| Mar 25, 2024 | |

Scientists 3D print luminescent quantum dot-polymer architectures with potential for advanced optoelectronics |

|

| (Nanowerk Spotlight) Quantum dots, nanoscale semiconductors with unique light-emitting properties, have garnered excitement for years due to their potential to revolutionize technologies from solar cells to biomedical imaging. In particular, quantum dots made of organic-inorganic hybrid perovskite materials exhibit exceptional properties like color tunability, narrow emission bands, and high quantum yields. However, harnessing perovskite quantum dots' capabilities has proven challenging, as they are sensitive to heat and oxygen. | |

| Previous attempts to utilize perovskite quantum dots have largely relied on 2D patterning techniques on flat surfaces, limiting device geometry and performance. Some researchers have explored 3D printing perovskite composites, but melting-based printing processes thermally degrade the quantum dots. Other approaches like inkjet printing and laser writing enable patterning of quantum dot inks into microstructures, but face issues with process complexity and design constraints. | |

| A versatile method to directly 3D print perovskite quantum dots into complex architectures could open new avenues for advanced optoelectronic devices. | |

| Now, a research team led by Im Doo Jung at Ulsan National Institute of Science and Technology in Korea has developed a straightforward and effective approach to 3D print perovskite quantum dot-polymer composites at room temperature using direct ink writing. As reported in Advanced Functional Materials ("3D Printing of Luminescent Perovskite Quantum Dot–Polymer Architectures"), their method employs inks composed of prefabricated perovskite quantum dots and hydroxypropyl cellulose polymer dissolved in dichloromethane solvent. | |

