to its negative temperature coefficient and thermal isolation layers, the 3D printed hydrogel sensors produced linear responses across a broad temperature spectrum spanning hypothermic to febrile conditions. The e-skin reliably differentiated between hot and cold stimuli over repeated exposure cycles. It also demonstrated quick response times, needing only 6 seconds to register significant resistance changes when approaching heat sources like human skin. Used as a body temperature monitor, the conformal e-skin sensors successfully measured the 98-104°F fever range in a clinically relevant manner. | |

| The unprecedented integration of elasticity, bioadhesion, electrical conductivity and 3D printability sets this new nanoengineered e-skin platform apart from past efforts. The capacity to stably distinguish strain, pressure and temperatures comparable to human skin also has no precedent in the field. As the researchers summarize, their synergistic triple-crosslinking approach overcomes major limitations holding back e-skin development for decades. | |

| The study showcases the first 3D printed electronic skin with the potential flexibility, sensitivity and customizability to monitor an array of biomechanical and thermal signals critical for advancing healthcare and wearable technologies. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|