Understanding Nanofibers: Their Production, Properties, and Applications

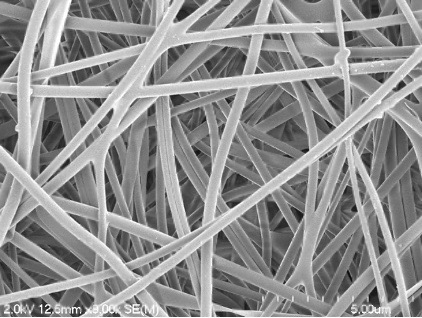

Definition: Nanofibers are fibers with diameters in the nanometer range, typically less than 100 nm. They are known for their high surface area to volume ratio, flexibility in surface functionalities, and superior mechanical performance compared to their macroscale counterparts. This makes nanofibers highly sought after for a variety of applications, from filtration and tissue engineering to energy storage and sensors.

Production Techniques

Nanofibers can be fabricated through various methods, each with its unique advantages and applications. The most common techniques include:

- Electrospinning: The most widely used method for producing nanofibers, electrospinning uses an electric field to draw charged threads of polymer solutions or melts into fine fibers. This method offers versatility in controlling fiber diameter, orientation, and composition.

- Forcespinning: A newer technique that utilizes centrifugal force to draw fibers from polymer melts or solutions, offering an efficient and scalable alternative to electrospinning.

- Phase separation: This technique involves the separation of a polymer solution into two phases, leading to the formation of a nanofibrous structure upon the removal of one phase.

- Template synthesis: In this method, nanofibers are synthesized within the pores of a template, which is later removed, leaving behind a nanofibrous structure.

Unique Properties

Nanofibers exhibit several unique properties due to their nanoscale dimensions:

- High Surface Area: Their high surface area to volume ratio makes them ideal for applications requiring enhanced surface interactions, such as catalysis and filtration.

- Mechanical Strength: Despite their small size, nanofibers can exhibit high tensile strength and flexibility.

- Functionalization: Surface properties of nanofibers can be easily modified to introduce specific functionalities, enabling their use in a wide range of applications.

Applications

Nanofibers find applications in numerous fields, leveraging their unique properties:

- Filtration: Utilized in air and water filtration systems for removing nanoparticles and pathogens due to their high surface area and porosity.

- Tissue Engineering: Their structure mimics that of the extracellular matrix, making them suitable for creating scaffolds that support cell growth and tissue regeneration.

- Drug Delivery: Nanofibers can be engineered to control the release of drugs, improving the efficiency and targeting of treatments.

- Energy Storage: Used in batteries and supercapacitors for their high surface area, which enhances electrode performance.

- Sensors: Applied in the development of highly sensitive and selective sensors for environmental monitoring, healthcare, and industrial processes.

Difference Between Nanofibers and Nanowires

Nanofibers and nanowires are both nanoscale materials, but they have distinct characteristics and applications due to their differing compositions and physical properties. Here's a brief overview of their main differences:

Composition and Structure

- Nanofibers are typically made from polymers or composite materials and are characterized by their long, thin fibrous structure. They can be flexible or rigid depending on the material composition and are often used in applications that leverage their high surface area and porosity.

- Nanowires, on the other hand, are made from inorganic materials such as metals or semiconductors. They have a crystalline structure and are usually more rigid than nanofibers. Nanowires are known for their electrical, thermal, and optical properties, which are exploited in electronics, photonics, and nanoscale sensing applications.

Electrical Conductivity

- The electrical conductivity of nanofibers varies widely and depends on the specific materials used. Some nanofibers, especially those made from conducting polymers or carbon-based materials, can exhibit good electrical conductivity.

- Nanowires are generally highly conductive or semiconductive due to their inorganic, crystalline nature. This makes them integral components in the fabrication of nanoscale electronic devices, including transistors, sensors, and photovoltaic cells.

Applications

- Nanofibers are predominantly used in applications that benefit from their high surface area and flexibility, such as filtration, tissue engineering, drug delivery, and protective clothing.

- Nanowires find their applications mainly in the field of electronics and photonics, including as conductive paths in electronic circuits, in nanoscale lasers, and as sensors in various detection systems.

In summary, while both nanofibers and nanowires operate at the nanoscale, their differences in composition, structure, and electrical properties steer them towards distinct sets of applications in various fields of technology and research.

Challenges and Future Directions

While nanofibers offer promising potential across various fields, challenges such as scalability of production, cost-effectiveness, and environmental impact need to be addressed. Ongoing research focuses on developing sustainable materials and processes, improving the functionality and application of nanofibers in emerging technologies such as wearable electronics and smart textiles.