| Posted: Jul 24, 2008 | |

Nanotechnology fabrication based on inorganic replicas of complex biotemplates |

|

| (Nanowerk Spotlight) The use of design concepts adapted from nature is a promising new route to the development of advanced materials. There are quite a number of terms such as biomimetics, biognosis, biomimicry, or even 'bionical creativity engineering' that refer to more or less the same thing: the application of methods and systems found in nature to the study and design of engineering systems and modern technology. And increasingly, nanotechnology researchers find naturally occurring nanostructures a useful inspiration for overcoming their design and fabrication challenges. Because biological structures are the result of millennia of evolution, their designs possess many unique merits that would be difficult to achieve by a completely artificial simulation. | |

| We have written a number of Nanowerk Spotlights on this fascinating topic of nanotechnologists playing catch-up with nature: "Nature's bottom-up nanofabrication of armor ", "Nanotechnology inspired by mussels and seashells" or "Algae shells: one example how nanotechnology is trying to copy Mother Nature", to name just a few. | |

| By replicating the eye of a fruit fly, researchers have now demonstrated a highly reliable and low-cost technique for making inorganic replicas of biotemplates for fabricating complex nanostructures with biologically inspired functionality. | |

| "The exact imitation of biological structures by using equivalent processes to those used in nature is extremely difficult, since the mechanisms of formation of biological structures are tremendously complex,"" Dr. Akhlesh Lakhtakia explained to Nanowerk. "An alternative approach to fabricate replicas of biological shapes is based on 'converting' templates harvested from a particular species to inorganic materials. This approach could result in a highly reproducible and inexpensive process for the fabrication of complex nanostructures with unique functionalities. This way, structures can be made out of more stable, harder and high-temperature-tolerable inorganic materials." | |

| Lakhtakia, the Charles G. Binder Professor of Engineering Science and Mechanics at Pennsylvania State University, cautions however that two major problems can arise with this approach: First, there may be no technique available to grow high-fidelity replicas, particularly at the nanoscale; second, most physical or chemical techniques will result in damage or destruction of the original biotemplate. | |

| Reporting their work in the July 18, 2008 online edition of Nanotechnology, Lakhtakia together with Penn State colleagues Dr. Carlo Pantano and first author Dr. Raul Jose Martin-Palma, replicated the eye of a fruit fly at the micro- and nanoscales by implementing a novel technique, which allows the replication of even curved biotemplates ("Replication of fly eyes by the conformal-evaporated-film-by-rotation technique"). Pantano is Distinguished Professor of Materials Science and Engineering at Penn State. Martin-Palma is a Professor of Physics at the Autonomous University of Madrid. He was visiting Penn State while this work was being done. | |

|

|

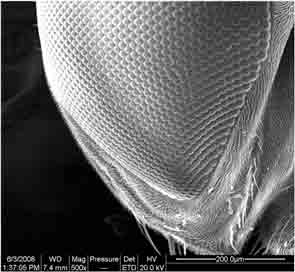

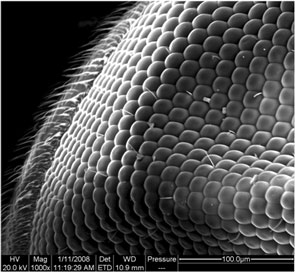

| Left: Structure of the eye of a tephritid fly (common fruit fly). Right: Scanning-electron microscope image of the coated biotemplate. (Reprinted with permission from IOP Publishing) | |

| "We were motivated by a very simple fact," said the authors: "Many structures have evolved in nature to display interesting and useful properties. The most appealing of these properties are optical, imparting either coloration and/or camouflage to the organism. Optical imaging structures such as compound eyes or polarization-sensitive eyes are also attractive. Some of these structures may have properties in the infrared regime, and therefore may not be easily appreciated by casual human observers. If we could replicate easily these and other attractive features – eg. superhydrophobicity of ciliated objects such as lotus leaves – we could exploit them for various technical or scientific purposes." | |

| Martin-Palma suggested: "For instance, the development of compound-eye-based miniature cameras and optical sensors could lead to their integration into tight spaces in automobile engineering, credit cards, displays, security and surveillance, and medical technology." | |

| Since the compound eyes of flies are very efficient collectors of light, their replicas could also be used to fabricate solar cell covers and other energy-harvesting structures as well as lenses offering good spatial resolution. | |

| Known methods for replication of biological structures include thin-film deposition methods such as thermal evaporation, electron-beam evaporation and sputtering, as well as other chemical methods. Atomic layer deposition (ALD) also has been used to replicate templates. ALD, however, produces replicas that lack spatial precision with increasing thickness. ALD, moreover, is limited to use with a limited number of materials and suffers from slow growth rate of film and extremely small film thickness (if you want to find out more about ALD, read our Spotlight "Atomic Layer Deposition - a true and tested nanotechnology"). | |

| The three authors point out, though, that nanoscale and non-planar features of these structures cannot be replicated by most of these known methods. Additionally, the use of biological templates is limited by the use of chemical and/or high temperatures. Furthermore, the fidelity of replication of these structures is enormously reduced as the thickness of the deposited film increases. | |

| "These known methods therefore are limited to deposition of films that are extremely thin, i.e., on the order of a few nanometers and/or to use with a limited selection of materials, thus limiting any practical application" stated the authors. "Furthermore, features oriented close to the normal of the growth direction of the film cannot be precisely replicated by these methods. These known methods therefore are not suited for use with biological templates that have curved surfaces." | |

| Lakhtakia, Martin-Palma and Pantano therefore saw a need for a method of replicating intricate features of templates ? such as biotemplates ? that address the deficiencies of the known methods. A need also existed for a method of manufacture of replicas having three-dimensionally embedded surfaces, such as the top surface of a microelectronics circuit. | |

| Their recent work addresses these needs. | |

| In a technique that they call 'conformal-evaporated-film-by-rotation' (CEFR), the three researchers successfully replicated a biotemplate – the compound eye of a common fruit fly – by rapidly rotating it and implementing the 'oblique angle deposition' (OAD) technique. OAD basically combines a typical deposition system with a tilted substrate. | |

| "Our method is particularly suited for use with curved templates including micro- and nanostructured templates," said Martin-Palma. "Our method creates an actual replica of the template rather than an inverted structure of it. Our method, moreover, achieves high growth rates, typically about 0.5 micron per minute." | |

| The researchers mention that CEFR also may be used to produce replicas from insulating materials, metals, semiconductors, semimetals, polymers and organic materials. "For example, infrared transparent materials such as chalcogenide glasses to produce infrared micro lenses and visible laser-hardened infrared sensors, as well as photodiodes, solar sensors, solar concentrators, photonic crystals, optical bioprobes and the like," Pantano said. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.