What Are Nanocomposites?

A nanocomposite combines two or more materials – of which at least one is a nanomaterial – with different physical and chemical properties. Nanocomposite materials are designed to exhibit properties that exceed, sometimes drastically, the capabilities of the sum of their constituent parts.

In the future, the wings of jets could be as light as balsa wood, yet stronger than the toughest metal alloys. That's one of the promises of nanocomposite materials.

How Are Nanocomposites Made?

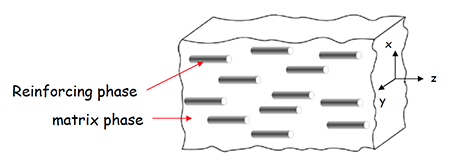

Nanocomposites are made by embedding materials (called the reinforcing phase) into another material (called the matrix phase). Either one or both phases can be nanomaterials.

Typically, reinforcing materials are strong with low densities while the matrix commonly is a ductile or tough material. If the composite is designed and fabricated correctly, it combines the strength of the reinforcement with the toughness of the matrix to achieve a combination of desirable properties not available in any single conventional material.

Illustration of the matrix phase and reinforcing phase of nanocomposites. (Image: Nebraska Center for Materials & Nanoscience)

Nanocomposites are often prepared by chemically oriented synthetic methods: Soft lithography, soft lithography, lamination, spin-coating or solution casting.

The primary challenge in the processing of nanocomposites is achieving a homogeneous dispersion of the nanoparticles. The dispersion quality affects the interfaces between the phases, which can determine the final properties of the nanocomposite.

By including different materials, structures, and compositions in the nanocomposites, it becomes possible to tune different properties (such as mechanical, electrical, thermal, magnetic or even acoustical), making the nanocomposite material suitable for various applications. That's why nanocomposites also gave rise to the fast growing field of multifunctional materials.

Fillers with nanoparticles have a small number of atoms per particle and for this reason may have different properties than the bulk material and strong interactions with the matrix. It is believed that the molecular level interactions between the nanoparticles and matrices along with the presence of very high nanoparticle-matrix interfacial area play a major role in influencing the physical and mechanical properties of nanocomposites.

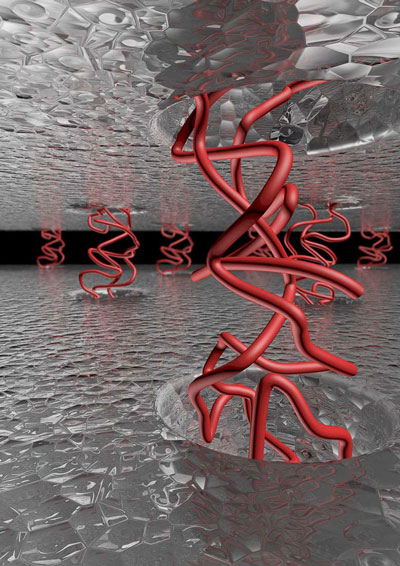

Stanford and IBM researchers inserted chain-like molecules of polystyrene – the same material in a Styrofoam coffee cup – between layers of nanocomposites to make these materials tougher and more flexible. (Image: Stanford University)

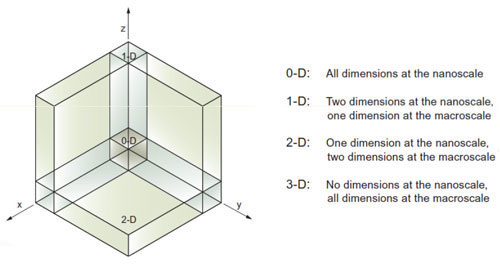

The nano-constituent in nanocomposites may be confined in nanoscale domains in one, two, or three dimensions for the unusual size-dependent behavior:

Read our article on nanoparticles to understand why these dimensions matter and why materials behave differently at the nanoscale.

Classification of nanoscale dimensions. (Source: Tallinn University of Technology)

Nanocomposites can be fabricated not only with different nanostructured materials but also with various biomolecules and conducting polymers. For instance, researchers combined two different materials from nature, both of which have unique and important properties, into one material system via genetic engineering. By combining the features of silk with biosilica through the design, synthesis, and characterization of a novel family of chimeric proteins they fabricated an innovative biomimetic nanocomposite.

Polymer Nanocomposites

Polymeric nanocomposites – materials incorporating nanosized inclusions into the polymer matrices – represent a major area in the field of nanocomposites. They exhibit excellent mechanical properties, enhanced modulus and dimensional stability, flame retardancy, improved scratch and mar resistance, superior thermal and processing properties, reduced warpage of components and enhanced impact resistance making them suitable to replace metals in various industrial applications.

Classification of polymer- and non-polymer-based nanocomposites. (© IntechOpen)

The exponential growth of polymeric nanocomposites began with the discovery of fullerenes (also known as C60 or buckyballs). This discovery paved the road for discovery of carbon nanotubes (CNTs) and later graphene, all of which have become important filler materials for nanocomposites.

