| Feb 01, 2024 | |

New low-temperature plasma technique unlocks flexible mesoporous metal oxides |

|

| (Nanowerk Spotlight) Mesoporous metal oxides (MMOs) – materials with tiny, interconnected pores – are coveted for integration in flexible electronics. Their high surface area lends utility across applications from energy storage devices to chemical sensors. However, reliably synthesizing MMOs has proven extraordinarily challenging. These intricate nanostructures typically require production temperatures exceeding 350 °C, incompatible with plastic substrates. And attempts to manufacture MMOs at lower temperatures have achieved limited success, often resulting in collapsed pore structures unusable for advanced devices. | |

| Specifically, the high-temperature method has two critical drawbacks: | |

|

|

| Now, scientists led by Prof. Jin Kon Kim at POSTECH in South Korea have demonstrated a versatile new technique that could finally make direct, low-temperature fabrication of MMOs on heat-sensitive plastics feasible. Their approach combines modest heating with oxygen plasma to drive pore formation and template removal at just 150-200 °C. | |

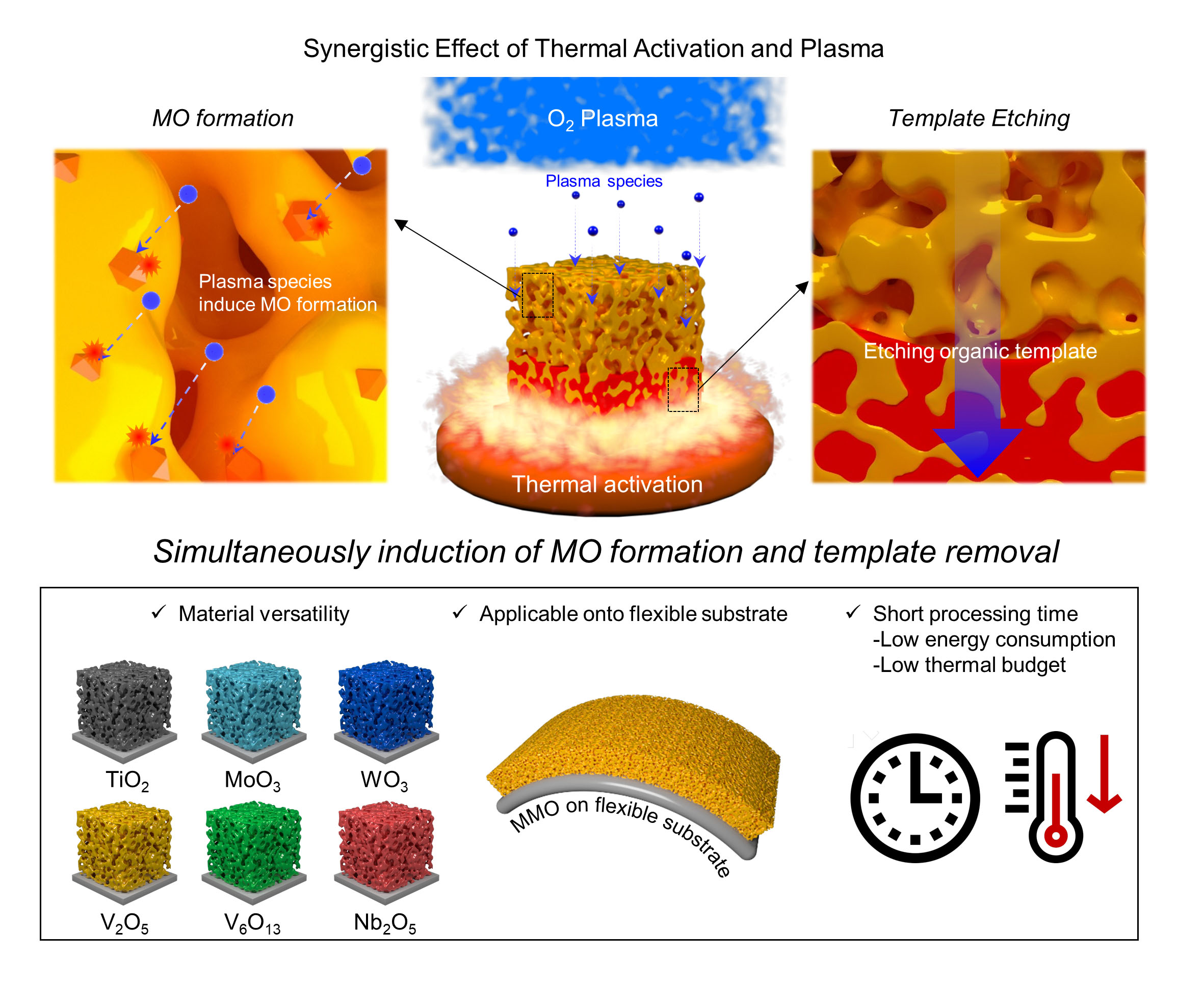

| The team developed an innovative approach that concurrently accomplishes template removal and metal oxide (MO) formation at low temperatures. This method harnesses the synergistic effects of thermal activation and oxygen plasma. Through systematic analysis, the researchers elucidated the roles of heat and plasma in facilitating template removal and MO formation. As a result, they achieved the successful fabrication of various MMOs and direct synthesis on a flexible substrate, a feat previously unattainable with traditional high-temperature synthesis methods. | |

| Publishing their findings in Advanced Materials ("Low-Temperature, Universal Synthetic Route for Mesoporous Metal Oxides by Exploiting Synergistic Effect of Thermal Activation and Plasma"), the researchers showcase remarkable control synthesizing a range of porous metal oxides. | |

|

|

| The overall schematic illustration of the thermal activation and plasma method. (Image: Courtesy of the researchers) | |

| "The new thermal activation and plasma (TAP) method opens doors for integrating MMOs onto flexible electronics," Kim explains to Nanowerk. Previously high production temperatures restricted these materials to rigid devices. The TAP technique opens new possibilities for integrating MMOs into flexible, wearable electronics. Previously these materials were restricted to rigid devices.” | |

| The versatility of the new approach stems from the use of self-assembling block copolymer (BCP) templates. By tuning BCP chemistry, the researchers can dictate the nanoscale structure of resulting MMO syntheses across material classes. The BCPs form mesoscale templates that guide precursor condensation. | |

