| Feb 16, 2024 | |

Engineered living materials achieve reconfigurable growth |

|

| (Nanowerk Spotlight) Morphogenesis marks one of nature’s most astonishing feats. Starting from a single cell, cascading genetic and physical patterns progressively sculpt intricate structures exquisitely tailored for specialized function - spikes for snails, smooth skin for sharks, branched airways in human lungs. | |

| Morphogenesis refers to this innate biological process that guides developmental growth and structural configuration into precise target shapes. Yet while biological organisms inherently self-assemble such wondrous diversity of form and function, traditional manufacturing methods remain rigid and fixed. | |

| Yet while biological organisms innately self-assemble such amazing diversity, traditional manufacturing methods remain rigid. Proliferating populations of identical components to programmatically self-create optimized application-specific architectures has eluded artificial systems. Without such autonomous remodeling and adaptation in response to situational demands, current static platforms fail to fully capture the brilliance of living matter. | |

| Recent efforts have combined living cellular components with non-living engineered materials to create “living materials” with enhanced functionalities. For example, researchers have developed living materials using bacterial cellulose, mineralization processes and fungal mycelia networks. However, existing techniques lack fine-grained control over geometry changes during growth. | |

| Now, an interdisciplinary collaboration between Texas A&M’s departments of Materials Science & Engineering and Biomedical Engineering has actualized an exciting step toward emulative biofabrication. | |

| Published in Advanced Materials ("Reconfigurable Growth of Engineered Living Materials"), the group created a magnetically responsive cell-impregnated hydrogel that substantially replicates natural developmental processes at the mesoscale. Through deliberate magnetic confinement coupled to proliferative expansion, this “living material” system was grown into various non-uniform shapes in a reprogrammable manner. Such guided orientation of component self-assembly mirrors the meticulous control of morphogenesis in multicellular organisms. | |

|

|

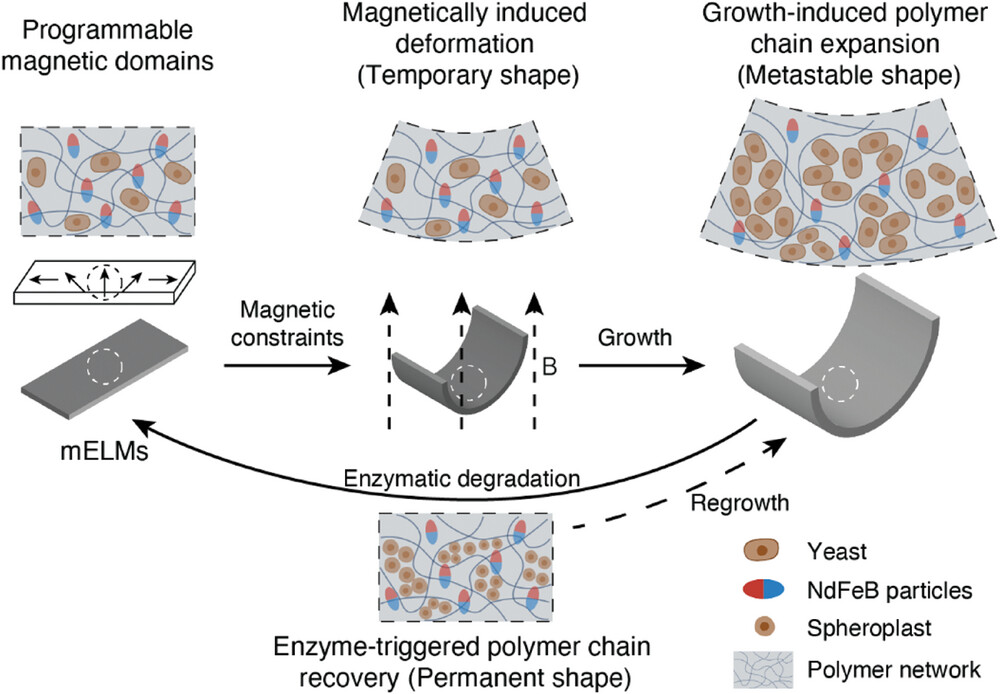

| Schematic illustration showing the reconfigurable growth of mELMs for shape manufacturing. Magnetically aligned magnetic engineered living materials (mELMs) deformed into the programmed temporary shape under a magnetic field. During growth, proliferated, stiff yeast cells stretch the polymer chains. The initial shape can be recovered through enzymatic degradation of the yeast cell walls. Yeast transformed into spheroplasts with the removal of stiff cell walls, leading to polymer chain relaxation and mELMs shape recovery. The recovered mELMs could be manufactured into a new shape again through repeated confined biological growth. (Reprinted with permission by Wiley-VCH Verlag) | |

