| Aug 29, 2011 |

Tiny wires change behavior at nanoscale

|

|

(Nanowerk News) Thin gold wires often used in high-end electronic applications are wonderfully flexible as well as conductive. But those qualities don't necessarily apply to the same wires at the nanoscale.

|

|

A new study from Rice University finds gold wires less than 20 nanometers wide can become "brittle-like" under stress. It appears in the journal Advanced Functional Materials ("Fracture of Sub-20nm Ultrathin Gold Nanowires").

|

|

The paper by Rice materials scientist Jun Lou and his lab shows in microscopic detail what happens to nanowires under the kinds of strain they would reasonably undergo in, for instance, flexible electronics.

|

|

Their technique provides a way for industry to see just how nanowires made of gold, silver, tellurium, palladium and platinum are likely to hold up in next-generation nanoelectronic devices.

|

|

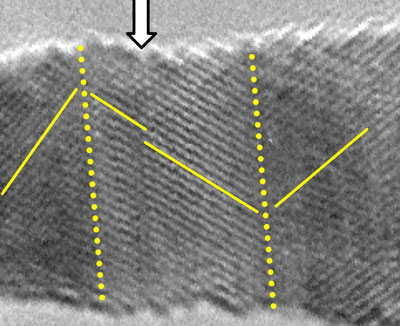

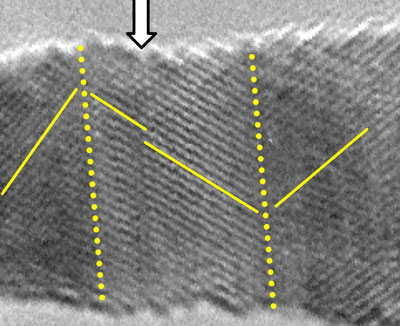

| A single crystal nanowire shows evidence of twinning under tensile loading in this electron microscope image. A new study by the Rice University lab of Jun Lou determined that tiny gold wires change their behavior at the nanoscale. (Image: Lou Lab/Rice University)

|

|

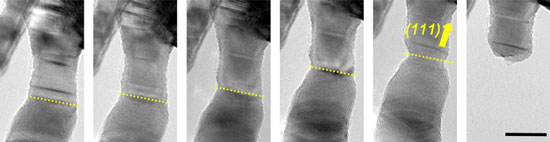

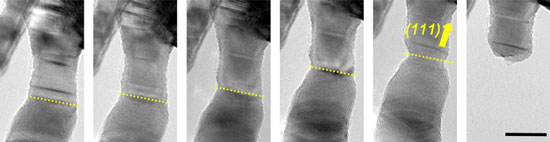

Lou and his team had already established that metal wires have unique properties on the nanoscale. They knew such wires undergo extensive plastic deformation and then fracture on both the micro- and nanoscale. In that process, materials under stress exhibit "necking"; that is, they deform in a specific region and then stretch down to a point before they eventually break.

|

|

"Gold is extremely ductile," said Lou, an assistant professor of mechanical engineering and materials science. "That means you can stretch it, and it can withstand very large displacement.

|

|

"But in this work, we discovered that gold is not necessarily very ductile at the nanoscale. When we stress it in a slightly different way, we can form a defect called a twin."

|

|

The term "twinning" comes from the mirrorlike atomic structure of the defect, which is unique to crystals. "At the boundary, the atoms on the left and right sides exactly mirror each other," Lou said. Twins in nanowires show up as dark lines across the wire under an electron microscope.

|

|

"The material is not exactly brittle, like glass or ceramic, which fracture with no, or very little, ductility," he said. "In this case, we call it brittle-like, which means it has significantly reduced ductility. There's still some, but the fracture behavior is different from regular necking."

|

|

Their experiments on 22 gold wires of less than 20 nanometers involved the delicate operation of clamping them to a transmission electron microscope/atomic force microscope sample holder and then pulling them at constant loading speeds. Twins appeared under the shear component of the stress, which forced atoms to shift at the location of surface defects and led to a kind of nanoscale tectonic fault across the wire.

|

|

| This series of electron microscope images shows a gold nanowire with several twin boundaries, which show up as dark lines. The wire fractures at the site of a groove that appears at the bottom twin. (Image: Lou Lab/Rice University)

|

|

"Once you have those kinds of damage-initiation sites formed in the nanowire, you will have a lot less ductility. The metal will fracture prematurely," Lou said. "We didn't expect such twin-boundary formations would have such profound effects."

|

|

With current technology, it's nearly impossible to align the grip points on either side of the wire, so shear force on the nanowires was inevitable. "But this kind of loading mode will inevitably be encountered in the real world," he said. "We cannot imagine all the nanowires in an application will be stressed in a perfectly uniaxial way."

|

|

Lou said the results are important to manufacturers thinking of using gold as a nanomechanical element. "Realistically, you could have some off-axis angle of stress, and if these twins form, you would have less ductility than you would expect. Then the design criteria would have to change.

|

|

"That's basically the central message of this paper: Don't be fooled by the traditional definition of 'ductile,'" he said. "At the nanoscale, things can happen differently."

|