| But removing BCPs after structure direction has been a persistent hurdle for low-temperature MMO fabrication. | |

| According to Kim, the TAP method navigates this longstanding tradeoff. Ion bombardment transfers kinetic energy for template etching while radicals drive oxide crystallization across entire films. | |

| We realized the synergistic effect of thermal activation and plasma could play complementary roles allowing MMO synthesis below 200 °C,” Kim says. “This opened the door to direct integration on flexible polymeric substrates.” | |

| To demonstrate capabilities, the researchers employed TAP to fabricate high-surface-area mesoporous vanadium pentoxide (MVO) – an archetypal MMO candidate for energy storage. This material was directly synthesized on flexible indium-tin oxide coated polyimide to construct an interdigitated micro supercapacitor. | |

| Notably, the TAP-produced MVO significantly outperformed its conventionally processed counterpart. With over 90% capacity retention after 10,000 cycles, the low-temperature flexible MSC exhibited energy storage capabilities on par with state-of-the-art rigid vanadium pentoxide supercapacitors. | |

| "The performances are very competitive, which proves our success synthesizing MMOs while almost eliminating tradeoffs,” Kim points out. “Extraordinary mechanical durability is inherent when you can directly synthesize MMOs on plastic substrates. | |

| Looking forward, Kim expects TAP will soon become a mainstream MMO fabrication strategy – especially for flexible devices. Ultralow synthesis temperatures open integration pathways across heat-sensitive substrates promising for wearables and flexible electronics. | |

| But the technique’s versatility likewise creates opportunities to enhance existing MMO applications through architectural control. From filtration membranes to photochromic glass, directly tailored mesostructures could drive efficiency and multifunctionality improvements. | |

| “Really, anywhere highly porous metal oxides are useful, I expect you’ll see TAP-enabled materials overtake current solutions,” Kim suggests. “The technique finally unlocks low-temperature, direct synthesis capabilities people have wanted for years.” | |

| Initial industry uptake supports Kim’s optimism. The researcher says his group has already received numerous partnership requests from companies working in batteries, capacitors, catalysts and sensors. | |

| Yet despite excitement, Kim acknowledges fundamental questions remain regarding scalability. The science may allow MMO integration flexibility, but practical applications will ultimately hinge on manufacturing readiness. | |

| In the meantime, Kim aims to expand the materials scope for low-temperature TAP while further optimizing pore morphologies. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|