| Posted: Jul 28, 2016 |

New cluster technology for surface polishing of materials

(Nanowerk News) Currently the main method of getting smooth surfaces is chemical-mechanical, or “wet” polishing. However, it has two disadvantages: residual pattern about 1 nm and defective near-surface layer. Moreover, in case of semiconductor production for “wet” planarization (removing of imperfections from the surface of manufactured semiconductor plate) it is necessary to break vacuum conditions.

|

|

The usage of beams of accelerated cluster ions as addition or replacement of the technology of chemical-mechanical planarization is currently one of the breakthrough directions in the development of technology of micro- and nanoelectronics. The usage of cluster ions enlarges the sphere of objects for planarization, for example, the method would have an advantage in the processing of superhard coatings like polycrystalline CVD diamond, silicone carbide, sapphire or quartz glass, because, unlike machine processing, spillage properties do not depend on the target mechanical parametres, and the abrasion level reaches about 0,1 nm.

|

|

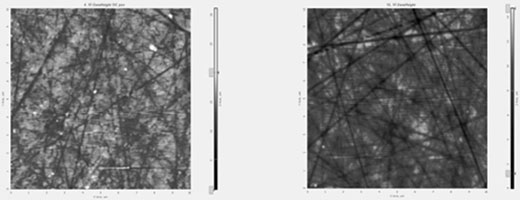

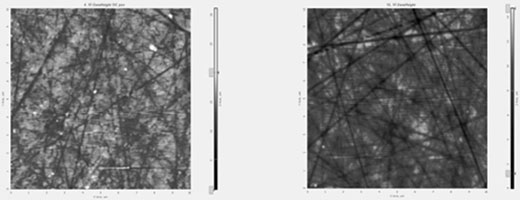

| AFM of the surface of 6H-SiC: a) surface before planarization; b) after 15 minutes of radiation by ion-cluster beam.

|

|

With an aim of creation of the new generation devices, corresponding to the highest standards of the semiconductor plates’ surface purity, employees of MEPhI Department of Condensed matter physics (No. 67) have come close to the creation of a new technology of planarization of silicone carbide materials’ surface by accelerator cluster ions. During their work scientists have researched the impact of ion-cluster radiation on the topology of plates’ surface of 6?-SiC crystals, raised by the Lely method. This processing was conducted with the help of nAccel 100 (Exogenesis) facility. Argon clusters, received in adiabatic gas expansion through supersonic nozzle, were ionized and accelerated by the pressure of 30 KeV. The pressure in the working camera was 3×10-4 torr.

|

|

The surface relief pattern of 6?-SiC plates before and after the impact of the beam of cluster ions was researched with the help of scanning probe microscope Solver Next. The size of analysed area was 10×10 mkm. The quantity analysis of the topology of each sample was conducted for 3 different areas of its surface. Then the meanings of the surface roughness were averaged.

|

|

The results of the scientists’ research show significant smoothing of the relief of 6H-SiC plates’ surface after their processing by a beam of cluster ions. Rq parameter is lowered 1,5 - 2 times. Thus, it has been proved in practice that gas cluster ions are an effective instrument of final smoothing of silicone carbide surface. However, it has not been possible to get rid absolutely of “diamond noise” (linearly structured faults), which means the necessity of enlargement of the radiation dose or energy of cluster ions, interacting with SiC surface.

|

|

The developed technology of planarization of materials’ surface is a breakthrough scientific experiment, conducted at the Department of Condensed matter physics. The scientists are sure that it will find its application in such areas as optoelectronics (for planarization both of substrates of optoelectronic devices and the surface of layers put on by planar technology for getting high-efficiency new generation optoelectronic devices), optics (for ultrathin polarizing of lenses) and microelectronics (for planarization of the surface both of semiconductor plates and substrates of lithographic masks for flawless ultrahigh-resolution lithography).

|