Some of the most major improvements achieved from the introduction of nanofillers into polymeric matrices are enhancement of mechanical properties, improvements in thermal and electrical properties from the incorporation of CNTs, flame retardant properties in the case of the introduction of nanoclays and metal hydroxides, thermal stability, gas permeability, and so on.

The combination of CNTs has also raised significant interest in the development of shape memory materials due to the electrical properties of these nanocomposites. Shape memory materials have the capability of being deformed into a temporary shape with the help of an external stimulus. The electrical properties of CNTs allow using electrical current to control smart actuators for many different applications.

Moreover, the organic origins of some nanofillers, such as nanocellulose, allow the usage of these materials for medical purposes due to their biocompatibility.

Overall, polymer nanocomposites have spawned huge interest for the development of high-performance products such as lightweight sensors, thin-film capacitors, batteries, flame retardant products, biodegradable and biocompatible materials.

Nanocomposite Types And Applications

The application areas for nanocomposites includes medical areas and spans many industries, from electronics to automotive to sport equipment. They could even revolutionize aeronautics and spaceflight with their ability to withstand tension and extreme temperatures.

Epoxy-based nanocomposites

Epoxy, a thermosetting polymer, is a widely used industrial material with a multitude of applications. Epoxy-based nanocomposites are quite adaptable materials used in various engineering applications for their high strength and light weight. For instance, high-loading graphene epoxy composites are promising thermal interface materials that can be used for improving heat conduction from computer chips, light-emitting diodes, and microwave sources.

Polymer Nanocomposites in the Automotive Industry

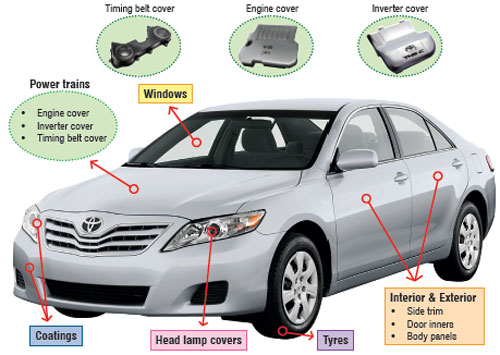

The key drivers for the use of polymer nanocomposite-enabled parts in the automotive industry are reduction in vehicle's weight, improved engine efficiency (fuel saving), reduction in CO2 emissions and superior performance (greater safety, increased comfort and better driveability).

An illustration of the usage of polymer nanocomposites parts in the automotive industry.

Read more in our detailed Nanowerk Spotlight about how polymer nanocomposites drive opportunities in the automotive sector.

Carbon Nanotube Enabled Nanocomposites

Carbon nanotube enabled nanocomposites have received much attention as a highly attractive alternative to conventional composite materials due to their mechanical, electrical, thermal, barrier and chemical properties such as electrical conductivity, increased tensile strength, improved heat deflection temperature, or flame retardancy.

Graphene Enabled Nanocomposites

Graphene uniquely combines great mechanical and tensile strength, a large surface area, high chemical stability, with superior thermal and electrical conductivity. Properties which give the material extraordinary potential.

One area where graphene and graphene-based composites currently hold out much promise is as replacement materials for electrodes in energy storage devices. To date, graphene has significantly increased the capacity and efficiency of Li-ion batteries and supercapacitors.

For example, researchers have created a graphene and tin nanoscale composite material for high-capacity energy storage in renewable lithium ion batteries. By encapsulating tin between sheets of graphene, the researchers constructed a new, lightweight sandwich structure that should bolster battery performance.

Quantum Dot Enabled Nanocomposites

Researchers have performed live cell imaging with biodegradable quantum dot nanocomposites. By fabricating a hybrid nanocomposite of bio-degradable hydrogel and quantum dots, they created a delivery system that carries the nanoparticles into the cytoplasm. This allows the labeling of subcellular organelles or other molecular targets for biomedical studies.

Nanocomposites in Food Packaging

Nanoclays, which are added to, for example, polypropylene or polylactic acid packaging films, prevent the diffusion of oxygen or flavorings and thus prolong the shelf life of foods. Nanosilver has an antimicrobial effect and can be used in plastics composites, for example to manufacture food packaging such as films or containers to protect food from spoilage.

Nanocomposites represent a new alternative to conventional technologies for improving polymer properties. Nanocomposites exhibit increased barrier properties, increased mechanical strength, and improved heat resistance compared to their neat polymers and conventional composites. Particle fillers used and proposed in the literature include the nanoclays montmorillonite (MMT) and kaolinite, carbon nanotubes, and graphene nanosheets.

Other Application Areas For Nanocomposites

This list of nanocomposite-based devices and uses should give you an idea of the breadth of applications and is by no means complete: