| Jan 11, 2017 |

Environmental friendly methodology for production of ethanol from bagasse by sequential bio-processing

|

|

(Nanowerk News) Biomass based materials are considered as an essential sources for bio refining industries for the production of ethanol, so as to utilize them for several applications (energy and other products).

|

|

Among them, sugarcane bagasse (from cane sugar) and soyabean hull (from soya bean industry) are highly favoured, as they contain major quantity of lignocellulose, which could yield in feedstock for subsequent production of ethanol and other reducing sugars.

|

|

Furthermore, these substances are cheap and available in abundance, hence considered as a potential renewable alternative to other sources, thereby contributing to the development of bio refinery based industries.

|

|

For the production of feedstock for ethanol production, the current industrial methods employ the usage of synthetic chemicals by (physical, chemical and physio-chemical methods). The first step is pre-treatment of these substrates followed by the degradation of crystalline structure of this lignocellulose and then exploiting the amorphous areas, so as to improve the efficiency of production.

|

|

However, all these methods add significant cost to the overall process and contribute to the environmental pollution. Several attempts are still in their way to improve the production, by adopting different strategies.

|

|

In a research work by The University of Manchester academics (Prof. Colin Webb's research group at the School of Chemical Engineering), a new methodology have been developed, that significantly reduces the time and cost involved in these reducing sugars (ethanol and other alcohols) production method.

|

|

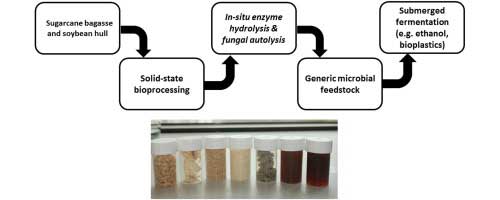

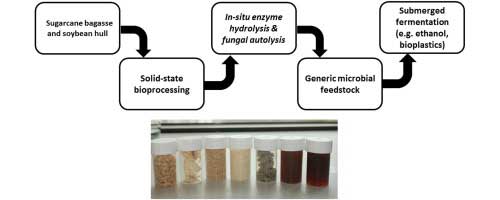

| Production of a generic microbial feedstock for lignocellulose biorefineries through sequential bioprocessing. (© Elsevier)

|

|

In their paper in Bioresource Technology ("Production of a generic microbial feedstock for lignocellulose biorefineries through sequential bioprocessing"), they have shown that the fungus Trichoderma longibrachiatum, on added to the lignocellulosic substrate (sugarcane bagasse and soyabean hull) has resulted in the production of feedstock for ethanol yield.

|

|

The mechanism explained is that this fungus, degrades lignocellulosic substances with the simultaneous release of enzymes, producing feed stock and then this is hydrolysed for ethanol production. This has a significant advantage over the chemical pre-treatment methods, as this eliminates the need for pre-treatment step, subsequently reducing the number of stages in a processing step. Further, this feedstock production through this single step process adds more simplicity to the overall process.

|

|

This eco-friendly methodology is predicted to surpass current commercial production, which could subsequently eliminate the expensive pre-treatment method and relatively reduce the processing time. Comparing to the studies made before, the yield of ethanol per mass of raw material is quite comparable to the chemical pre-treatment strategies, around 0.04 g of product per gram of raw material for this method (and 0.01 to 0.1 g from the literature).

|

|

Also this feedstock produced other nutrients such as aminoacids, peptides and other micronutrients apart from ethanol which could be used for other purposes. Though this microbial feedstock product by sequential bioprocessing method, offers significant advantages, process optimization, volumetric productivity, concentration and decreased levels of enzyme production, limits the overall process from complete commercial exploitation.

|