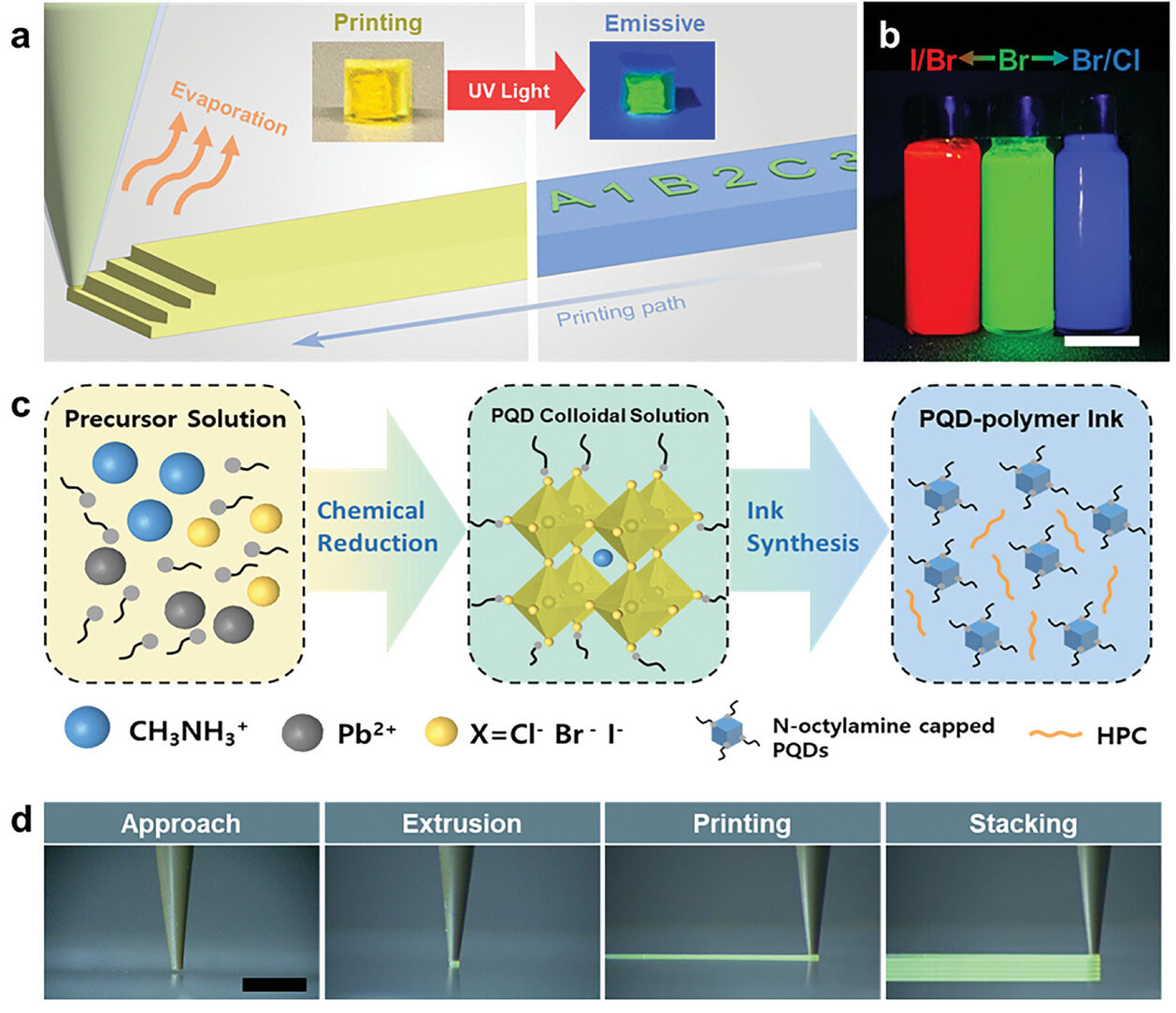

| The researchers synthesized the perovskite quantum dots via a ligand-assisted reprecipitation method. By mixing precursor solutions containing methylammonium halides, lead halides, and n-octylamine in specific ratios, they obtained colloidal dispersions of quantum dots with precise compositions. CH3NH3PbBr1.5I1.5 produced red emission at 639 nm, CH3NH3PbBr3 emitted green light at 515 nm, and CH3NH3PbBr1.5Cl1.5 exhibited blue emission at 467 nm. The choice of hydroxypropyl cellulose as the polymer matrix was key, as it is soluble in dichloromethane but optically transparent, enabling stable extrusion without obscuring the quantum dots' emission. | |

|

|

| a) Schematic of the direct-ink writing (DIW) approach of luminescent PQD–polymer architectures. Hydroxypropyl cellulose (HPC) polymer was dissolved in DCM to prepare a 3D printable ink. b) Optical image of the inks as visible in 385-nm ultraviolet (UV) light. PQD–polymer inks display red (R), green (G), and blue (B) emissive colors, corresponding to the halide ratios of CH3NH3PbBr1.5I1.5, CH3NH3PbBr3, and CH3NH3PbBr1.5Cl1.5. The scale bar is 5 mm. c) Schematic of the synthesis of luminescent PQDs as a colloidal dispersion solution in toluene, including the synthesis of PQD-polymer ink with HPC. d) Optical images of the DIW process show continuous deposition of a line pattern on the glass substrate. The scale bar is 1 mm. (Image: Adapted from doi: 10.1002/adfm.202400594, CC BY) | |

| Encapsulating the perovskite quantum dots in the cellulose polymer matrix not only enhanced their stability against heat and oxygen, but also allowed fine-tuning of the ink's rheological properties for smooth flow during printing and rapid solidification afterward to retain the printed shape. By carefully optimizing parameters like nozzle diameter, print speed, extrusion pressure, and ink composition, the team achieved high-fidelity 3D printing of complex quantum dot-polymer architectures at room temperature, overcoming the limitations of previous methods that degraded the fragile quantum dots. | |

| As a demonstration, Jung and colleagues printed 3D objects like pyramids and Eiffel towers by stacking hundreds of layers of red, blue, or green emitting quantum dot-polymer ink. Precise control over the print path and solidification enabled fabrication of such intricate, freestanding structures with feature sizes down to 150 µm. Fluorescence imaging and spectroscopic analysis confirmed the printed architectures retained the quantum dots' emission characteristics without degradation, showcasing the protective effect of the polymer matrix. | |

