| Sep 25, 2019 | |

Inspired by nacre, epoxy-graphene layered nanocomposites are tough and self-monitoring |

|

| (Nanowerk Spotlight) Epoxy, a thermosetting polymer, is a widely used industrial material with a multitude of applications. Epoxy-based nanocomposites are quite adaptable materials used in various engineering applications for their high strength and light weight. For instance, as we reported previously, high-loading graphene epoxy composites are promising thermal interface materials that can be used for improving heat conduction from computer chips, light-emitting diodes, and microwave sources. | |

| To make epoxy-graphene nanocomposites, the graphene nanosheets are commonly mixed homogeneously with the epoxy matrix. However, one of the problems that bedevils these nanocomposites is the issue of agglomeration of the nanofillers: their poor dispersion in the epoxy matrix significantly limits the effectiveness of the nanofillers on the overall composite's performance such as fracture toughness or thermal conductivity. Performance is also hampered by the weak interface interactions between graphene and the epoxy matrix. | |

| To solve the aggregation issue, conventional solutions include sonification, high-pressure extrusion, surfactant modification, and many others. Nevertheless, nanofiller aggregation is still hard to overcome, especially with higher contents of nanomaterials, which severely hinders the improvement of the composites' mechanical properties. | |

| Researchers now report that they have sucessfully tackled this dispersion problem by constructing a continuous graphene-based scaffold. The results, published in Matter ("Inverse Nacre-like Epoxy-Graphene Layered Nanocomposites with Integration of High Toughness and Self-Monitoring"), show that the team's novel strategy boosts the fracture toughness to about 3.6 times that of pure epoxy. | |

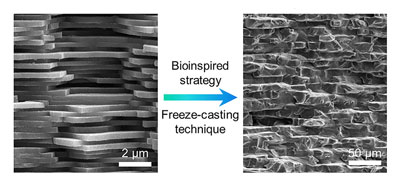

| The scientists' approach for this composite toughening mechanism was inspired by natural nacre, the pearly internal layer of many mollusc shells. It has evolved through millions of years to a level of optimization currently achieved in very few engineered composites. Nacre has a layered structure composed of approximately 96 wt% calcium carbonate (CaCO3) nanoscale building blocks interfaced by about 4 wt% organic materials (soft biopolymers). The typical characteristic of nacre is the 'brick and mortar' arrangement, which is thought to be crucial to mechanical and other outstanding properties that nacre possesses. | |

|

|

| Left: Natural nacre. Right: Inverse nacre-like epoxy-graphene layered nanocomposites. (Reprinted with permission by Cell Press) | |

| "Our hypothesis was that nacre could provide a new design concept for constructing epoxy nanocomposites with high fracture toughness," Qunfeng Cheng, a professor at Beihang University in Beijing, who led this work, tells Nanowerk. "In our work, we put forward the concept of inverse nacre-like layered epoxy-graphene nanocomposites composed of ∼99 wt% organic epoxy matrix. | |

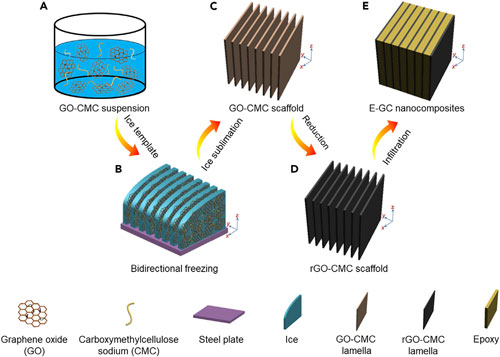

| As opposed to the conventional homogeneous mixing, the team's design strategy avoids the dispersion process of graphene nanosheets altogether. Rather, they use graphene nanosheets to construct a layered scaffold and then embed this scaffold into the epoxy matrix. | |

| The researchers fabricated this graphene-based layered scaffold via the ice-templating technique and then infiltrated the epoxy resin into the scaffold, thereby obtaining a layered graphene nanocomposite. | |

| "We were surprised that with only ∼0.3 wt% graphene-based scaffold, the fracture toughness is boosted to ∼2.53 MPa m1/2, which is ∼3.6 times that of pure epoxy," Cheng points out. "Constructing an interconnected conductive network within the insulating epoxy matrix is also effective in achieving excellent electrical conductivities compared with homogeneous blending. This conductivity, for instance, could be used for self-monitoring the structural safety and health of these nanocomposites." | |

|

|

| Schematic Illustration of the preparation of bio-inspired epoxy-graphene nanocomposites. (A?D) The graphene oxide (GO) suspension and carboxymethyl cellulose sodium (CMC) solution were uniformly mixed (A). A lamellar GO-CMC scaffold (C) was obtained by bidirectional freeze-casting (B) followed by freeze-drying, then annealed, forming a reduced graphene oxide (rGO)-CMC scaffold (D). (E) The rGO-CMC scaffold was infiltrated with epoxy to fabricate an inverse nacre-like E-GC nanocomposite. (Reprinted with permission by Cell Press) (click on image to enlarge) | |

| But he cautions that there are two key problems to be solved by the team's further work. Firstly, the inverse nacre-like layered epoxy-graphene nanocomposites demonstrated in this work are still limited to very small sizes. In order to be useful for practical applications, the large-scale fabrication of graphene-based scaffold via ice-templating needs to be developed in order to obtain large-size inverse nacre-like epoxy-graphene nanocomposites. | |

| Secondly, the inverse nacre-like structure needs to be further optimized, especially with regard to controlling the thickness of each epoxy layer so that they more closely resemble the CaCO3 nanoplatelets in natural nacre. With decreased thickness of the epoxy layers, it is expected that the density of the interface increases to facilitate the extrinsic toughening mechanism and further boost the fracture toughness. | |

| "Given the extraordinary electrical or thermal conductivity of graphene, a further design challenge for us is to integrate these functions with the mechanical properties of these nanocomposites in order to obtain multifunctionality," Cheng concludes. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|