| Posted: Dec 07, 2016 |

Enhanced stability of perovskite solar cells through the development of new additives

(Nanowerk News) A NIMS research group led by Liyuan Han, Managing Researcher, Center for Green Research on Energy and Environmental Materials, developed new additives for the hole-transporting layer of perovskite solar cells, which greatly improved cell stability (Advanced Materials, "Enhanced Stability of Perovskite Solar Cells through Corrosion-Free Pyridine Derivatives in Hole-Transporting Materials").

|

|

When placed in the dark, the cells did not show signs of deterioration even after 1,000 hours of testing, and under continuous light soaking, they lasted six times longer—in terms of the time it takes for their power conversion efficiencies to fall to 85% of their initial states—compared to cells treated with conventional additives.

|

|

Thus, the new additives greatly enhanced cell stability. The researchers hope that these results will accelerate efforts toward practical application of perovskite solar cells.

|

|

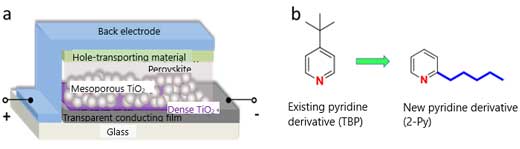

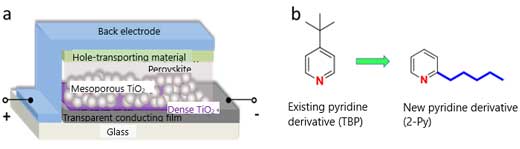

| a) Schematic of a perovskite solar cell in a normal structure. b) Molecular structures of an existing pyridine derivative (left) and a new pyridine derivative with an alkyl group (blue) attached (right).

|

|

Perovskite solar cells, which can be manufactured by solution processes, have attracted much attention since their power conversion efficiency have exceeded 20%. Though their conversion efficiencies are steadily increasing, their stability remains as a major issue.

|

|

For example, perovskite solar cells in a normal structure, consisting of titanium oxide, perovskite and a hole-transporting layer, demonstrate the highest conversion efficiency, but they have very poor stability, and their conversion efficiencies decline about 30% after 200 hours of testing even under dark.

|

|

Therefore, key issues for practical applications of these solar cells are to understand the causes of poor stability and development of new materials to improve the stability.

|

|

Recently, the research group directed their focus on a pyridine-based additive, TBP, which is used as an additive in a hole-transporting layer in the mesoporous-type cell structure. After conducting experiments and analyzing the results, the group found that chemical reactions occurring between TBP and perovskite materials were one of the major cause of stability deterioration.

|

|

Moreover, analyses using infrared spectroscopy and X-ray diffraction revealed that the chemical reaction mainly occurs between the nitrogen atom in the pyridine ring and perovskite crystals. The group successfully suppressed this undesirable reaction by adding an alkyl group to the position close to the nitrogen atom, leading to a steric hindrance effect (prevention of two reacting atoms from nearing each other in space).

|

|

Consequently, perovskite solar cells that contained the new pyridine derivatives maintained their performance over 1,000 hours in the dark. In addition, under continuous light exposure, application of conventional additives made cells last for slightly less than 25 hours, which is the time it took for the cells’ conversion efficiencies to decrease to 85% of their initial states.

|

|

In contrast, application of the new additives made the cells last for 150 hours. That is, the cells’ stability was increased by six times.

|

|

The research group first identified mechanisms of perovskite solar cell deterioration, then developed a new material based on the findings. This study demonstrated that the group’s approach is very effective in terms of improving the stability of solar cells. We will further investigate factors influencing solar cell stability, and continue to develop new materials with the aim of achieving practical use of perovskite solar cells as early as possible.

|

|

A part of these results was produced by implementing the project “Development of technology to reduce the cost of high-performance and high-reliability solar power generation,” sponsored by the New Energy and Industrial Technology Development Organization (NEDO).

|