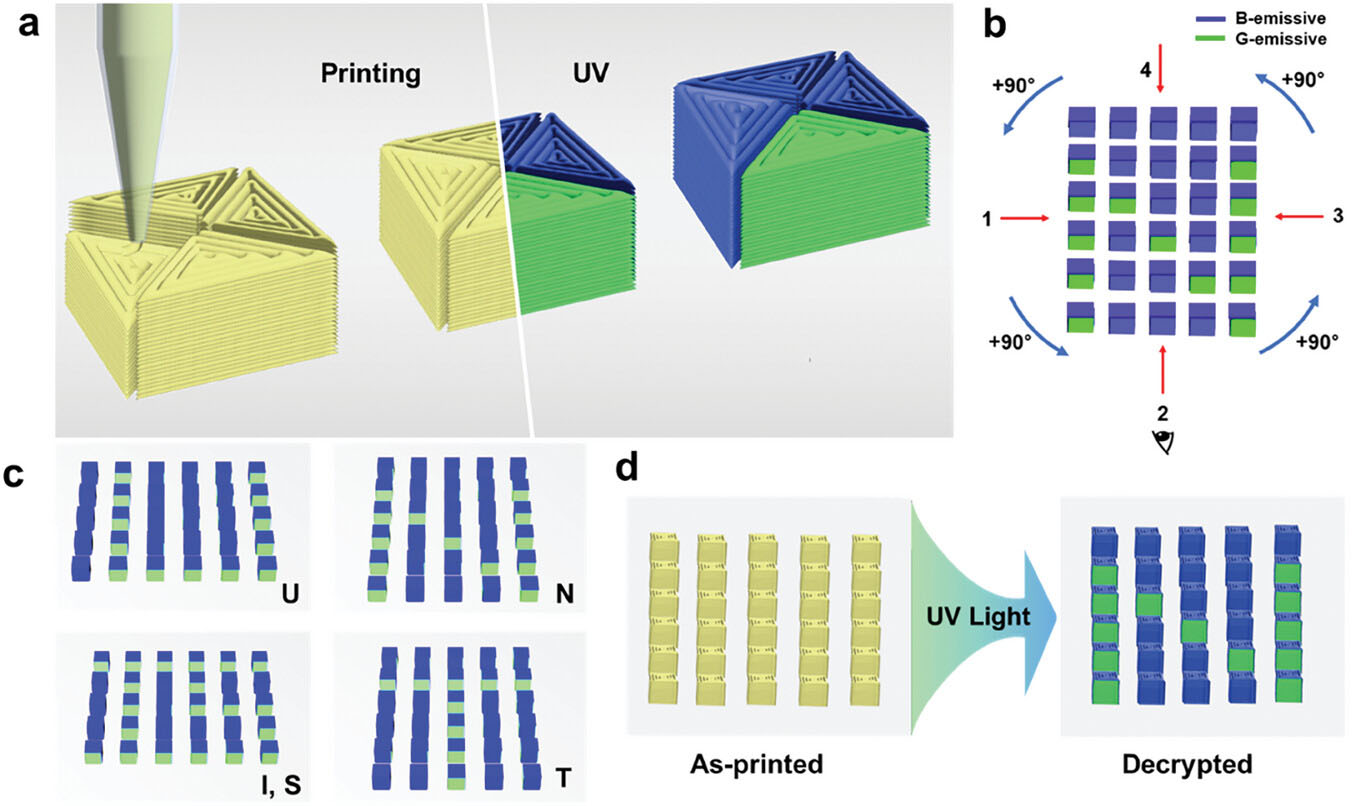

| The researchers also demonstrated the printed quantum dot composites' potential for anti-counterfeiting and information encryption, which are critical applications for securing documents, products, and data. By programming the print layout, they created 2D arrays of 3D cubes with patterns of blue and green squares only visible under UV light. Additionally, by arranging the blue and green cubes at different heights, the team encoded multi-layered hidden patterns, such as letters, that appear from specific viewing angles. These results highlight the unique opportunities enabled by 3D printing luminescent materials with spatially programmed functionality. | |

|

|

| a) Illustration of printed bicolor anti-counterfeiting cubic architectures comprising triangular units. b) Schematic design of a 6 × 5 3D array consisting of G- or B-emissive PQD–HPC on individual cube faces. The array sides encrypt information, with the denoting at 90° counterclockwise intervals. c) Design of a collective encryption of alphabets (U, N, I, S, T) as viewed from the top. The decryption in an inclined view of each array side, denoting U, N, IS, and T letters. d) Illustration of 3D printed 6 × 5 array cubic architectures under daylight and 385-nm UV light. The as-printed array decrypts information under UV light. (Image: Adapted from doi: 10.1002/adfm.202400594, CC BY) | |

| This novel 3D printing approach for perovskite quantum dot-polymer architectures holds immense promise not only for anti-counterfeiting, but also for next-generation optoelectronic devices. Compared to conventional 2D patterning, 3D architectures could increase active surface area, tune photonic properties, and allow integration of multiple devices in compact stacks. The room-temperature process maintains the outstanding properties of the quantum dots and is amenable to patterning on various substrates, offering great versatility. | |

| Building on this promising foundation, the researchers outline several avenues for further innovation. Careful encapsulation or crosslinking of the polymer matrix could improve stability. Optimizing ligand engineering and surface passivation of the quantum dots may enhance their optoelectronic performance. Incorporating conductive fillers or patterning electrodes would enable charge transport for light-emitting diodes and solar cells. | |

| As scientists continue pushing the boundaries of 3D printable functional materials and device architectures, a new era of advanced optoelectronics comes into view. With their exceptional properties and now unlocked potential for complex 3D patterning, perovskite quantum dot composites could revolutionize diverse technologies from displays and photovoltaics to anti-counterfeiting and information security. This research marks a major step forward in the quest to harness the full capabilities of these remarkable nanomaterials. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|