| Through precise control of magnetic forces and in situ cell proliferation, the living materials can be additively manufactured into various programmed geometries. Enzymatic treatment allows the deformed materials to recover their original shapes, setting the foundation for reusable, reconfigurable and sustainable biomanufacturing. | |

| This new research demonstrates an exciting route to programmable, reconfigurable living materials by integrating lessons from natural morphogenesis. Through deliberate magnetic actuation coupled with biological proliferation, the materials can be additively grown into desired shapes. Recovering the original form then enables iterative reconfiguration into new geometries – emulating the repetitive tissue remodeling that occurs during development. | |

| The key innovation lies in the composition of the reported living materials. The researchers developed aqueous dispersions containing acrylic monomers, a photoinitiator, cellulose nanocrystals, live yeast cells and magnetic neodymium-iron-boron (NdFeB) microparticles. Under UV irradiation, the monomers rapidly crosslink to form non-biodegradable hydrogels in which the remaining components remain viably encapsulated. | |

| The magnetic particles allow external control over shape changes using magnetic fields, while encapsulated S. cerevisiae yeast drive large volume expansion during growth on nutrient media. After sufficient proliferation, the stiffer yeast cells mechanically stretch the compliant hydrogel network. Incorporating different magnetic particle concentrations revealed a trade-off between increased magnetic responsiveness and reduced cell growth. Balancing these factors led the team to focus on hydrogels with 3% magnetic particles by volume. | |

| With the optimally tuned living material in hand, the researchers demonstrated the concept of guided growth under confinement. They deformed rectangular hydrogel films into bent shapes using magnetic actuation from an external field. Crucially, samples maintained their imposed curved forms during cell proliferation in growth media. | |

| Despite releasing the magnetic field after growth, the deformed geometries remained fixed. In contrast, non-growing samples exposed to the same magnetic treatment almost fully recovered their original flat morphology. This indicated the cells’ proliferative expansion can permanently imprint magnetic deformations into the living materials. | |

| Through modeling and experiments, the team revealed that seeded cell growth stretches the surrounding polymer matrix over time. These elastic distortions become “locked in” by the persistent mechanical influence of new biomass. Programmed magnetic confinements therefore direct irreversible morphology changes. | |

| Capitalizing on this growth-based shape-locking phenomenon enabled a technique for additive manufacturing of non-uniform and reconfigurable geometries. The team showed that pre-programming magnetic orientation patterns, then growing samples under magnetic fields, sculpted the living materials into predictable curved configurations. | |

| Tuning magnetic field strengths during growth offered precise control over the final forms adopted. Most impressively, the researchers demonstrated complete reversibility of the shape changes through enzymatic removal of cell wall rigidity. This allowed original flattened forms to be recovered after proliferation-induced deformation. Multiple cycles of enzymatic shape recovery and regrowth successfully produced reconfigurable transformations between multiple free-standing forms. | |

| Overall, this innovative biofabrication process marries sustainable living systems with programmable external controls. The resulting reversible morphology shifts emulate the repetitive tissue remodeling crucial for natural growth. As the authors highlight, adopting principles of biological development could transform manufacturing across sectors including electronics, energy and biomedicine. The living material system here exemplifies an exciting step toward ecologically efficient additive biomanufacturing. | |

| Next steps for this bioinspired platform include improving growth/recovery speeds for actuation applications, exploring 3D printed constructs to expand geometric capabilities and investigating alternative cell types to widen functionality. Nevertheless, by growing shape-changing materials instead of merely processing them, this research sets the stage for more adaptive, autonomous and sustainable approaches to materials production. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|