| Posted: Oct 03, 2006 | |

Highly efficient antibacterial nanocomposite coatings with gold and silver nanoparticles |

|

| (Nanowerk Spotlight) The potential use of antimicrobial surface coatings ranges from medicine, where medical device infection is associated with significant healthcare costs, to the construction industry and the food packaging industry. Thin films which contain silver have been seen as promising candidate coatings. Silver is known as one of the oldest antimicrobial agents. Silver ions are thought to inhibit bacterial enzymes and bind to DNA. Silver has been used effectively against different bacteria, fungi and viruses. Researchers in Germany developed a new method for producing antibacterial metal/polymer nanocomposite coatings, where silver and gold nanoparticles are only incorporated in a thin surface layer. The new material shows a greatly enhanced antibacterial efficiency of the thin films. | |

| Dr. Vladimir Zaporojtchenko, from the Chair for Multicomponent Materials at the University of Kiel in Germany,explained the new findings to Nanowerk: "We developed a new co-deposition process based on sputtering to protect a surface against growth of bacteria by depositing a thin nanocomposite film consisting of silver particles in a fluoropolymer matrix. The well-known antibacterial activity of silver is greatly enhanced by depositing an additional very thin layer of gold clusters. The much more effective release of silver ions form the coating is attributed to the combination of clusters of silver with clusters of the nobler gold." | |

| Zaporojtchenko is first author of a recent paper, titled "Physico-chemical and antimicrobial properties of co-sputtered Ag–Au/PTFE nanocomposite coatings", that was published in the September 11, 2006 online edition of Nanotechnology. | |

|

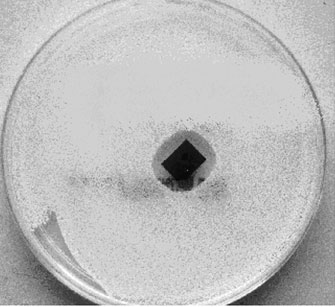

Agar diffusion test showing a zone of growth inhibition of S. aureus ATCC 6538 by a substrate with Ag/PTFE nanocomposite coating. (Reprinted with permission from Institute of Physics Publishing) |

| Different silver-based approaches for preventing microbial adhesion have been proposed previously. However, the resulting materials have shown controversial or sometimes disappointing clinical results. Conventional ionic silver preparations such as silver nitrate are quickly inactivated in biological fluids because different biologically inactive complexes are formed. Other techniques like impregnation of silver in the bulk material lead to ineffective use of the expensive impregnated silver particles and decrease of the antibacterial efficiency because of the longer diffusion lengths of the bulk materials. As a result, large quantities of silver cannot be used to provide antimicrobial activity. | |

| "It is therefore necessary to optimize the antimicrobial coating according to defined silver ion release and to required time" says Zaporojtchenko. "Therefore, it seems more effective to use nanocomposite coatings with embedded silver nanoparticles, which provide a very large effective surface for metal ion release." | |

| In the nanocomposite coating fabricated by Zaporojtchenko and his co-workers silver is finely dispersed as nanoparticles, thus saving additional material and providing a very large effective surface for metal ion release. | |

| Professor Franz Faupel, who heads the Chair for Multicomponent Materials, points out that his group has demonstrated that silver/polymer nanocomposite films consisting of small silver nanoparticles embedded in polymer matrix can be effectively prepared by using co-sputtered processes. "This technique allows us to prepare thin composite coatings with large ranges of metal filling with different coating thickness" he says. | |

| The research of the German scientists provides new aspects for producing antibacterial nanocomposite coatings. One is the strong enhancement of the antibacterial activity of silver clusters by combining them with a small amount of gold clusters that are not consumed. Another is the new deposition process, involving sputtering of Teflon and co-sputtering of silver, that has not been applied to antibacterial coatings before. | |

| The field of polymer-based functional nanocomposites is very promising. In addition to antibacterial coatings, Faupel's group works on optical coatings, where one takes advantage of plasmon resonances in noble metal nanoclusters, and on magnetic high frequency materials for applications in the GHz range, which is interesting for telecommunications and sensors. Here the main idea is to suppress eddy currents by dispersing the magnetic component in an insulating polymer matrix. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.